7 Chapter 6: Portable Fire Extinguishers

Introduction

Welcome! Tansi!

Essentials of Firefighting

Chapter Objectives

- Distinguish among the five classifications of portable fire extinguishers. [4.3.16]

- Distinguish among the various types of portable fire extinguishers. [4.3.16]

- Describe the process of selecting and using a portable fire extinguisher. [4.3.16]

- Skill Sheet 6-1: Extinguish an incipient Class A, B, or C fire with a portable fire extinguisher. [4.3.16]

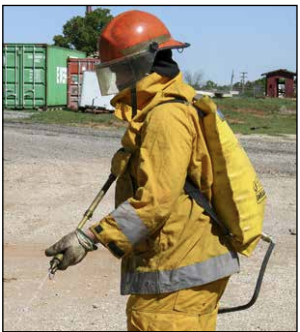

Fixed facilities, such as residences, retail stores, and businesses; onboard ships and aircraft; and vehicles including fire apparatus may all have portable fire extinguishers on location. Portable fire extinguishers are primarily intended for occupants to use on small, incipient fires or on fires in the early growth stage. Firefighters may also use portable fire extinguishers in a variety of circumstances (Figure 6.1). Firefighters must learn about portable fire extinguishers for use on the job as well as to teach members of the community to use them properly.

According to NFPA 1001, those qualified at the Firefighter I level must know the following about portable fire extinguishers:

- Fire classifications

- Risks associated with each class of fire

- Operating methods of portable fire extinguishers

- Limitations of portable fire extinguishers

The Fire Fighter I must be able to:

- Select the appropriate extinguisher for the size and type of fire

- Safely carry portable fire extinguishers

- Approach fire with portable fire extinguishers

- Operate portable fire extinguishers

This chapter describes the various types of portable fire extinguishers, how they are rated, and how to inspect them. Also explained are the steps involved in the selection and use of portable fire extinguishers.

Now What?

Let’s get learning!

Lesson 1

Outcomes:

- Distinguish among the five classifications of portable fire extinguishers.

Classifications of Portable Fire Extinguishers

Portable fire extinguishers are classified according to the type of fire that each is designed to extinguish. They are often suitable to extinguish more than one class of fire while some are only designed for a particular class of fire.

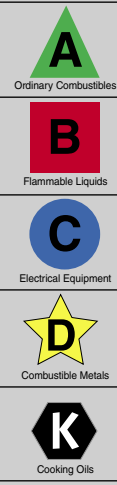

There are five classes of portable fire extinguishers to match the five classes of fire: Class A, B, C, D, and K. Portable fire extinguishers are identified by the class letter or combination of letters for which the extinguisher is rated. The three most common combinations are Class A-B-C, Class A-B, and Class B-C.

All new portable fire extinguishers must be labelled with the appropriate letters and/or symbols. An extinguisher should be used only for the fire type(s) for which it is intended. The appropriate portable fire extinguisher to use on a given fire depends on what is burning. Certain extinguishing agents are only effective on certain classes of fire or fuels.

Class A and B extinguishers are classified with both letter and numerical rating systems. For example, a common-sized extinguisher, such as the multipurpose extinguisher rated 4-A 20-B:C, should extinguish a Class A fire that is 4 times larger than a 1-A fire, extinguish approximately 20 times as much Class B fire as a 1-B extinguisher, and extinguish a deep-layer flammable liquid fire of 20 square feet (1.8 m2) in area. It must also be nonconductive, so it is safe to use on fires involving energized electrical equipment. The ratings for each separate class of extinguisher do not affect each other.

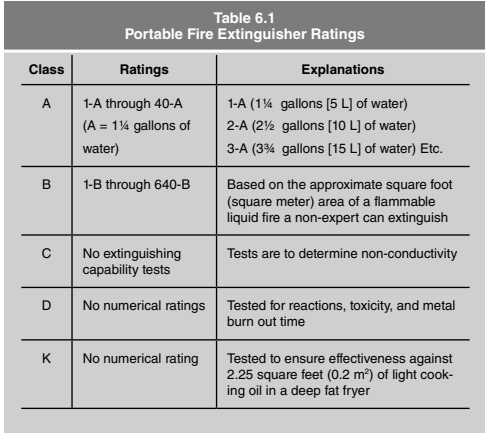

The classification and numerical rating system is based on tests conducted by Underwriters Laboratories (UL) and Underwriters Laboratories of Canada (ULC). These tests determine the extinguishing capability for each size and type of extinguisher. Table 6.1 compares the ratings of each class of portable extinguisher.

