6 Chapter 5: Firefighter Personal Equipment

Introduction

Welcome! Tansi!

Essentials of Firefighting

Course Objectives

- Describe the various types and uses of personal protective equipment (PPE) worn by firefighters. [4.1.1, 4.3.2, 4.3.3]

- Describe the inspection, cleaning, and maintenance of PPE. [4.1.2]

- Describe conditions that require the use of respiratory protection equipment. [4.3.1]

- Identify SCBA components. [4.3.1]

- Describe SCBA limitations. [4.3.1]

- Describe the procedures for donning and doffing SCBA. [4.3.1]

- Explain the process of inspecting and cleaning SCBA. [4.5.1]

- Describe methods of refilling, replacing, and storing SCBA cylinders. [4.3.1, 4.5.1]

- Describe safety considerations for working in and exiting a hazardous atmosphere while wearing SCBA. [4.3.1]

Firefighters and emergency responders work in a wide variety of hazardous environments. To protect your life and health, you must wear the proper safety equipment correctly at all times. This chapter provides an overview of two types of safety equipment: personal protective equipment (PPE) and respiratory protection. You will learn about the different types of this equipment, their functions, proper usage, and maintenance.

Now, what?

Let’s get learning!

Lesson 1

Outcomes:

- Explain the basic principles of fire science.

Personal Protective Equipment (PPE)

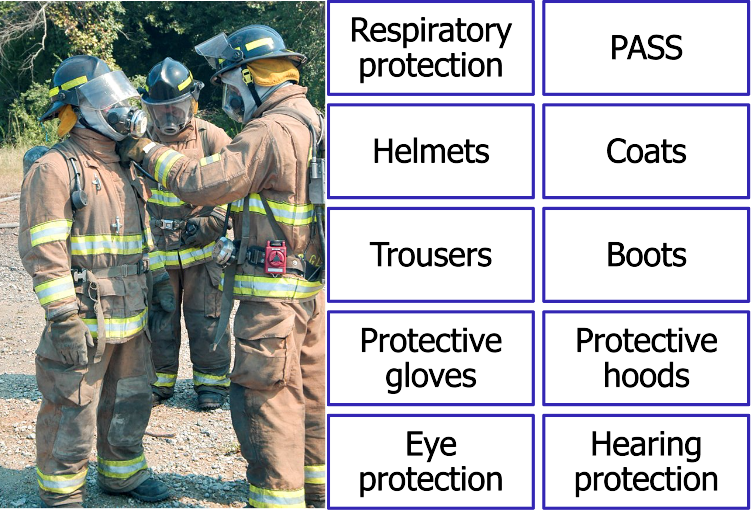

Firefighters should wear personal protective equipment (PPE) that is appropriate for the type of incident and activity being performed. Properly wear all PPE with all closures fastened, SCBA facepiece in place, and air cylinders activated before entering the structure. Your helmet’s face shield, if so equipped, can provide a secondary layer of eye protection. Your supervisor, incident safety officer, or another firefighter should perform a quick inspection to make sure your PPE is properly donned and operational before you enter the structure (Figure 5.1).

A quick inspection of each firefighter’s PPE should be made before they enter a hazardous environment.

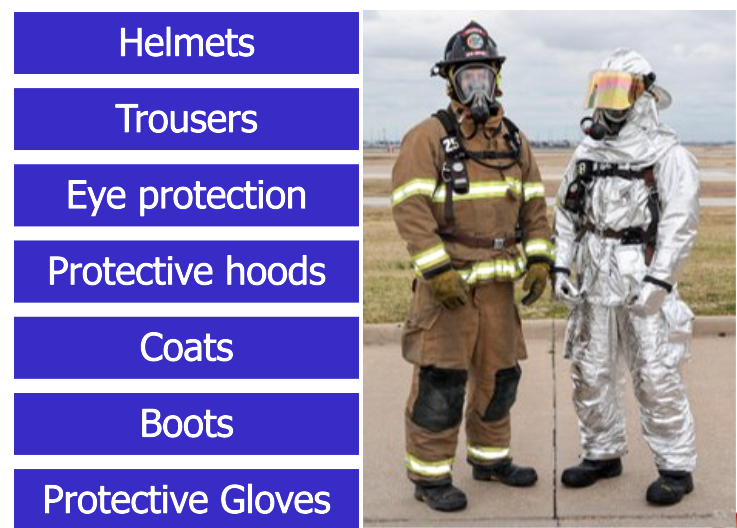

PPE is designed to protect you from hazards and minimize the risk of injury or fatality. PPE usually consists of the following:

