12 Chapter 11: Tactical Ventilation

Welcome! Tansi!

Essentials of Firefighting

Chapter Objectives

- Explain why tactical ventilation is performed at a structure fire. [4.3.11, 4.3.12]

- Describe safety considerations related to tactical ventilation. [4.3.11, 4.3.12]

- Describe ventilation tools and equipment. [4.3.11, 4.3.11, 4.3.12, 4.5.1]

- Describe horizontal ventilation. [4.3.11]

- Describe vertical ventilation. [4.3.12]

- Describe considerations related to the ventilation of basements and other special compartments. [4.3.11, 4.3.12]

- Skill Sheet 11-1: Perform mechanical positive pressure ventilation. [4.3.11, 4.5.1]

- Skill Sheet 11-2: Perform horizontal hydraulic ventilation. [4.3.11]

- Skill Sheet 11-3: Ventilate a flat roof. [4.3.12]

- Skill Sheet 11-4: Ventilate a pitched roof. [4.3.12]

While the term ventilation is traditionally used in the fire service, the activity is more accurately referred to as tactical ventilation. Tactical ventilation is the planned and systematic removal of heated air, smoke, gases or other airborne contaminants from a structure, replacing them with cooler and/or fresher air to meet the incident priorities of life safety, incident stabilization, and property conservation. It must be coordinated with fire suppression operations to prevent unwanted consequences for crews or victims.

Correctly implemented, tactical ventilation helps achieve the three incident priorities of life safety, incident stabilization, and property conservation. However, if ventilation is improperly applied, the results can traumatize occupants, firefighters, and the structure. The concepts presented in this chapter are based on the information found in Chapter 3, Building Construction, roof design and construction and Chapter 4, Fire Dynamics, including fire behaviour in compartments, stages of fire development, and the reaction of building construction to fire.

Now, what?

Let’s get learning!

Lesson 1

Outcomes:

- Explain why tactical ventilation is performed at a structure fire.

Reasons for Tactical Ventilation

Tactical ventilation is the planned, systematic, and coordinated removal of heated air, smoke, gases or other airborne contaminants from a structure. It is a tool to help firefighters control a fire (Figure 11.1). Tactical ventilation is also used during overhaul and loss control to evacuate smoke from structures after the fire has been extinguished.

Being in control of the fire means using ventilation and water application to control its behaviour. In terms of ventilation, firefighters control the flow of oxygen, smoke, and hot gases to then control the rate of fire growth and spread.

Tactical ventilation, either creating openings in the structure or closing/covering openings should be coordinated with an emphasis on controlling oxygen availability. As described in Chapter 4, Fire Dynamics, whenever a fire has sufficient access to oxygen and fuel, it will grow and spread.

Ventilation also allows firefighters to control where hot gases and smoke exhaust from a structure. Controlling exhaust openings may improve visibility inside the structure so that interior crews can work more effectively. Exhaust openings can also be used during overhaul to facilitate the removal of smoke or toxic gases after fire extinguishment.

Controlling Oxygen Availability

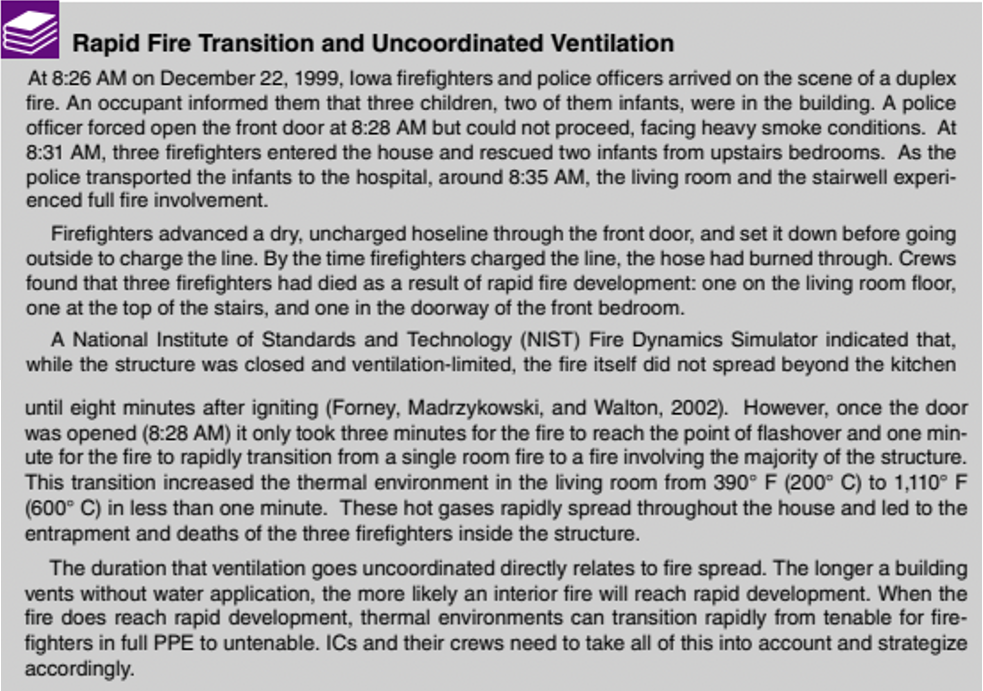

Fires contained within a compartment (room) or structure consume available fuel and oxygen as they burn. As the fuel and the oxygen burn, they undergo a chemical reaction that produces heated toxic gases, unburned hydrocarbons, and carbon particles (soot). As the oxygen inside the room or structure gets consumed, the fire burns less efficiently, and the amount of unburned fuel in the combustion products increases. If the compartment or structure does not ventilate before consuming most of the available oxygen, the fire enters a state of ventilation-limited decay. These conditions indicate an interior environment that is waiting for more oxygen to re-enter the growth stage. Any ventilation of such an environment will provide the oxygen that the fire needs which may lead to rapid fire development.