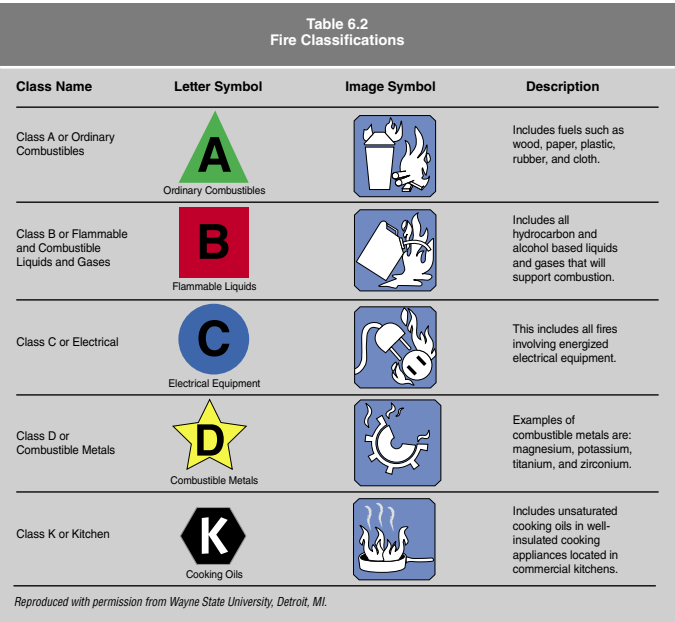

Portable fire extinguishers are identified in two ways. One system uses geometric shapes of specific colours with the class letter shown within the shape. The second system uses pictographs to make the selection of the most appropriate fire extinguishers easier. It also shows the types of fires on which extinguishers should not be used. Table 6.2 compares the two identification systems. More information on extinguisher ratings will be provided in the following sections.

Class A

Class A fires involve ordinary combustibles such as (Figure 6.2):

- Textiles

- Plastics

- Paper

- Rubber

- Wood

All of these fuels can be extinguished with water and water-based agents like Class A foam. Dry chemicals will also extinguish fires fuelled by Class A materials.

Class A portable fire extinguishers are rated from 1-A through 40-A. The Class A rating of extinguishers is primarily based on the amount of water and the duration and range of the discharge used in extinguishing test fires. To calculate the water capacity of a Class A extinguisher, multiply the number in front of the “A” by 11⁄4 gallons (5 L). For a 1-A rating, 11⁄4 gallons (5 L) of water are required. A 2-A rating requires 21⁄2 gallons (10 L) or twice the 1-A capacity. 3-A rating requires 33⁄4 gallons [15 L] and so on.

Class B

Class B fires involve flammable and combustible liquids and gases (Figure 6.3). Agents used to extinguish Class B fires include carbon dioxide (CO2), dry chemicals, and Class B foam.

Flammable and combustible liquids and gases include:

- Alcohol

- Lubricating oils

- Gasoline

- Liquefied petroleum gas (LPG)

Class B portable fire extinguishers are classified with numerical ratings ranging from 1-B to 640-B. The rating is based on the approximate square foot (square meter) area of a flammable liquid fire that a non-expert operator can extinguish using one full extinguisher. The nonexpert operator is expected to extinguish 1 square foot (0.09 m2) for each numerical rating or value of the extinguisher rating.

Class C

Class C fires involve energized electrical equipment (Figure 6.4). Water and water-based agents conduct electrical current and cannot be used on Class C fires until the electricity has been shut off. Class C extinguishing agents will not conduct electricity which makes them suitable for electrical fires. Once the power supply has been turned off or disconnected, firefighters can treat the fire as a Class A or B fire.

Fire extinguishing capability tests are not specifically conducted for Class C ratings. The Class C rating confirms that the extinguishing agent will not conduct electricity. The Class C rating is assigned in addition to a rating for Class A and/or Class B fires. To determine extinguishing ability, check the Class A and/or Class B rating.

Class D

Class D fires are those involving combustible metals and alloys such as (Figure 6.5):

- Titanium

- Lithium

- Magnesium

- Sodium

- Potassium

Magnesium fires

Magnesium fires can be identified by the bright white emissions during the combustion process. Some common uses of magnesium are in:

- Cameras

- Laptops

- Luggage

- Metal box springs for beds

- Wheels and transmission components for automobiles

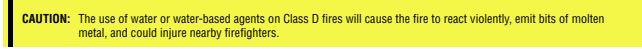

Class D dry powder extinguishers work best on these types of fires. Do not confuse dry powder extinguishers with dry chemical units used on Class A, B, and C fires. Only use extinguishers that are rated for Class D fires – whether liquid or powder – to extinguish metal fires.