- Respiratory protection equipment

- Personal alert safety system (PASS)

- Helmets, coats, trousers, boots, protective gloves, and protective hoods

- Eye protection

- Hearing protection

Some emergency situations require full sets of PPE, including respiratory protection, while others require only protective clothing. Types of PPE include:

- Station and work uniforms

- Structural firefighters’ protective clothing

- Wildland fire fighting protective clothing

- Roadway operations protective clothing

- Emergency medical protective clothing

- Special protective clothing such as chemical protective clothing

**NOTE:Emergency medical protective clothing and special protective clothing are beyond the scope of this chapter. You will likely learn about emergency medical protective clothing when you are trained to your AHJ’s level of emergency medical services training. Special protective clothing is taught during hazardous materials awareness and operations training.**

Station and Work Uniforms

Station and work uniforms perform two basic functions. First, they identify the wearer as a member of the organization. Second, they provide a layer of protection against direct flame contact (Figure 5.2).

Firefighters should not wear clothing made of non-fire-resistant synthetic materials while on duty or under PPE because these materials can melt when heated and stick to the skin, causing serious burns.

Types of non-fire-resistant synthetic materials include:

- Nylon

- Iron-on patches

- Polyester

- Transfer decals

**NOTE:Refer to department policies concerning what can and cannot be worn while on duty or under PPE.**

All station and work uniforms should meet NFPA 1975 requirements. This standard provides the minimum requirements for work wear that is functional, will not contribute to firefighter injury, and will not reduce the effectiveness of outer PPE. Garments addressed in this standard include trousers, shirts, jackets, and coveralls, but not underwear. Underwear made of 100 percent cotton is recommended.

NFPA-1975-compliant garments have a permanently attached label stating their compliance certification. While this clothing is designed for fire resistance, it is not designed for firefighting operations. You must always wear structural firefighting protective clothing over these garments during structural firefighting activities. Depending on their design and local protocols, you may wear wildland protective clothing over station and work uniforms or directly over undergarments. Some station and work uniforms are dual certified as both work uniforms and wildland protective clothing. Dual-certified uniforms will always carry the appropriate certification labels.

Safety shoes or boots are part of the station and work uniform. They are required footwear when working around the station. Safety shoes or boots usually have steel toes, puncture-resistant soles, or special inserts. Do not wear station footwear during emergency operations because they might contaminate living quarters with potentially hazardous substances when you return to the station. Any emergency response can soil or contaminate uniforms. Therefore, you should not take uniforms home or wash them in personal washing machines or at public laundromats. Contaminated uniforms must be laundered at the fire station or by a contractor.