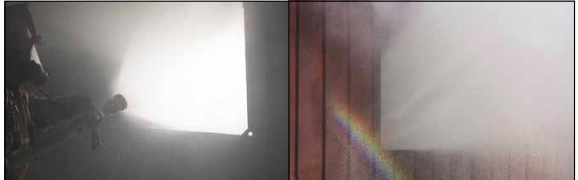

Flow Path Control

Controlling available flow paths can be as simple as keeping an exterior door closed until a charged line is in place or as complex as performing vertical ventilation. However, even with coordinated tactical ventilation, there will be an increase in the combustion rate when the fire is ventilation-limited until water is applied to cool the fire gases. To control the flow path, firefighters can be positioned at doors that the crew passes through along their entry path. Normally, this is just the entry door in residential fires. Their role would be to close any doors as much as the hoselines in use will allow. Additionally, these personnel can help pull additional hose-line deeper into the structure or shift it around, if necessary (Figure 11.2).

Ventilation and firefighting operations must be coordinated to maximize effectiveness. Personnel should receive and follow specific instructions on when and where to ventilate.

Breaking windows unnecessarily or freelancing disrupts the ventilation strategy, which in turn loses control of the fire. As heat and smoke get exhausted, the firefighting crew can move closer to the seat of the fire for extinguishment.

An effective way of controlling ventilation is to cover openings rather than creating more openings. Before interior attack, closing exterior doors and windows or using smoke control devices and/or wind control devices to cover ventilated windows will reduce the oxygen available to the fire. Closing any openings hinders fire growth until an attack can be planned and established (Figure 11.3). In general, closing openings helps control the fire unless closing those openings goes against an established incident strategy.

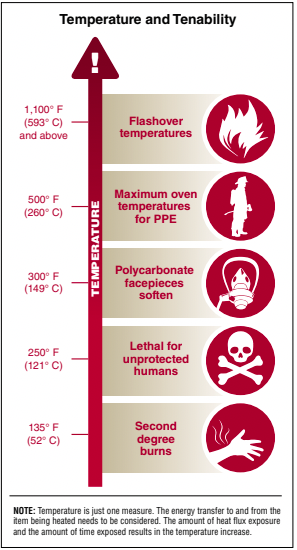

Rapid Fire Development Potential

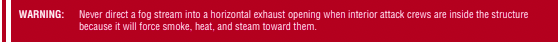

As a fire grows, it can quickly reach temperatures beyond what standard protective gear can handle, typically within a few minutes. If the existing ventilation system supports fire growth, a phenomenon called flashover can occur in less than five minutes after ignition. These conditions are extremely dangerous for both occupants and firefighters, even when wearing full protective gear (Figure 11.4).

When fresh air (oxygen) enters a room through ventilation, it can reignite heated gases, leading to rapid fire growth. In such situations, neither firefighters nor occupants can survive. To prevent rapid fire growth, it’s crucial to apply water streams properly to cool down the heated gases and to use appropriate ventilation techniques to release them. The techniques for water application are detailed in Chapter 13, “Hose Streams and Water Supply,” and Chapter 14, “Fire Suppression.”

Ventilating without proper coordination can result in flashover. Simply adding more ventilation won’t limit the fire or prevent flashover. The longer a structure or compartment ventilates without applying water, the faster flashover will happen.

Even if ventilation initially appears to cool the interior and remove smoke and toxic gases effectively, this effect is short-lived. The additional oxygen from ventilation allows the fire to grow towards flashover. To prevent flashover, ventilation and fire attack must be coordinated almost immediately, at least within the short time when ventilation alone improves conditions. Proper ventilation slows down the rate of fire spread and increases visibility, but it’s not enough on its own. Both ventilation and water application are necessary to control a fire.

Once water is applied, ventilation can further improve conditions inside the structure, allowing firefighters to conduct search-and-rescue and fire suppression operations safely. Ventilation openings should enhance conditions rather than fueling fire growth. This reduces the risk of flashover while firefighters are inside, making their tasks safer. If ventilation is intended to facilitate interior fire attack, the attack team must be prepared with charged handlines before starting tactical ventilation (Figure 11.6).

Removing Hot Gases and Smoke

Ventilation takes advantage of the buoyancy of fire gases, allowing them to escape from the

structure. During ventilation operations, gases flow from the interior to the exterior because the interior gases, heated by the fire, have become less dense (Figure 11.7). Gases less dense than air are buoyant, tend to rise, and move toward areas of lower pressure. As the less dense, higher pressure, hot gases escape, they create a lower pressure that draws in cooler ambient air down low.

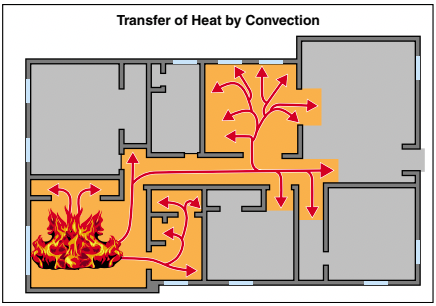

The primary mode of heat transfer from one compartment to another in a structure fire is convection (Figure 11.8). Convection — as explained in Chapter 4, Fire Dynamics — occurs because the natural buoyancy of smoke moves toxic gases and heat from one room to another. If not coordinated, the same ventilation operation that changes the flow path within the structure can move additional heat and smoke to areas not originally involved in the fire.

Because fires inside structures are almost always ventilation-limited, tactical ventilation may provide the fire with the necessary oxygen to grow, rather than creating a more tenable environment for firefighters. Tactical ventilation can be an effective strategy only if coordinated with an immediate fire attack.

Studies have shown that ventilation openings remove less heat and smoke than previously thought and alter the structure’s flow path. That introduces more air into the structure (Zevotek and Kerber 2016). This air carries sufficient oxygen to alter the fire’s natural development and intensify its growth. Even though ventilation openings introduce air, they do have to be made to allow smoke, heat, and toxic gases to escape.

Controlling the process is key and requires water application in addition to ventilation. Water application to the hot gas layers combined with tactical ventilation can minimize the effect of the new air on fire growth. Water application to the fire compartment begins to transition the fire from ventilation-limited to fuel-limited conditions. Ventilation alone will not achieve this transition.