Test Fires

Test fires for establishing Class D extinguisher ratings vary with the type of combustible metal tested. Testers consider the following factors during each test:

- Reactions between the metal and the agent

- Toxicity of the agent

- Toxicity of the fumes produced and the products of combustion

- Time to allow the metal to burn completely without fire suppression compared to the time to extinguish the fire using the extinguisher

When an extinguishing agent is determined to be safe and effective for use on a combustible metal, manufacturers include the application instructions on the faceplate of the extinguisher; they do not give a numerical rating. Class D agents do not receive a rating for use on other classes of fire.

Class K

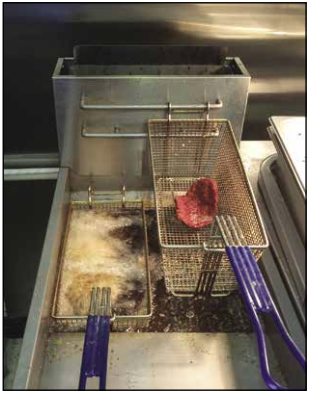

Class K fires involve combustible cooking oils such as vegetable or animal fats and oils that burn at extremely high temperatures (Figure 6.6). Firefighters may encounter these fuels in private homes, commercial and institutional kitchens, and industrial cooking facilities. Wet chemical systems and portable fire extinguishers are used to control and extinguish Class K fires.

Class K-rated extinguishers work because of saponification. Saponification converts the fatty acids or fats in the following oils to a soapy film:

- Vegetable oil

- Canola oil

- Peanut oil

- Other oils with little or no fatty acids

A fire in a high temperature combustible cooking oil unit such as this one would be labeled a Class K fire. Courtesy of Steven A. Stokely, Sr. and Midwest Kosher Deli, South Bend, IN.

Wet chemical agents containing an alkaline mixture, such as potassium acetate, potassium carbonate, or potassium citrate, suppress the vapours and smother the fire. Agents capable of extinguishing a fire from a deep fryer using these light oils with a surface area of 2.25 square feet (0.2 m2) meet the minimum criteria for Class K rating.

Key Terms

Class A Fire: Fires involving ordinary combustibles such as wood, paper, cloth, and similar materials.

Class B Fire:Fires of flammable and combustible liquids and gases.

Class C Fire:Fires involving energized electrical equipment.

Class D Fire:Fires of combustible metals such as magnesium, sodium, and titanium.

Class K Fire: Fires in cooking appliances that involve combustible cooking media, such as vegetable or animal oils and fats; commonly occurring in commercial cooking facilities such as restaurants and institutional kitchens.

Test Your Knowledge!

Lesson 2

Outcomes:

- Distinguish among the various types of portable fire extinguishers.

Types of Portable Fire Extinguishers

Fire Extinguishers are rated according to the type of fire they will extinguish. Portable fire extinguishers are also rated according to the type of extinguishing agent and the mechanism used to expel the contents.

Extinguishing agents use at least one of the following methods to extinguish fire:

- Smothering: Excluding oxygen from the burning process

- Cooling: Reducing the burning material below its ignition temperature

- Chemical flame inhibition: Interrupting the chemical chain reaction in the burning process

- Saponification: Forming an oxygen-excluding soapy foam surface

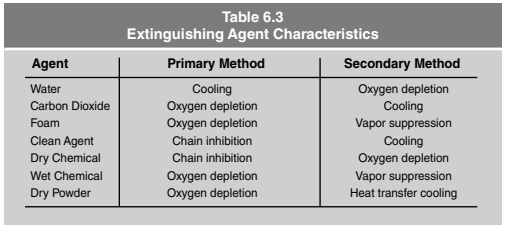

Table 6.3 lists the primary and secondary extinguishing methods of various extinguishing agents. Smothering extinguishing agents will not work on materials that contain their own oxidizing agent. For example, applying water-based foam (a smothering agent) to a fire in magnesium or other combustible metals will cause the fire to flare and intensify.