Structural Fire Fighting

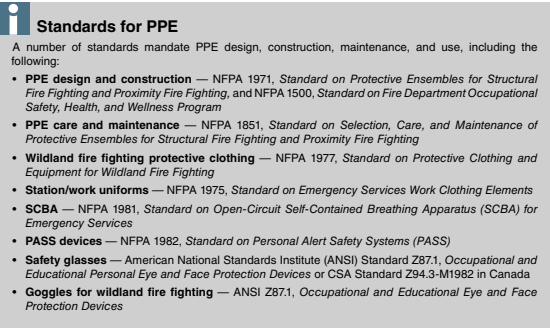

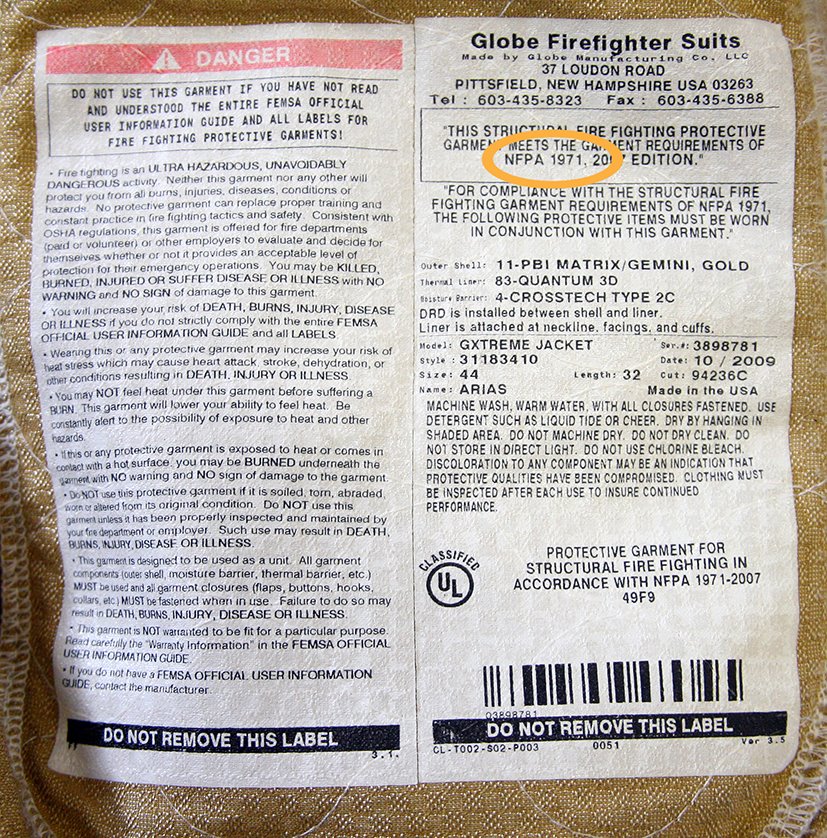

PPE All PPE designed for structural and proximity firefighting must meet the requirements of NFPA 1971 (Figure 5.3). This standard addresses the requirements for:

![]()

Key Takeaways

Uniform:

- Should meet NFPA 1975 requirements and have compliance label attached

- Designed for fire resistance, but not fire fighting operations

- May be worn under structural or wildland PPE

- Some are dual certified as work uniforms and wildland protective clothing

Shoes:

- Required at the station

- Usually have steel toes, puncture-resistant soles, or special inserts

- Do not wear during emergency operations

Contamination:

- Do not take home uniforms

- Do not launder uniforms in personal or public machines

- Uniforms must be laundered at the station or by a contractor

Labels must include the following information:

- Manufacturer’s name, identification, or designation

- Country of manufacture

- Month and year of manufacture

- Size or size range

- Footwear size and width (where applicable)

- Manufacturer’s address

- Manufacturer’s lot or serial number

- Model name, number, or design

- Principal materials of construction

- Cleaning precautions

PPE components must be compatible with each other to provide the level of protection intended by the NFPA standard. Each component is designed to protect you from specific hazards and may not protect you from other hazard types. For instance, structural PPE offers no protection against many types of hazardous materials.

Firefighters should never alter their protective clothing. Changing, adding, or removing components may endanger your life, void the manufacturer’s warranty, and/or affect your workers’ compensation benefits.

Alterations include:

- Removing the moisture barrier or liner of coats and trousers

- Sewing hooks, loops, or clasps to the outer shell

- Adding combustible decals to the helmet.