Tactical ventilation that is implemented during or after suppression can create an interior environment or egress path with the following, more tenable conditions:

- Increased oxygen concentration

- Reduced concentration of toxic products of combustion

- Reduced temperature levels

- Increased visibility to aid in firefighting operations and primary search operations

![]()

Applications for Life Safety

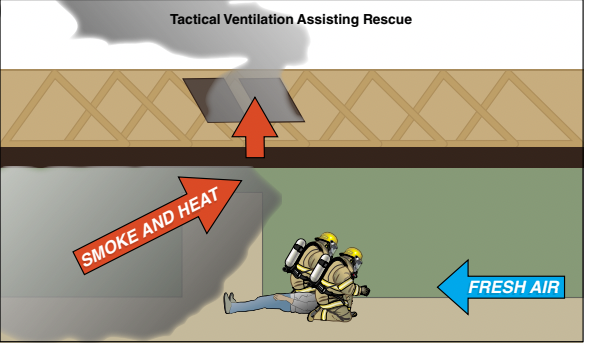

As the highest incident priority, life safety applies to occupants who may be trapped in the structure and the firefighters who must enter it to rescue them. Tactical, coordinated ventilation can be used to alter the flow path away from trapped occupants. This tactic still allows oxygen into the structure but may be necessary to create tenable egress areas for firefighters to rescue victims or trapped occupants (Figure 11.9).

Applications for Interior Operations: Interior Fire Attack and Search and Rescue

The removal of smoke and gases should create areas where firefighters can move and work inside a structure. As heat and smoke get exhausted, the firefighting crew can then move closer to the seat of the fire for extinguishment. In addition, the ventilation should be organized to prevent the fire from spreading toward searching firefighters. As a tactic for search and rescue, tactical ventilation should be delayed until lines are charged and crews are ready. Keep the fire ventilation limited as long as possible to prevent fire spread.

In terms of search and rescue, all rescue teams (entry team, exterior attack teams if needed, ventilation teams, door control monitors) should be ready to go before initiating ventilation. Ensuring that everyone’s actions are coordinated helps to control the amount of oxygen allowed into the structure. Search crews should communicate their observations to the IC and exterior crews who are coordinating ventilation so that exterior firefighters can adjust activities as needed. The goal is to complete a rescue without increasing the hazard to trapped victims, harming entry firefighters, spreading the fire to new compartments, or allowing the fire to enter rapid fire development.

Applications during Overhaul

Once the fire is suppressed, ventilation can be established to accelerate the clearing of smoke and hot gases within the structure (Figure 11.10). Clearing the structure of smoke could make the environment more tenable for victims and make it easier to find any survivors.

Ventilation can be performed as part of overhaul and property conservation. Removing smoke from buildings after fire extinguishment minimizes smoke damage to the structure.

Safety Considerations When Ventilating

Successful tactical ventilation conducted in conjunction with fire attack depends on:

- Careful planning

- Communication of scene observations to the Incident Commander (IC)

- Systematic application of procedures for removing the contaminants

- Coordination with other fireground activities

- Recognition that all openings (doors, windows, other openings) are ventilation

- Recognition of the advantages and disadvantages of environmental conditions (wind, temperature) at the scene.

Situational Awareness: Tactical Ventilation

As mentioned in Chapter 1, Introduction to the Fire Service and Firefighter Safety, communicating your observations when assigned a task is essential for your safety.

The following conditions specific to tactical ventilation should be communicated to crew members and/or a supervisor:

- Location and extent of the fire

- Changes to fire behaviour, spread, and growth, including signs of rapid fire development

- Effect that ventilation at a location will have on the fire and/or exposures

- Effectiveness of planned ventilation: desired flow and exhaust efficiency

- Locations where smoke is escaping the structure (under eaves, vented windows, around doors)

- Type of building construction

- Building’s structural integrity

- Condition of the building contents

- Indications of potential structural collapse, especially roofs and floors

- Locations of overhead power lines, solar panels, and guide wires

- Locations of two escape locations for roof crews

- Changes to the roof or floor’s structural integrity

- Coordination of fireground operations with ventilation

- Wind direction and strength

Unplanned Ventilation and Structural Integrity

Ventilation may occur before, during, or after fire suppression operations start. Some examples of unplanned ventilation include failure of windows, doors, and structural members as a result of heat/fire exposure. Unplanned ventilation can significantly influence fire behaviour in ventilation-limited fires.

Firefighters should make two assumptions about any structure fire to guide their decisions when ventilating a structure:

- The structure itself consists of lightweight construction.

- The fire in the structure is ventilation-limited.

For the purposes of this chapter, you can make the same assumptions about the ventilation tactics and information included. The tactics used to ventilate a ventilation-limited fire also work when faced with fuel-limited conditions. Tactics may change as more information is known or learned about a building’s construction.

Wind Conditions

Any opening in a building, whether part of the building design or created by the fire, allows the surrounding atmosphere to affect what is happening inside the building. Whenever possible, firefighters should use the wind to their advantage (work with the wind) during ventilation. Winds as slow as 10 mph (15 kph) can affect structure fires, potentially making them wind-driven. If winds are at these speeds or faster, firefighters are safest working with the wind at their backs. See Chapter 4, Fire Dynamics, for more information about the effects of wind and wind-driven fires.

Exposures

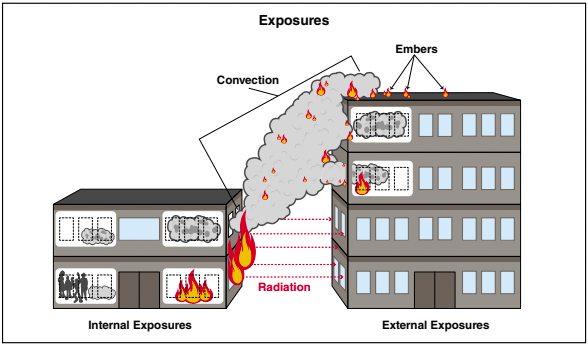

When beginning tactical ventilation operations, firefighters must consider internal and external exposures. Internal exposures include the building occupants, contents, and any uninvolved rooms or portions of the building. When ventilation does not release heat and smoke directly above the fire, some routing of the smoke becomes necessary. The routes the smoke and heated fire gases would naturally travel to exit may be the same routes occupants need for evacuation and firefighters need for working.