**NOTE: Water-type extinguishers must be protected against freezing if exposed to temperatures lower than 40°F (4°C). Protection options include adding antifreeze to the water or storing them in warm areas.**

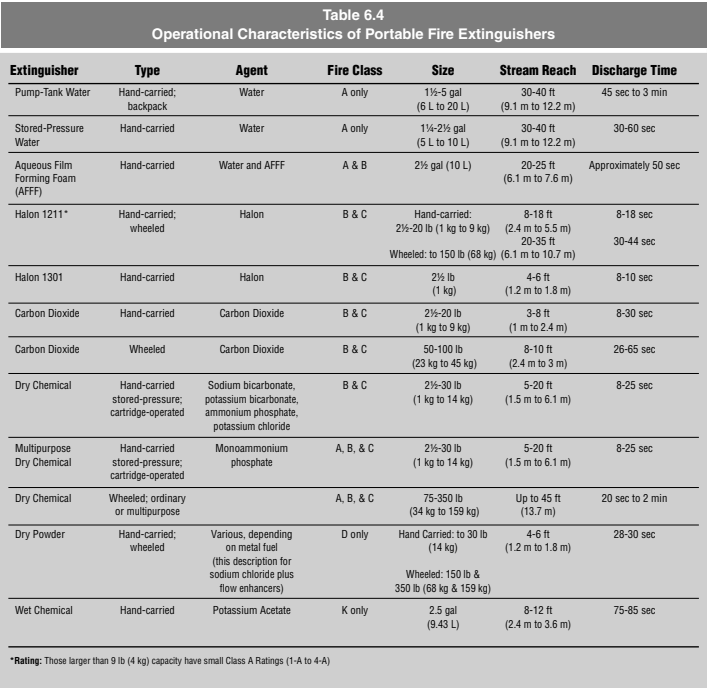

Table 6.4 shows the operational characteristics of different types of portable fire extinguishers.

All portable fire extinguishers expel their contents using one of the following mechanisms:

- Manual pump: The operator physically applies pressure to a pump that increases pressure within the container which forces the agent out a nozzle at the end of a hose.

- Stored pressure: Compressed air or inert gas within the container forces the agent out a nozzle at the end of a hose when the operator presses the handle.

- Pressure cartridge: A separate cartridge on the side of the container contains inert gas. When the operator punctures the cartridge seal, the expellant enters the container and forces the agent out a nozzle on the end of a hose.

Common portable fire extinguishers include:

- Pump-type water extinguishers

- Stored-pressure extinguishers

- Aqueous film-forming foam (AFFF) extinguishers

- CO2 extinguishers

- Dry powder extinguishers

- Stored-pressure water extinguishers

- Wet chemical stored-pressure extinguishers

- Clean agent extinguishers

- Dry chemical extinguishers

Pump-Type Water Extinguishers

Pump-type water extinguishers are intended primarily for use on ground cover fires although they may also be used for small Class A fires. Operators usually wear pump-type water extinguishers on their backs and use a manually operated slide pump. The nozzle produces a straight stream, fog, or water-mist pattern (Figure 6.7).

Stored-Pressure Water Extinguishers

Stored-pressure water extinguishers, also called air-pressurized water (APW) extinguishers or pressurized water extinguishers, are useful for all types of small Class A fires (Figure 6.8). They are also useful for extinguishing confined hot spots during overhaul operations.

These tanks store water along with compressed air or nitrogen. A gauge located on the valve assembly displays the extinguisher’s pressure level. When operators activate the operating valve, the stored pressure forces water up the siphon tube and out through the hose.

Some manufacturers add Class A foam concentrate to pump-type or stored-pressure water extinguishers to increase their effectiveness. The Class A foam concentrate serves as a wetting agent and can aid in extinguishing deep-seated fires in upholstered furniture or vehicle seats and wildland fires in densely matted vegetation. Class A foam concentrate reduces the surface tension of water, allowing the water to quickly penetrate the surface.

Stored-Pressure Water-Mist Extinguishers

Similar in appearance to standard stored-pressure water extinguishers, stored-pressure water-mist extinguishers use deionized water as the agent and nozzles that produce a fine spray instead of a solid stream. Because impurities in water make it conduct electricity, the deionized water also makes these Class A extinguishers safe to use on energized electrical equipment (Class C). The fine spray also enhances the water’s cooling and soaking characteristics and reduces the scattering of burning materials.

Stored-Pressure Wet Chemical Extinguishers

Stored-pressure wet chemical fire extinguishers are similar in appearance to standard stored-pressure water extinguishers. They are intended for use on Class K fires involving cooking fats, greases, and vegetable and animal oils in commercial kitchens (Figure 6.9). These fire extinguishers contain a special potassium-based, low-pH agent formulated to operate on the principle of saponification in which the agent combines with the oils to create a soapy foam surface over the cooking appliance. Some fire departments carry Class K extinguishers on their apparatus.

Aqueous Film Forming Foam (AFFF)

Extinguishers Aqueous film-forming foam (AFFF) extinguishers are intended for Class B fires. They are particularly useful in combating fires in or suppressing vapours from small liquid fuel spills (Figure 6.10).

