42 Measuring and Weighing

Michael Hrycay

Learning Objectives

Demonstrate the measuring/weighing of materials

The Importance of Weighing in Food Manufacturing

Why Weigh?

Weighing is an essential part of the food production process. Weighing applications can be found across every processing plant. These weighing applications can be found as early in the production process as the weighing of incoming products on the receiving dock to the weighing and labeling of finished goods’ boxes going into inventory. Weighing ingredients for quality compliance is extremely important. This is because ingredients must be weighed to fulfill product recipe specifications and quality requirements. Measuring ingredients with extreme accuracy ensures they are distributed equally, and the product tastes the same in every batch.

Food scales help processors adhere to production requirements and reduce the risk of creating out-of-spec product. Out-of-spec product can jeopardize the health of consumers and subject processors to fees for non-compliance with food service regulations. To avoid out-of-spec products, processors must invest in accurate, high-quality food scales.

Scales for the Food Processing Industry

Floor Scales

Floor scales can be found in multiple areas of a food processing plant. They are used on receiving docks to weigh incoming pallets of product. This ensures what was received matches what was ordered. Floor scales are also found in production areas of the plant. Processors use them to weigh larger products like combos, steel bins of product, and trollies.

Bench Scales

The ideal method of weighing for food production is using a bench scale that has high readability and a lower capacity. In other words, bench scales for food processing should be highly precise and able to weigh small individual food items with a high degree of accuracy. To achieve optimal results, processors should avoid scales that weigh in larger increments, for example, five pounds instead of one gram.

Counting Scales

Counting scales allow processors to efficiently weigh a high volume of identical parts. This is useful in food production where the same ingredient may be used repeatedly in a batch. Using a counting scale to weigh ingredients ensures the final product is consistent and of high quality.

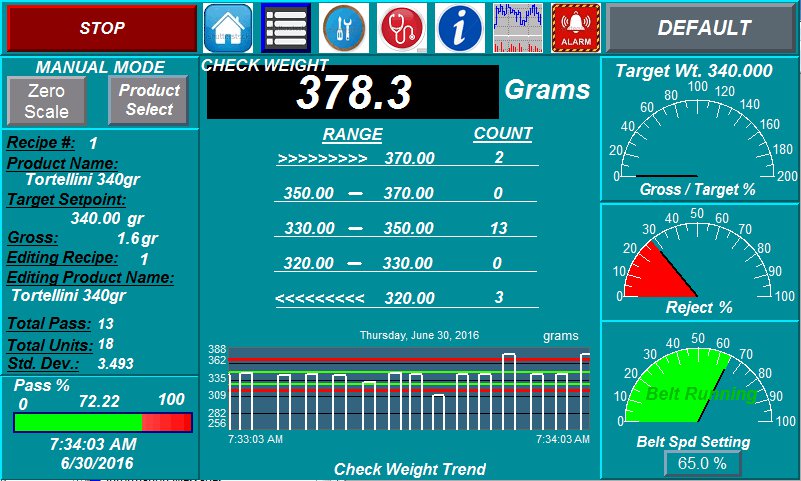

Checkweighers

A useful weighing feature that enhances efficiency in packaging and sorting procedures is a checkweighing scale, or simply “checkweigher.” Checkweighers allow users to select a weight range and, in turn, accept or reject a product based on whether or not its weight falls within the predetermined range.

Testing Food Processing Scales

Scales are often the last piece of equipment to be suspected—or inspected—when there is an issue related to out-of-spec product. For this reason, scale inspection and testing should be scheduled regularly to meet the accuracy requirements for a product. The higher the accuracy requirement, the more likely it is the material being weighed will be out of tolerance, and the more frequent the testing of the scale should occur.

When testing the accuracy of food processing scales, it is important to consider external factors that could impact your equipment’s performance, such as food buildup. Avoid inaccurate weight readings by clearing the scale of food or liquid that may have accumulated during production. Precautionary measures such as frequent cleaning, combined with regular scale testing, can reduce the likelihood of out-of-spec products.

References

Cumpton, A. (2020, June 3). Mini-blog: The importance of weighing in food manufacturing. Carlisle Technology Website. Retrieved October 3, 2022, from https://www.carlisletechnology.com/blog/mini-blog-the-importance-of-weighing-in-food-manufacturing