Ventilation that causes heat, smoke, and sometimes fire to be discharged through wall openings below the highest point of the building creates the danger that the rising gases will ignite portions of the building above the exhaust point. Heat and fire gases may be drawn into open windows or attic vents, and they may also ignite the eaves of the building or adjacent structures.

Radiation and/or direct flame contact can affect external exposures, including structures located adjacent to the fire building. Window-mounted air conditioning units or HVAC intake vents may draw smoke into adjacent buildings. Nearby structures and vegetation can be ignited if convection carries hot firebrands or embers aloft. Fire may be drawn into exterior windows or openings of the adjacent exposures (Figure 11.11).

Ventilation Location

Before selecting a place to ventilate, firefighters should gather as much information as possible about the fire, the building, and the occupancy. As a Fire Fighter I, you will be instructed on where to ventilate. It is your responsibility to communicate your observations or concerns about performing ventilation, such as changes in conditions between orders being given and actions being taken.

Roof Integrity

Prior knowledge of the roof’s construction and the building’s layout can help you gauge roof integrity. This knowledge, gained through preincident planning, can identify structural elements that may contribute to roof failure during a fire.

Examples of such structural elements can include:

- Lightweight roof trusses

- Open floor plans under wide expanses with limited truss supports

- Prior structural damage to the roof

** NOTE: Some model building codes require placarding or signage on structures to indicate the presence of lightweight construction, most notably floor and roof systems. **

If the roof is suspected to be or known to be unstable, then the IC should not place personnel on or under it. If roof ventilation is ordered, then the ventilation team should check the roof before stepping onto it and continue to check the roof ahead of their progress as they cross it.

If fire has vented through the roof or has been burning under the roof prior to fire department arrival, then roof ventilation should not be considered until after the fire has been suppressed and the roof structure can be evaluated.

Indications of possible roof collapse include (Figure 11.12):

- Melting asphalt

- Smoke coming from the roof

- Fire coming from the roof

- Building systems such as HVAC units sagging or leaning

- Spongy roof (a normally solid roof that springs back when walked upon)

- Spongy roofs will sag when pushed or walked on and spring back into shape. Spongy roofs generally indicate that the roof decking is failing.

** NOTE: Some roofs are spongy with no fire involvement. Know the roof types in your response area.**

The ventilation team should be in communication with other crews at the scene to receive updates on the progress of the fire and observed conditions. If the roof begins to lose integrity during roof ventilation operations, personnel should evacuate the roof and notify Command.

Ventilation Tools and Equipment

Firefighters use a variety of tools and equipment to perform ventilation and/or gain access to ventilation locations. Others create openings where fire gases and smoke will exit the structure. Additional tools and equipment assist in moving fire gases and smoke from a structure more efficiently.

Ground and roof ladders help firefighters access locations to be used for ventilation. The use of ground and roof ladders was covered in Chapter 8, Ground Ladders. Thermal imagers serve as useful tools for monitoring the impact of ventilation or identifying possible ventilation locations. Chapter 10, Structural Search and Rescue, for more on thermal imager use.

The following sections address:

- Tools for creating openings

- Air movement equipment

- Inspection and maintenance of ventilation equipment

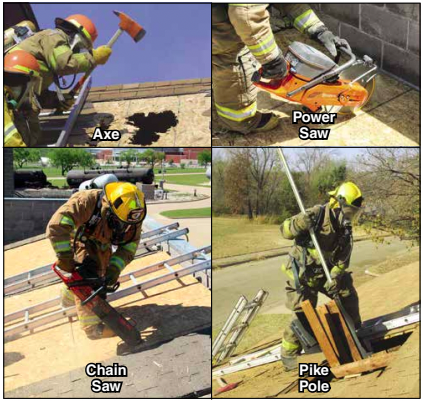

Tools for Creating Openings

Common tools for creating ventilation openings include, but may not be limited to the following (Figure 11.13):

- Axes: For breaking windows and chopping holes through roof decking

- Power saws: For cutting holes through roof decking or other obstacles

- Chain saws: For cutting holes through roof decking or other obstacles

- Pike poles: For pulling or opening ceilings

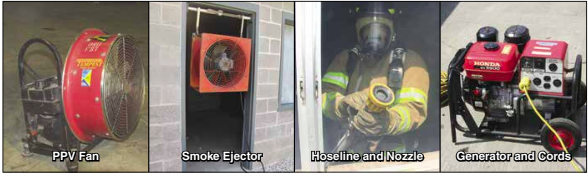

Air Movement Equipment

Common equipment used to move air through a structure or out ventilation openings include, but may not be limited to the following (Figure 11.14):

- Air movement devices: Include blowers, fans, and smoke ejectors that generate air flow

- Hoselines and nozzles: Used for hydraulic ventilation operations and resetting the fire

- Flexible ducts: Used to control the flow of fire gases and smoke during ventilation operations

- Stacking and hanging devices: Used to position air movement devices in doors and windows

- Generators and electrical power cords: Used to provide power for electrically powered air movement devices

- Wind Control Device (WCD): Heavy curtain or similar device used to cover exterior window and door openings to limit ventilation and/or prevent wind from adversely affecting ventilation conditions

- Smoke Control Device: Heavy curtain or similar device used to block interior or exterior window and door openings to limit ventilation

Inspection and Maintenance of Ventilation Equipment

Like other firefighting tools and equipment, ventilation tools and equipment should receive routine inspection and maintenance. Because maintenance of powered equipment varies, you must become familiar with the manufacturer’s maintenance instructions and follow them. As with other equipment, inspections of ventilation equipment should be well documented. Equipment that fails inspection should be marked out of service.