Key Takeaways Uses: Class B firesUseful in combating fires or suppressing vapors from small fuel spillsMost effective on static pools of flammable liquidsNot suitable for Class C, D, or K fuelsNot suitable for flowing fuels or fuel under pressure

Stored-Pressure Wet Chemical Extinguishers Key TakeawaysWet chemicalClass K firesPotassium-based, low-pH agent that extinguishes by saponificationCarried on some apparatus

**NOTE: Some manufacturers market AFFF foam concentrates that can be used on Class A fires.**

AFFF extinguishers differ from stored-pressure water extinguishers in two ways:

- The AFFF extinguisher tank contains a specified amount of AFFF concentrate mixed with the water to produce a foam solution.

- It has an air-aspirating foam nozzle that aerates the foam solution, producing better-quality foam than a standard extinguisher nozzle provides.

The water/AFFF solution is expelled using compressed air or nitrogen stored in the tank with the solution. The resulting finished foam floats on the surface of fuels that are lighter than water. The film of finished foam creates a vapour seal that extinguishes the flame and prevents reignition. To avoid disturbing the foam blanket when applying the foam, do not apply the foam directly onto the fuel; instead, allow it to rain down gently onto the fuel’s surface or deflect the foam off a nearby object or surface.

AFFF extinguishers are most effective on static pools of flammable liquids. They are not suitable for fires in Class C, Class D, or Class K fuels. They are not suitable for such situations as fuel flowing down from an elevated point and fuel under pressure spraying from a leak.

Clean Agent Extinguishers

Clean agents in halotron extinguishers effectively cool and smother fires in Class A and B fuels and inhibit the sustained chemical reaction in Class C fuels. The agents are nonconductive and can extinguish energized electrical equipment fires (Figure 6.11).

They have been developed to replace Halons, also known as halogenated extinguishing agents. Halons were extremely effective for extinguishing fires in computer rooms, aircraft engines, and areas that contain materials that could easily be damaged by water or dry chemical agents. However, halogenated extinguishing agents have a damaging effect on the atmosphere’s ozone layer.

Halotron is an alternative clean agent that does not harm the ozone layer. Halotron extinguishers are a U.S. Environmental Protection Agency (EPA) approved alternative to Halons.

Carbon Dioxide (CO2) Extinguishers

Carbon dioxide (CO2) fire extinguishers are available as both handheld and wheeled units. CO2 extinguishers are most effective in extinguishing Class B and Class C fires. They discharge a gas with a limited reach. Wind will disperse the extinguishing agent. They do not require freeze protection (Figure 6.12).

Carbon dioxide CO2 extinguishers store carbon dioxide under its pressure as a liquefied gas. The extinguishers discharge the agent through a plastic or rubber horn on the end of either a short hose or tube. The gaseous discharge usually forms dry ice crystals or carbon dioxide “snow.” Shortly after discharge, this snow changes from a solid to a gas without becoming a liquid. The CO2 though CO2 gas displaces available oxygen and smothers the fire. Even discharged at sub-zero temperatures, it has little if any cooling effect on fires. Carbon dioxide does not suppress the surface vapours of fuel; therefore, fuels may reignite.

Wheeled CO2 Units

- Wheeled CO2 units are considerably larger than handheld units.

- Wheeled CO2 units usually have 50-to 100-pound (25 to 45 kg) capacities.

- Wheeled units are most used in airports and industrial facilities.

- After operators wheel the unit to the fire, they must deploy or unwind the hose (usually less than 15 feet [5 m] long) from the unit before use.

- Otherwise, the principle of operation is the same as that of smaller handheld units.

Dry Chemical Extinguishers

The terms dry chemical and dry powder are often incorrectly used interchangeably. Dry chemical agents are for use on Class A-B-C fires and/or Class B-C fires; dry powder agents are only for use on Class D fires. Dry chemical extinguishers are among the most common portable fire extinguishers in use today.

There are two basic types of dry chemical extinguishers:

- Regular B-C-rated

- Multipurpose and A-B-C-rated (see Extinguisher Rating System section)

Unless specifically noted in this section, the characteristics and operation of both types of dry chemical extinguishers are exactly the same.

The following are commonly used dry chemicals:

- Sodium bicarbonate

- Potassium bicarbonate

- Urea-potassium bicarbonate

- Potassium chloride

- Monoammonium phosphate

Manufacturers mix dry chemical agents with additives that make the agents moisture-resistant and prevent them from caking (drying or hardening into a mass). This process keeps the agents ready for use and free-flowing even after being stored for long periods. Because they do not cake, the application of agents may result in a cloud of airborne particulate. While the agents themselves are nontoxic and generally considered safe to use, the cloud may reduce visibility and create respiratory problems.