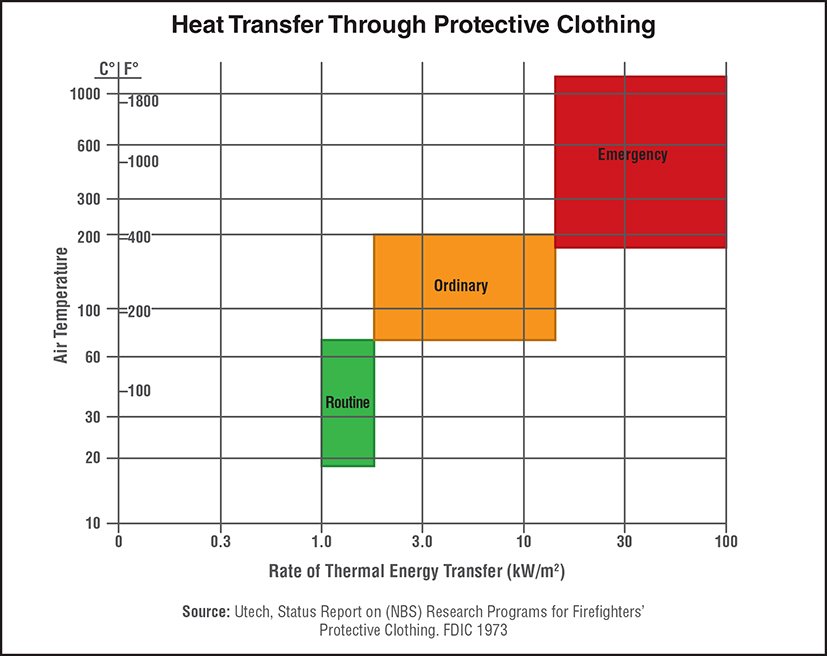

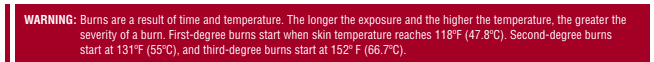

Structural PPE is designed to cover all portions of your skin when you are reaching, bending, or moving. It is also designed to prevent heat transfer from the fire to your body. During heat exposure, the clothing absorbs the heat, which prevents transfer to the skin, but there are limits to how much heat the structural protective clothing can absorb. When the gear reaches its limits, the clothing will become hot enough to cause contact burns when trapped heat permeates the firefighter’s underclothing or the firefighter’s bare skin touches the material. The usual temperature limit is somewhere above 400° F (200° degrees C). The time until the protective clothing reaches a dangerous absorption limit varies based on the heat transfer rate. The lower the heat transfer rate, the longer the protective clothing will protect you and stay within tolerable limits.

Structural PPE is designed to cover all portions of your skin when you are reaching, bending, or moving. It is also designed to prevent heat transfer from the fire to your body. During heat exposure, the clothing absorbs the heat, which prevents transfer to the skin, but there are limits to how much heat the structural protective clothing can absorb. When the gear reaches its limits, the clothing will become hot enough to cause contact burns when trapped heat permeates the firefighter’s underclothing or the firefighter’s bare skin touches the material. The usual temperature limit is somewhere above 400° F (200° degrees C). The time until the protective clothing reaches a dangerous absorption limit varies based on the heat transfer rate. The lower the heat transfer rate, the longer the protective clothing will protect you and stay within tolerable limits.

Key Takeaways

| Heat Transfer from PPE to the Body | PPE Prevents Heat Transfer Away from the Body |

|

|

Since protective clothing absorbs and stores heat, it can take longer than expected to cool. Simply leaving a hot environment for a short period of time may not be long enough to cool the clothing to safe levels for re-entry into a fire environment. You may experience contact burns or heat stress even after leaving a heated environment if you do not follow rehab protocols that allow enough time for the clothing to cool.