The AHJ should establish SOPs that outline, at least, the following items:

- Inspection and maintenance schedule

- Common items to be inspected

- Level of maintenance that firefighters provide

- When non-fire fighting personnel should perform maintenance

- Procedures for documenting inspection and maintenance

** NOTE: The inspection and maintenance of hand tools used during ventilation are described in Chapter 9, Structural Search and Rescue. **

Horizontal Ventilation

Natural, mechanical, and hydraulic ventilation are all varieties of horizontal ventilation. Natural horizontal ventilation involves opening doors and windows to allow air currents and pressure differences to remove smoke and heat from the building. Mechanical ventilation involves the use of fans and ejectors to create pressure differences. Hydraulic ventilation uses water streams to ventilate compartments and create pressure differences.

Natural Horizontal Ventilation

When conditions are appropriate, natural horizontal ventilation operations should work with atmospheric conditions, taking advantage of natural airflow. Natural ventilation requires no additional personnel or equipment to set up and maintain.

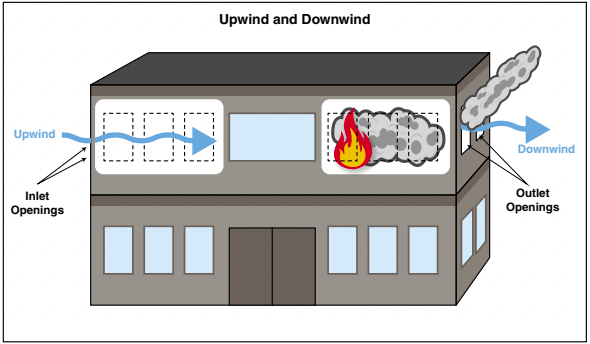

Wind Assisted Ventilation

When the IC gives the order, windows and doors on the downwind side of the structure (low-pressure side) should be opened first to create an exhaust point. Openings on the upwind side of the structure (high-pressure side) are then opened to permit fresh air to enter forcing the smoke toward the exhaust openings (Figure 11.15).

Natural Ventilation

Once the fire has been located, the IC will make decisions about how best to reach the seat of the fire and extinguish the fire. If only a single opening is made, such as opening a door, this vent will serve as the intake for air and exhaust for smoke. Opening windows or doors may allow firefighters to apply water with a straight stream from the exterior, making the fire compartment tenable for a follow-up, interior attack.

Door control is another form of natural ventilation. Doors can be used strategically in open and closed positions to change the available flow path within a structure. Firefighters should control natural ventilation as much as possible at a scene. Ventilating the structure and then walking away will allow the fire more oxygen and allow it to grow. Also, the more ventilation points added, the more oxygen the fire gets. Natural ventilation only provides a small amount of time, maybe less than a minute, for firefighters to use the improved conditions.

Natural Ventilation after Fire Suppression

Once the fire is extinguished, multiple natural ventilation openings could speed the process of removing smoke, but it could result in additional property damage. Mechanical solutions can assist with clearing the smoke quickly.

Mechanical Horizontal Ventilation Mechanical ventilation may be necessary when the natural flow of air currents and the currents that the fire creates are insufficient to remove smoke, heat, and fire gases from the structure. Mechanical ventilation is accomplished using fans, blowers, and smoke ejectors to create negative or positive pressure. Creating negative pressure means artificially lowering the pressure inside the structure so that fresh air from outside moves in more quickly. In contrast, creating positive pressure means artificially raising the pressure inside the structure so that smoke and fuel gases move toward lower-pressure openings more quickly.

Do not upset the effects of horizontal ventilation. For instance, opening a door or window on the upwind side of a burning building before creating a ventilation exhaust opening on the downwind side may pressurize the building, intensify the fire, and cause the fire to spread to uninvolved areas. Take advantage of air currents created by horizontal ventilation. If an obstruction blocks the established currents in the entry opening, the positive effects of horizontal ventilation may be reduced or eliminated.

Although mechanical methods can be applied to horizontal and vertical ventilation, it is most often used for horizontal. They may involve pulling the smoke and fire gases out through an opening or pushing fresh air into the structure and displacing the gases. Any equipment used to facilitate ventilation should be placed and awaiting coordination of other tactics. The equipment should be activated in a coordinated fashion with other activities. Air movement equipment is designed to augment the effects of natural ventilation, meaning that air will be introduced to the fire more quickly. All activities must be coordinated to ensure that using air movement equipment does not worsen fire conditions.

Mechanical Horizontal Ventilation before and during Fire Suppression

Mechanical horizontal ventilation accelerates the exchange of fresh air into a structure filled with smoke and hot gases. If the fire is not under control, this accelerated exchange of gases can do more harm than good. Mechanical horizontal ventilation will add air to the structure more quickly than natural ventilation. If this tactic is used to create visibility and a flow path for interior operations, then all equipment must be in place; all crews must be coordinated and ready before opening intake and exhaust locations and starting the air movement devices.

Some of the limitations of mechanical ventilation include the following:

- Depends upon a power source

- Requires special equipment

- Requires more resources and personnel than natural ventilation

Mechanical Horizontal Ventilation Uses after Fire Suppression

Even in the absence of fire, contaminated atmospheres must be cleared quickly and thoroughly from a building or other confined space. For example, buildings filled with flammable or toxic gas must be ventilated quickly but safely. Confined spaces containing low oxygen levels can benefit from the introduction of fresh air as the contaminated products are removed. Clearing contaminated structures of smoke reduces smoke damage and improves relations with home or business owners. In these and many other situations, mechanical ventilation is the most effective technique to use.

Exhaust from gas-powered fans can add carbon monoxide to a structure during overhaul. Firefighters should continue to wear SCBA and monitor the environment until there is confirmation that the atmosphere is safe (Figure 11.16). Ventilation after fire suppression should lower carbon monoxide (CO) levels. If it does not, gas-powered fans may be the reason. For more information on procedures during overhaul and loss control, see Chapter 15, Loss Control.