On Class A fires, direct the agents at the fuel in order to cover it with the chemical. Once the flames have been knocked down, operators should apply the agent intermittently as needed on any smouldering areas.

Many dry chemical agents can be mildly corrosive to all surfaces. Some dry chemicals are compatible with foam, but others are not. For example, monoammonium phosphate and some sodium bicarbonate agents will cause the foam blanket to deteriorate when applied with or after foam to a Class B fire or spill.

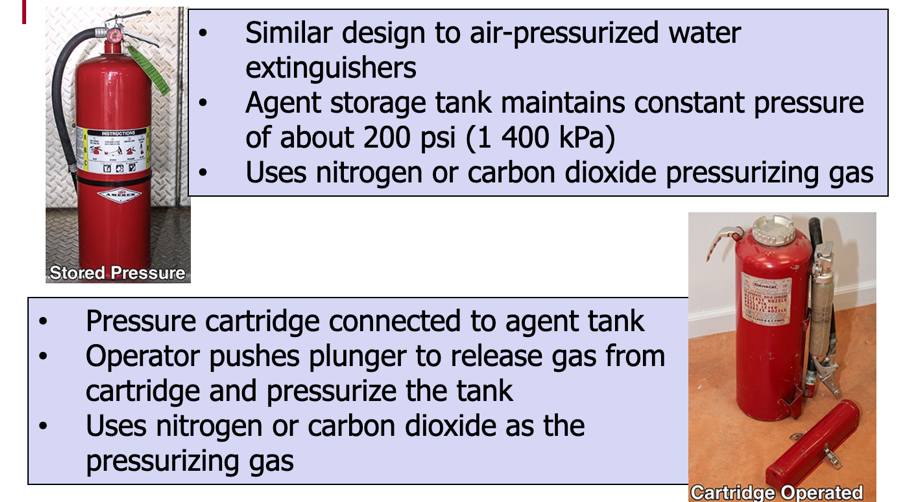

Handheld Units

There are two basic designs for handheld dry chemical extinguishers: cartridge-operated and stored-pressure. The stored-pressure type is similar in design to the air-pressurized water extinguisher. The agent storage tank maintains a constant pressure of about 200 psi (1 400 kPa). Cartridge-operated extinguishers employ a pressure cartridge connected to the agent tank. Operators push a plunger to release the gas from the cartridge and pressurize the agent tank. Both cartridge-operated and stored-pressure dry chemical extinguishers use either nitrogen or carbon dioxide as the pressurizing gas (Figure 6.13).

Wheeled Units

Dry chemical wheeled units are larger versions of the handheld units. They are rated for Class A, B, and C fires based on the dry chemical in the unit. As with the handheld units, the extinguishing agent is kept in one tank and the pressurizing gas is stored in a separate cylinder.

After positioning the extinguisher at a fire, and before discharging the extinguishing agent, the operator should stretch out the hose completely. Once the agent storage tank and hose are charged, it can make removing the hose more difficult and the powder can clog in any sharp bends in the hose.

Operators should introduce the pressurizing gas into the agent tank and allow it a few seconds to fully pressurize the tank before opening the nozzle. The operator should be prepared for a significant nozzle reaction when the nozzle is opened. The agent is applied in the same manner as described for the handheld, cartridge-type dry chemical extinguishers (Figure 6.14).

Operators should introduce the pressurizing gas into the agent tank and allow it a few seconds to fully pressurize the tank before opening the nozzle. The operator should be prepared for a significant nozzle reaction when the nozzle is opened. The agent is applied in the same manner as described for the handheld, cartridge-type dry chemical extinguishers (Figure 6.14).

Dry Powder Extinguishers

Fires involving Class D combustible metals require special dry powder extinguishing agents and application techniques (Figure 6.15). No single extinguishing agent will control or extinguish fires in all combustible metals. Some agents extinguish fires in several metals; others extinguish fires in only one type of metal. Some powdered agents can be applied with portable extinguishers, but others must be applied with either a shovel or a scoop. The manufacturer’s technical sales literature describes the appropriate application technique for any given dry powder. You should be thoroughly familiar with the information that applies to any agent carried on your apparatus.

Class D portable fire extinguishers come in both handheld and wheeled models. Whether applying a particular dry powder with an extinguisher or with a scoop, operators must apply the agent in sufficient depth to completely cover the burning area. Operators should apply the agent gently to avoid breaking any crust that may form over the burning metal. If the crust breaks, the fire may flare and expose more uninvolved material to combustion. Avoid scattering the burning metal. Additional applications may be necessary to cover any hot spots that develop.