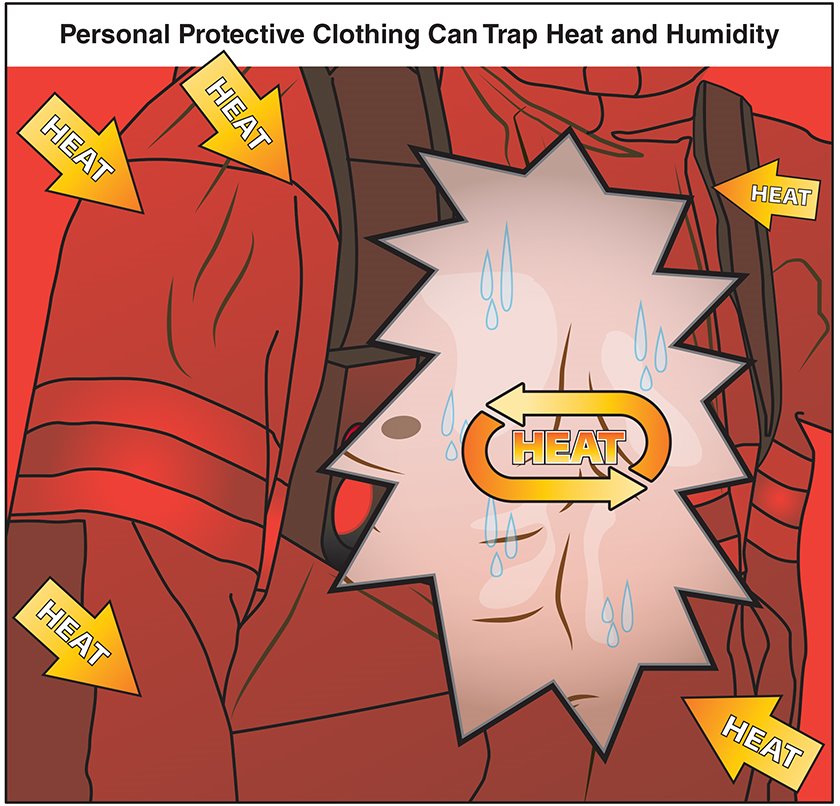

Protective clothing also prevents heat from being transferred away from your body. Usually, your body sweats to cool itself, but the protective clothing traps body heat and moisture inside the clothing barriers.

This may significantly increase the following conditions (Figure 5.5):

- Breathing and heart rate

- Core temperature

- Skin temperature

- Physiological stress

If environmental conditions allow, open your protective clothing to permit airflow around your body during authorized breaks or trips to rehabilitation facilities. This will lessen heat stress and reduce your heart rate.

Helmets

They are designed to provide multiple benefits during structural firefighting operations.

This includes:

- Preventing heated or scalding water and embers from reaching the ears and neck

- Protecting the head from impact injuries caused by objects or falls

- Protecting from heat and cold

Helmets can also help identify personnel. Shell colour indicates the firefighter’s rank; markings indicate the unit; and removable identification labels indicate accountability. All these uses are based on a department’s standard operating procedures (SOPs) (Figure 5.7).

To ensure proper protection, you must wear your helmet correctly:

- Place the helmet on your head

- Secure the chin strap under your chin and tighten it

- Fold the ear flaps down to cover your ears and neck.

- If there is a ratchet adjuster on the back of the headband, adjust it accordingly.

**NOTE:You must fold the ear flaps down even if you are wearing a protective hood. **

Eye Protection

Eye injuries are some of the most common injuries at emergency incidents, but they are not always reported because they are not always debilitating. Although eye injuries can be serious, they are easy to prevent.

Eye protection comes in many forms including (Figure 5.8):

- SCBA facepieces

- Helmet-mounted face shields

- Goggles

- Safety glasses

Helmets must come equipped with face shields or goggles. Keep in mind, however, that face shields alone do not provide adequate protection from flying particles or splashes and should be used in combination with a primary form of eye protection.

NFPA 1500, Standard on Fire Department Occupational Safety and Health Program, requires that goggles or other appropriate primary eye protection be worn when participating in operations where protection from flying particles or chemical splashes is necessary. During firefighting operations, your primary eye protection is your SCBA facepiece.

In other situations, you will need eye protection when respiratory protection is not required. Some of these situations include:

- Emergency medical responses where exposure to body fluids is possible

- Vehicle extrication operations

- Industrial occupancy inspections

- Station maintenance

These situations call for safety glasses or goggles, which protect against most eye hazards. Several styles are available, including some that fit over prescription glasses. Prescription safety glasses are another option, although these must have frames and lenses that meet ANSI or Canadian Standards Association (CSA) standards for safety glasses. In fire department facilities and maintenance areas, you should be aware of warning signs posted near power equipment requiring the use of eye protection. Always follow your department’s safety policies and procedures regarding appropriate eye protection.

![]()

Protective Hoods

Protective hoods are fire-resistant fabric coverings that protect your ears, neck, and face from exposure to heat, embers, and debris.

Hoods cover areas that may not be protected by the SCBA, such as:

- Facepiece

- Ear flaps

- Helmet

- Coat collar

The protective hood’s face opening has an elastic edge that fits tightly to the SCBA facepiece, forming a seal. Hoods are available with long or short skirts and are designed to fit inside the protective coat, forming a continuous layer of protection (Figure 5.9).

Pull the hood on before the protective coat to help keep the hood’s skirt under the coat. To ensure a secure seal between the hood and the SCBA facepiece, secure the facepiece first before pulling up the hood. This way you will not compromise the facepiece-to-face seal.