Some of the advantages of using mechanical ventilation to clear contaminated atmospheres are:

- Supplements and enhances natural ventilation

- Ensures more control of air flow

- Speeds the removal of contaminants

- Reduces smoke damage

- Promotes good public relations

Negative-Pressure Ventilation

Negative-pressure ventilation (NPV) is the oldest type of mechanical ventilation. Air movement equipment is used to develop artificial airflow to pull smoke from the structure or to enhance natural ventilation. The negative pressure created draws smoke and hot fuel gases out of the structure and draws fresh air into the structure. Fans can be placed in windows, doors, or roof vent openings to exhaust the smoke, heat, and gases from inside the building to the exterior (Figure 11.17). NPV requires electricity, generally supplied by a cord run from a generator to the fan. NPV also requires that the opening around the fan be sealed to prevent outside air from being drawn in around the fan. NPV is not as effective as other ventilation options for removing smoke.

Safety guidelines for using smoke ejectors are as follows:

- Keep the intake side of the ejector free from obstructions, such as debris, curtains, or drapes.

- Turn off smoke ejectors when moving them.

- Carry smoke ejectors using the handles provided for that purpose.

- Ensure that people, clothing, curtains, or draperies that are near to or could be drawn into the blades before starting a smoke ejector are secured or removed.

- Avoid standing in the outlet area of the smoke ejector; the discharged air may contain flying debris.

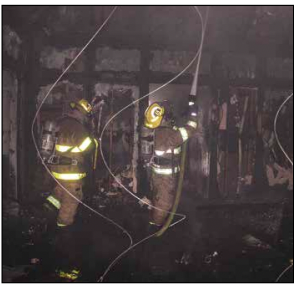

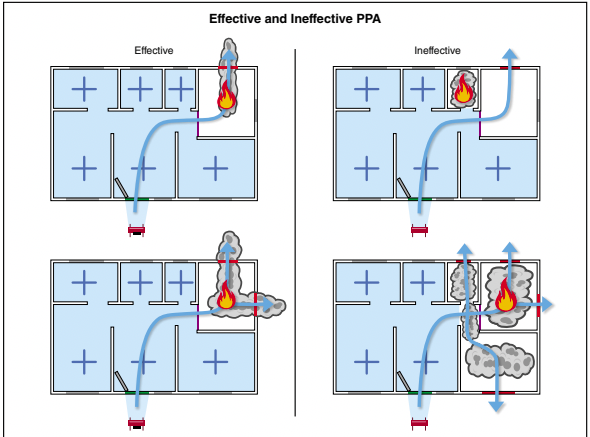

Positive-Pressure Attack

Positive-pressure fans are most effective in containing fires within a compartment. The goal is to use high-volume fans to create slightly higher pressure in nearby compartments, pushing smoke outside through exhaust openings. However, as a fire grows, it naturally creates pressure, challenging the effectiveness of this tactic. To work well, the fan must create enough pressure to push smoke and heat toward the desired exhaust openings. Otherwise, smoke may flow towards the fan’s intake. This tactic, known as positive-pressure attack (PPA), helps reduce heat exposure for firefighters during interior operations when executed properly. Incorrect application of PPA can lead to rapid fire development and spread.

The fan is set up at the intake, where airflow is introduced, while exhaust openings allow combustion products to exit the structure (Figure 11.18). Fans vary in size and type between departments, so firefighters should be familiar with their department’s equipment and follow manufacturer recommendations and department procedures for fan placement.

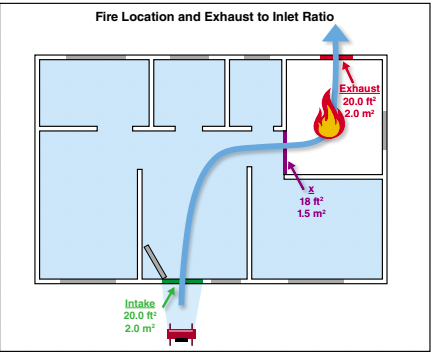

Two main factors for PPA are the fire location and the exhaust-to-intake size ratio. This ratio compares the surface area of exhaust openings with compartment intake openings. PPA works best when the fire’s location is known, and the exhaust-to-intake ratio is greater than 1 to 1. Proper placement of exhaust openings, primarily in the fire compartment, ensures efficient smoke and heat removal. Additional exhaust openings away from the fire compartment can disrupt airflow and weaken the fan’s effectiveness.

Controlling pressure is crucial. The fan and the fire both generate pressure, and uncontrolled pressure can alter airflow unpredictably. Firefighters must either control the fan’s pressure or apply water to cool the fire. Larger exhaust openings than intakes maintain lower pressure in the fire compartment, controlling fire and airflow paths.

Coordination between crews is vital during PPA. Changes to airflow may trigger rapid fire development, potentially trapping crews inside. Crews must enter and exit through intakes and avoid blocking them. Inside, crews should only search open compartments to avoid altering airflow paths unintentionally.

The application of water to the fire compartment will reduce the pressure differences that the fire creates, making PPA more effective. The decreased temperatures along the path of approach allows this to happen faster. Although temperatures are reduced while approaching the fire compartment, crews should apply water to the fire compartment as soon as streams will reach. Water improves the effectiveness of the PPA as soon it enters the compartment.

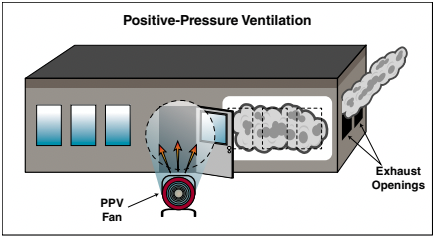

Positive-Pressure Ventilation

The same high-volume fans used in positive-pressure attack (PPA) can also be employed to remove smoke, heat, and toxic gases from the structure after fire suppression. This tactic is called positive-pressure ventilation (PPV). PPV speeds up the natural ventilation process of the building. When the pressure inside the building is higher than outside, smoke moves towards selected lower-pressure exhaust points. Unlike PPA, PPV doesn’t focus much on the exhaust-to-intake ratio. The goal of PPV is to increase pressure higher than outside the structure, not higher than what the fire can produce. This allows formore exhaust openings, increasing airflow and helping the interior environment return to normal conditions faster (Figure 11.21).