To extinguish a fire fueled with a small amount of burning metal on a combustible surface, first cover the fire with powder. Then, spread a layer of powder 1 to 2 inches (25 to 50 mm) deep nearby and shovel the burning metal onto this layer, adding more powder as needed. After extinguishment, leave the material undisturbed until the mass has cooled completely before attempting disposal.

Key Takeaways

Dry Powder Extinguisher

Uses:

- Class D fires

- No agent will work for all combustible metals

Function and application:

- Powdered agents applied with handheld or wheeled extinguishers or a shovel or scoop

- Completely cover burning area with the agent

- Apply agent gently

- Avoid scattering burning material

- Additional applications as needed to cover hot spots

- After extinguishment, leave material undisturbed until it is completely cooled

Selecting and Using Portable Fire Extinguishers

In most cases, your supervisor will decide on the need to use a portable fire extinguisher and will tell you the correct type to select and use. If you are the only one present and must make your selection, there are several factors to consider when deciding which portable fire extinguisher to select for the situation. In addition, there are a few things to remember when using the selected extinguisher.

This section explains these considerations. This information is also important when you are instructing others in the selection and use of extinguishers.

Selecting the Proper Fire Extinguisher

Select extinguishers that minimize the risk to life and property and are effective in extinguishing the fire. To make this selection, consider the following factors:

- Classification of the burning fuel

- Hazards to be protected against

- Atmospheric conditions

- Ease of handling the extinguisher

- Rating of the extinguisher

- Size and intensity of the fire

- Availability of trained personnel to operate the extinguisher

- Any life hazard or operational concerns

Even though fires in electronics or computer equipment are Class C fires, you should select clean agents or carbon dioxide extinguishers to fight fires in highly sensitive computer equipment. Dry chemicals normally used for electrical fires will leave a residue that could potentially do more damage to the computers than the fire itself.

Using Portable Fire Extinguishers

Portable fire extinguishers come in many types and sizes. While the operating procedures of each type of extinguisher are similar, you should become familiar with the detailed instructions found on the label of the extinguisher.

**NOTE: Wear appropriate personal protective equipment when using fire extinguishers. **

A visual inspection of the extinguisher should be conducted before it is used.

After selecting the appropriate size and type of extinguisher for the situation, make a quick visual inspection. This inspection is necessary to ensure that the extinguisher is charged and operable. This check may protect you from injury from a defective or depleted extinguisher.

When inspecting an extinguisher immediately before use, check the following (Figure 6.16):

- External condition: No apparent damage

- Hose/nozzle: In place

- Weight: Feels as though it contains agent

- Pressure gauge (if available): If present, should register a reading within the operable range.