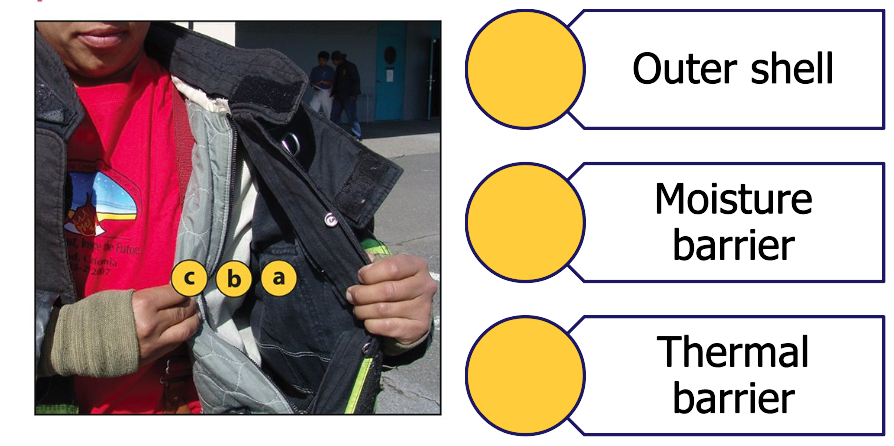

NFPA 1971 requires that all structural firefighting protective coats be made of three components (Figure 5.10).

These barriers absorb heat and trap insulating air that prevents heat transfer from the fire to your body.

Removing the liner and wearing only the shell compromises the design of the coat, increasing the likelihood of injuries or death.

Protective barriers also provide limited protection from:

- Direct flame contact

- Hot water

- Steam

- Cold temperatures

- Other environmental hazards

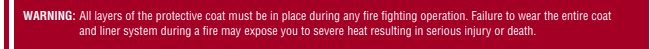

Protective coats have many design features that provide protection and convenience. Design features required by NFPA 1971 include (Figure 5.11):

- Retroreflective trim: Strips of reflective trim on the torso and sleeves that make the coat more visible at night or in low-light conditions.

- Wristlets: Fabric interface between a sleeve’s end and a firefighter’s palm that protects the wrist from water, embers, and other debris. Keeps coat sleeves from riding up when reaching.

- Collar: Protects the neck from water, embers, and other debris. The collar must be turned up under the helmet ear flap.

- Closure system: Snaps, clips, zippers, or Velcro® fasteners that secure the coat’s front. • Drag Rescue Device (DRD) — Harness and hand loop at the back of the neck that enables a rescuer to grab and drag a downed firefighter.

Coats typically contain reinforcement in high compression areas, such as the shoulders, and areas prone to wear, such as the elbows. Optional design features such as cargo, radio, or SCBA facepiece pockets are also common, which must be attached by the manufacturer to meet the NFPA standard.

Protective Trousers

Protective trousers are constructed from the same fabric, moisture barrier, and thermal layering used in protective coats (Figure 5.12). Much like the coats, high compression areas and areas prone to wear contain reinforcement, and cargo or patch pockets may be attached for carrying gloves and small tools. Heavy-duty suspenders hold up the trousers. Closure systems are the same as those found on the protective coat. NFPA 1971 also requires retroreflective trim on protective trousers.

Protective trousers

- The same materials and closure systems as protective coats

- Reinforcement in high compression areas

- Cargo or patch pockets

- Heavy-duty suspenders

- Retroreflective trim

Protective Gloves

Protective gloves protect hands and wrists from heat, steam, or cold penetration, and resist cuts, punctures, and liquid absorption. Gloves must allow enough dexterity and tactile feel for you to perform your job effectively.

For instance, gloves must permit you to grasp tools and nozzles or manipulate small objects such as control knobs on portable radios (Figure 5.13). Properly worn, the gloves cover the wristlet of the protective coat to form a complete seal. Gloves worn for structural firefighting must be NFPA-compliant for this type of activity.

Protective gloves:

- Protect from heat, steam, or cold penetration

- Resist cuts, punctures, and liquid absorption

- Must allow dexterity, feeling, and grasping

- Cover the wristlets to form a complete seal

- Must be NFPA-compliant

Protective Footwear

Firefighting boots are available in a variety of styles and materials and should meet the requirements of NFPA 1971 (Figure 5.14).