Starting PPV soon after fire suppression improves ventilation effectiveness. The fan reduces temperatures, decreases toxic gas concentration, and improves visibility, making interior operations like search and rescue safer and more efficient.

However, while PPV speeds up ventilation, it can also conceal fire extension while fans are running. Smouldering fires may intensify with increased airflow. It’s crucial to identify and control fire extension when using PPV. Once interior conditions improve, briefly shutting off the fan or closing the intake allows crews to assess smoke conditions and identify potential extensions before they become larger hazards.

To ensure effective PPV:

- Ensure exhaust surface area exceeds intake area.

- Monitor PPV fan operation.

- Maintain communication between Incident Command, interior attack crews, and PPV operator.

- Take advantage of wind conditions.

Advantages of PPV over natural pressure ventilation (NPV) include:

- Setting up PPV blowers without entering a smoke-filled environment.

- Equally effective with horizontal or vertical ventilation.

- More efficient removal of smoke and heat.

- Pressurizing exposed buildings or adjacent compartments to reduce fire spread.

- Disadvantages of PPV include:

- The structure must have some remaining compartmentation.

- Exhaust from gas-powered fans may introduce carbon monoxide.

- Hidden fires may accelerate and spread throughout the building.

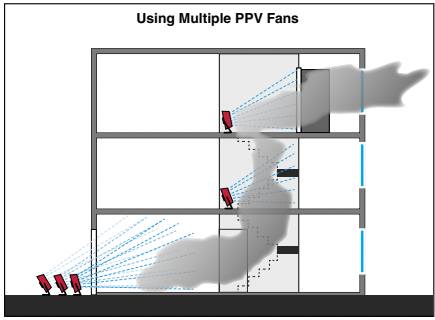

In commercial and multi-story buildings, it’s best to apply positive pressure at the lowest point, usually ground level. Opening and closing doors until the building is free of smoke directs positive pressure throughout. If one fan isn’t enough, additional fans can be set up on upper floors and at entry points to increase airflow. Exit points can then be opened to remove smoke one floor at a time, starting with the most heavily smoke-charged floor. Larger blowers may be used in multistory and large-volume buildings.

The main problem in using PPV in aboveground operations is coordinating the opening and closing of the

doors in the stairwell used to ventilate the building. To control openings or pressure leaks, one person is placed in charge of the pressurizing process. It helps to use portable radios and have firefighters patrol stairwells and hallways.

Hydraulic Ventilation

Hydraulic ventilation:

- May be used in situations where other types of forced ventilation are unavailable.

- Can be used to clear a room or building of smoke, heat, steam, and gases after a fire has been controlled.

- Uses a spray stream from a fog nozzle to entrain smoke and gases and carry them out of the structure through a door or window.

- Requires firefighters to operate the nozzle within the contaminated atmosphere.

To perform hydraulic ventilation, set a fog nozzle on a pattern wide enough to cover the exhaust opening

through which the smoke will be drawn or pulled (Figure 11.23). The farther you get from an exhaust opening, the more air entrains into the fog pattern. The more air entrained, the more heated gases get ventilated from the room. The larger the opening, the faster ventilation will occur.

Horizontal hydraulic ventilation procedure is shown in Skill Sheet 11-2.

Hydraulic ventilation has its disadvantages including the following:

- If done incorrectly, water damage may increase within the structure.

- Depletes the water supply, a more common problem during rural firefighting operations where water shuttles are being used.

- More ice will form on the ground surrounding the building when temperatures are below freezing.

- The firefighters operating the nozzle must remain in the heated, hazardous atmosphere throughout the operation.

Vertical Ventilation

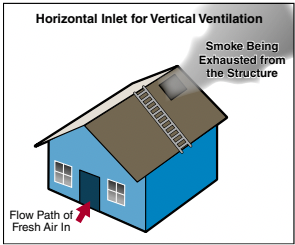

Vertical ventilation involves creating openings in a roof or using existing openings to channel smoke, hot gases, and products of combustion out of the structure. Cutting a hole in the roof above the fire or opening existing roof access doors, scuttles, or skylights are all examples of vertical ventilation. For vertical ventilation to be effective, a horizontal inlet opening at or below the level of the fire is needed to provide a flow path for fresh air to enter the structure (Figure 11.24).

Requirements for Successful Vertical Ventilation

Vertical ventilation presents the following increased risks:

- Placing personnel above ground level

- Working on both peaked and flat surfaces

- Working above the fire

- Working on roofs that may have been weakened because of age or fire damage

Trained firefighters who conduct a well-coordinated attack can avoid ventilation problems. Some common factors that can reduce the effectiveness of vertical ventilation are:

- Improper use of mechanical ventilation

- Uncoordinated ventilation

- Fog streams directed into ventilation openings

- Burn-through of the roof, floor, or walls

- Additional openings between the attack team and the upper opening

- Improper location of the vertical ventilation opening

Vertical ventilation is often impractical or impossible. In these cases, other strategies, such as the use of strictly horizontal ventilation, must be employed.

Some of the safety precautions that should be observed include the following:

- Work with the wind at your back or side when cutting a roof opening to protect yourself from heat, smoke, and embers.

- Ensure that main structural supports do not get cut when creating a ventilation opening.

- Guard the ventilation opening to prevent personnel from falling into it.

- Evacuate the roof promptly when ventilation work is complete or when ordered to leave.

- Use lifelines, roof ladders, or other means to prevent personnel from sliding and falling off the roof.

- Make sure that a roof ladder (if used) is firmly secured over the peak of the roof before working from it.

- Exercise caution when working around electric wires, solar panels, and guide wires.

-

Figure 11.27 Firefighters should sound the roof before stepping onto it. Ensure that all personnel on the roof are wearing full PPE, including SCBA, and that they are wearing their masks and breathing SCBA air.