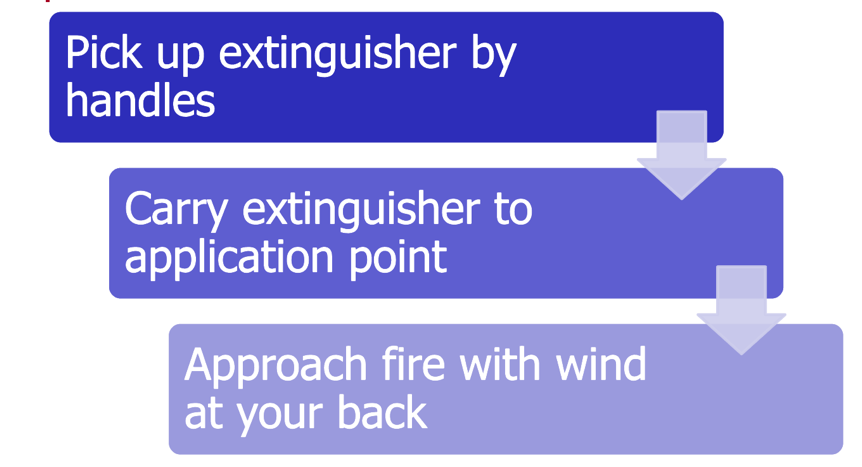

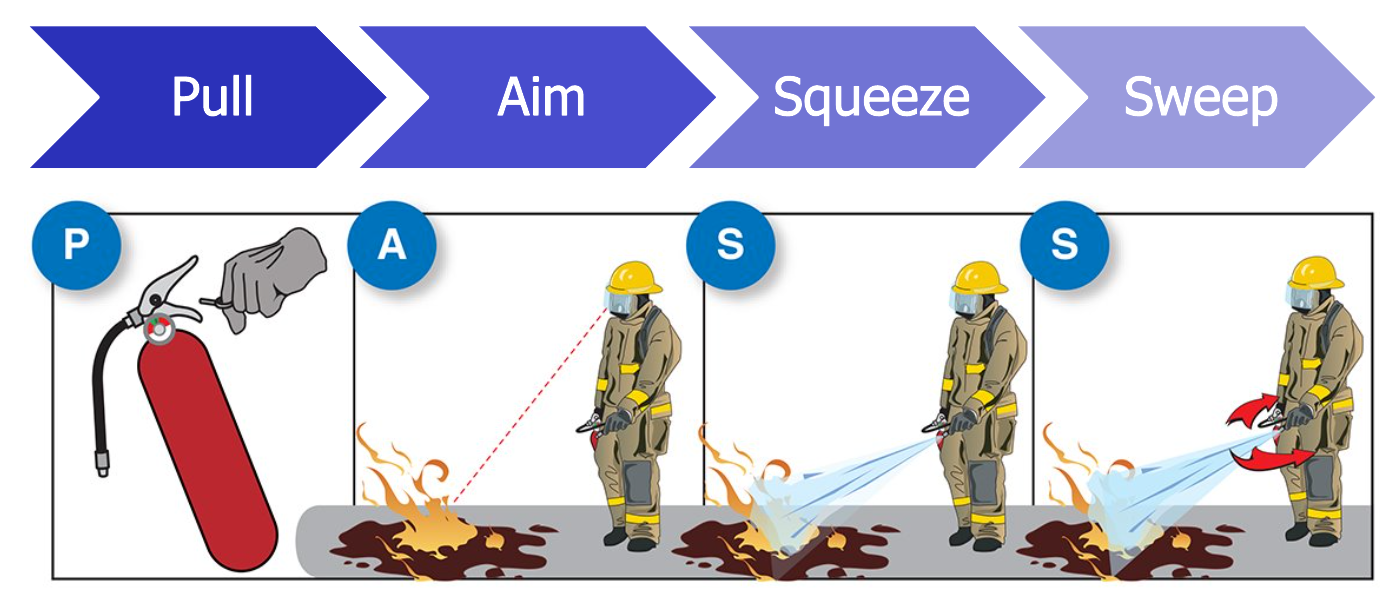

After performing the visual inspection, pick up the extinguisher by its handles and carry it to the point of application. Approach the fire from upwind (wind at your back). Once in position to attack the fire, use the PASS application method (Figure 6.17):

After performing the visual inspection, pick up the extinguisher by its handles and carry it to the point of application. Approach the fire from upwind (wind at your back). Once in position to attack the fire, use the PASS application method (Figure 6.17):

- P – Pull the pin breaking the thin wire or plastic seal.

- A – Aim the nozzle at the base of the fire.

- S – Squeeze the handles together to release a short burst to test the extinguisher, then squeeze continuously to release the agent.

- S – Sweep the nozzle back and forth to cover the burning material.

Skill Sheet 6-1 depicts the correct application of the P-A-S-S method of operating different types of portable fire extinguishers.

Considerations Related to Suppressing Incipient Fires

Considerations relating to suppressing incipient fires of all classes include:

- Remember that a portable extinguisher is a first-aid firefighting appliance and does not take the place of an appropriate-sized hose line.

- Be sure the extinguishing agent reaches the fire — if it cannot, the agent will be wasted.

- Ensure that there is a clear exit for immediate escape should you need it.

- Smaller extinguishers require a closer approach to the fire than larger units, thus radiant heat or smoke may prevent you from getting close enough for the agent to reach the fire.

- Adverse winds can limit the reach of an agent.

- Operating an extinguisher close to the fire can sometimes scatter lightweight solid fuels or penetrate the surface of liquid fuels.

- Apply the agent from a point where it reaches but does not disturb the fuel surface. Releasing the handles will stop the flow of the agent.

- After the fire diminishes, you may move closer to achieve final fire extinguishment.

- If extinguishment is not achieved after an entire extinguisher has been discharged onto the fire, withdraw, and reassess the situation.

- If liquid fuel is burning, it may be necessary to either apply the appropriate type of foam through a hoseline or simultaneously attack the fire with more than one portable fire extinguisher.

- For fires involving an energized electrical component (Class C), attempt to shut off the electricity to the component before attempting to extinguish the fire.

- If more than one extinguisher is used simultaneously, work in unison with the other firefighters and maintain a constant awareness of each other’s actions and positions (Figure 6.18).

- Lay empty fire extinguishers on their sides after use. This signals to others that they are empty and reduces the chance of someone taking one and approaching a fire with an empty extinguisher.

Figure 6. 18 Firefighters coordinating agent application while using two fire extinguishers.