They protect the foot, ankle, and lower leg from:

- Puncture wounds to the sole caused by nails, broken glass, and other sharp objects

- Crushing wounds to the toes and instep

- Scalding water or contaminated liquids

- Burns from embers and debris

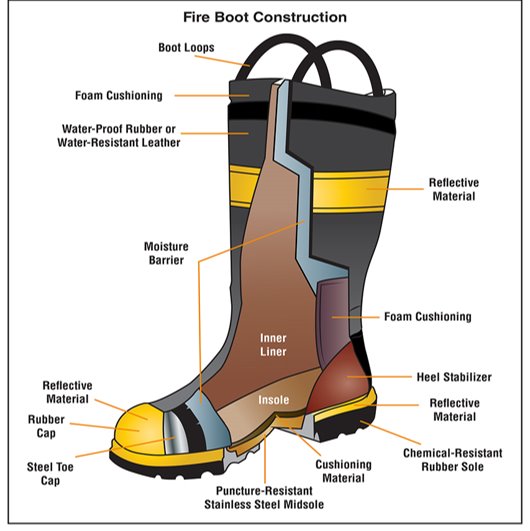

Boot Construction

- Firefighting boots have a steel inner sole and a steel or reinforced toe cap and must be high enough to protect the lower leg.

- The outer shell may be made of rubber, leather, or other water-resistant material.

- Thermal, physical, and moisture barriers are required inside the shell (Figure 5.15).

- Boot tops fit inside the trouser legs, providing a complete barrier even when you kneel.

Personal Alert Safety Systems (PASS)

Personal alert safety systems (PASS) emit a loud alarm to alert other personnel that a firefighter is in danger. The alarm activates when a firefighter is motionless for more than 30 seconds, or when a firefighter presses the emergency button. In some models, the system may activate when the temperature exceeds a preset limit. The alarm must be at least 95 decibels (dBA) and must go off continuously for at least one hour.

PASS devices assist rescuers in trying to locate trapped, unconscious, or incapacitated firefighters.

They are useful in:

- Total darkness

- Dense smoke

- Confined spaces

Some devices are stand-alone, manually activated units. Other devices are integrated units connected to the SCBA regulator that activate automatically when the main air supply valve is opened. SCBA-mounted devices can also be activated manually, without opening the cylinder valve (Figure 5.16).

PASS devices have at least three settings: off, alarm, and sensing. They also have a pre-alarm mode that activates if you are motionless for 30 seconds. This pre-alarm tone is different from the full alarm tone and is intended to prevent false alarms.

You must learn how to turn the unit from off to sensing (on) and to manually activate the alarm. You are also responsible for testing, maintaining, and activating your PASS device according to your department’s SOPs, manufacturer’s instructions, NFPA 1500, and NFPA 1982.

Key Takeaways

PASS

Alarm

- Emitted to alert personnel that firefighter is in danger

- Activates when firefighter is motionless for more than 30 seconds or when firefighter presses the emergency button

- Some models may activate when temperature exceeds a preset limit

- Must be at least 95 decibels (dBA) and go off continuously for at least one hour