- Stay out of range of those who are swinging axes and operating power saws.

- Remain aware of overhead obstructions within the range of your swing.

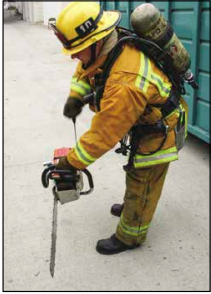

- Start power tools on the ground to ensure operation but make sure they are shut off before hoisting or carrying them to the roof (Figure 11.25).

- When using a power saw, make sure that the angle of the cut is away from the body.

- Extend ground ladders at least three rungs above the edge of the roof or top of the parapet wall, and secure the ladder to the wall or roof.

- When operating from aerial ladder platforms, the floor of the platform should be even with or slightly above roof level (Figure 11.26).

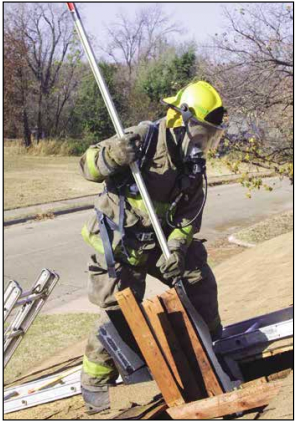

- Check the roof for structural integrity before stepping onto it, and use all available methods to continue to monitor the roof’s structural integrity throughout the operation (Figure 11.27).

- Before and after ventilating, walk along load-bearing walls and the strongest points of the roof structure when-ever possible.

- When the roof has been opened, penetrate the ceiling below to enhance ventilation (Figure 11.28).

Before stepping off a ladder, parapet wall, or another place of safety onto the roof of a burning building — especially if smoke or darkness obscures the roof — firefighters should strike the roof surface with the blunt end of a pike pole, rubbish hook, or axe. When a tool strikes a roof, roofs with intact sheathing will feel solid, and the tool will tend to bounce off the surface. Striking the roof will only determine if its sheathing is intact.

Sounding

Sounding (striking the surface of a roof to determine its structural integrity) provides no information about the structural members beneath the sheathing. Buildings with lightweight construction may have roof trusses that fail under fire before the roof sheathing. When this occurs, the sheathing may sound solid but will fail under your weight.

Remember, however, that roofs with several layers of composition shingles or other roof coverings may not respond to sounding. They may sound solid when struck with a tool even though the fire may have severely damaged the roof supports. Also, roofs covered with tile or slate cannot be sounded; the tiles/slates must be removed to reveal the underlying structure.

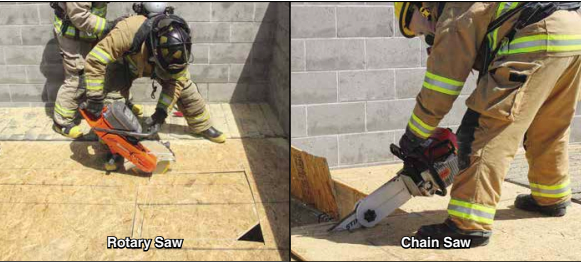

Rotary saws, carbide-tipped chain saws, and chain saws with adapted features are excellent for roof-cutting operations (Figure 11.29). They are faster and less damaging than axes and other manual cutting tools. The saw operator must have good footing and always maintain control of the saw. Working on a pitched roof from a roof ladder, an axe, a rubbish hook, or Halligan can be used to provide a secure foothold for the saw operator. In most cases, it is safest to turn off the saw when it is being transported to or from the point of operation — especially when climbing or descending a ladder.

The roof ventilation team should be in constant communication with their supervisor or the IC. The teams should maintain situational awareness and report changes they see to the supervisor.

Responsibilities of the roof ventilation team leader include:

- Ensuring that the roof is safe to stand/walk on (sounding, visual observation)

- Ensuring that only the required openings are made

- Directing efforts to minimize secondary damage (damage that fire fighting operations cause)

- Coordinating the team’s efforts with those of firefighters inside the building

- Ensuring the safety of all personnel who are assisting with ventilation operations

- Ensuring that there are two means of egress from the roof

- Ensuring an adequate exhaust opening size

- Ensuring that the team leaves the roof as soon as their assignment is completed

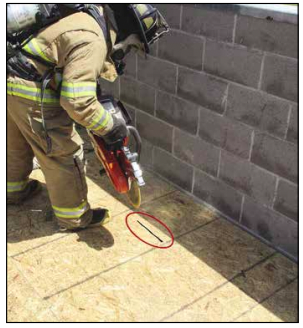

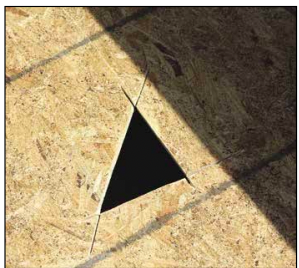

Before cutting any type of ventilation hole, you should cut an inspection hole in the roof. Inspection holes help to determine the location of a fire, the presence of fire below the roof, and construction features of the roof. Comparing observations from multiple inspection holes can provide information about fire spread. Inspection holes are used in offensive and defensive ventilation operations. There are two primary types of inspection holes: the kerf cut and the triangle cut.

The kerf cut is the easiest and fastest inspection hole to cut. Make a single cut in the roof surface using a rotary saw, chain saw, or axe. The resulting hole should be the width of the saw or axe blade (Figure 11.30). The only information a kerf cut provides is whether smoke or flame is escaping from the cut. It is usually not wide enough to see through, so it does not allow for visual inspection. The presence of smoke will provide some indication of conditions below the roof. If flames come through the kerf cut, leave the area and do not proceed with the ventilation cuts.

The triangle cut may provide a better view of conditions beneath the roof. Using a power saw, the cut can be created from a single kerf cut if conditions indicate a need for it. The triangle cut consists of three overlapping cuts that form a triangle (Figure 11.31). If fire is present, report the information to the IC and suspend ventilation. Remember that heated smoke, gases, and sometimes fire will exit the inspection hole.