Potential Uses

- Assist rescuers locating trapped, unconscious, or incapacitated firefighters

- Useful in total darkness, dense smoke, and confined spaces

Device

- May be stand-alone or integrated

- May activate automatically or manually

- Modes

- Off

- Alarm

- Sensing

- Pre-alarm

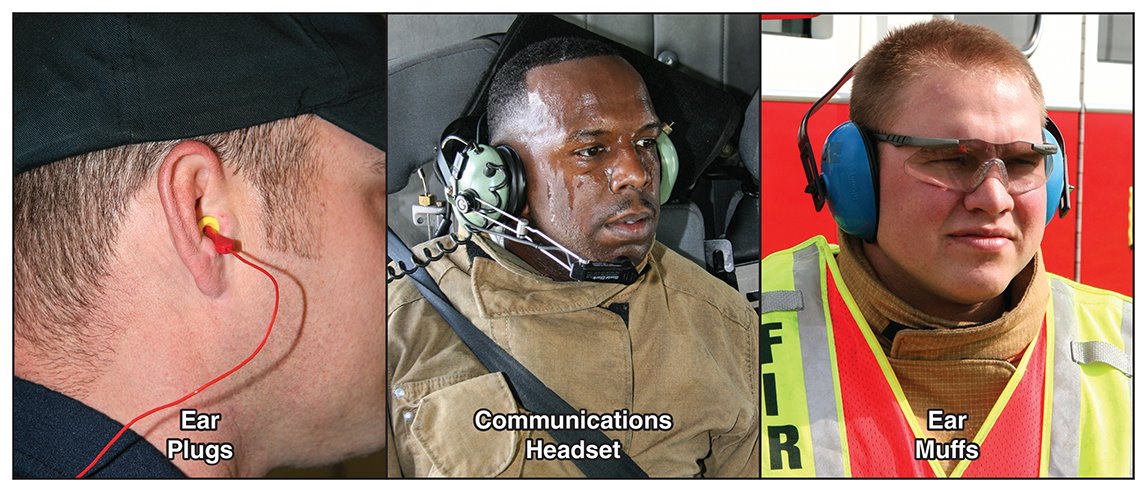

Hearing Protection

Firefighters are exposed to a variety of loud noises in the fire station, during training, en route to incidents, and at the emergency scene. Hearing protection devices guard against temporary and permanent hearing loss (Figure 5.17).

NFPA 1500 requires hearing protection devices. To comply with this standard, departments must protect firefighters from the effects of harmful noise. Eliminating or reducing noise is the best solution, but sometimes this is not possible. In these cases, departments must provide hearing protection devices and establish a hearing conservation plan.

Firefighters should use hearing protection when riding on an apparatus where the noise exceeds maximum noise exposure levels (90 decibels in the U.S., 85 decibels in Canada). Intercom/ear protection systems are most effective for this purpose. They also allow the crew to communicate with each other or monitor radio communications.

You must also wear hearing protection when operating:

- Power tools

- Generators

- Apparatus pump

- PASS device tests

In some situations, hearing protection is impractical and may even be dangerous. For example, during structural firefighting, it prevents you from:

- Communicating with other firefighters

- Hearing changes in fire behaviour

- Hearing radio transmissions

- Hearing calls from a trapped victim

Wildland PPE Structural firefighting

PPE is generally too bulky, heavy, and hot to be practical for wildland fire fighting. NFPA 1977 contains the specifications for wildland fire fighting PPE and equipment.

Wildland PPE and equipment includes (Figure 5.18):

- Gloves: Made of leather or inherently flame-resistant materials. They protect the hand and wrist from sharp or hot objects, temperature extremes, and scalding water.

- Goggles: Protect the eyes from ash, embers, dust, and other particulates. • Jackets — Made of high-strength, flame-resistant fabric, such as aramid or treated cotton. May have a thermal liner for use in cold climates. The cuffs close snugly around the wrists, and the front of the jacket must close completely from hem to neck.

- Trousers: Made of the same material and design as the jackets. The leg cuffs must close securely around the boot tops.

- One-piece jumpsuits: One-piece protective garments are similar in design to the two-piece jacket and trousers ensemble.

- Long-sleeve shirts: Protective shirts are worn under the jackets. • Helmet — A lightweight helmet with chin straps that provides impact, penetration, and electrical insulation protection.

- Face/neck shrouds: Flame-resistant fabric that attaches to the helmet and protects the face and neck.

- Footwear: Typically lace-up safety boots with lug or grip-tread soles. Must be high enough to protect the lower leg. Because the steel toes in ordinary safety boots absorb and retain heat, they are not recommended for wildland fire fighting.

- Fire shelter: Fire-resistant aluminized fabric covers that protect the firefighter from convected and radiant heat. NFPA 1500 requires its use, and its design must meet the United States Department of Agriculture (USDA) Forest Service Specification 5100-606.

- Load-carrying or load-bearing equipment: Belt and suspender systems that distribute the weight of the firefighter’s equipment.

- Respiratory protection: Beginning in 2011, NIOSH-certified, NFPA-approved air-purifying respirators (APR) and powered air-purifying respirators (PAPR) are available for wildland fire fighting.

- Chain saw protection: Chaps, leggings, or protective trousers made of ballistic nylon fibres that protect the legs.

- Fusees: Pyrotechnic flares used in wildland firefighting to start controlled burns.

In addition, most wildland fire agencies also provide firefighters with a canteen or bottled water and a backpack or web belt for carrying extra gear. Firefighters carry fusees, extra food, water, clean socks, and other items in these packs.

Wildland protective garments will not protect you from extreme heat. As with structural firefighting gear, you should never wear underclothing made of synthetic materials, such as nylon, polyester, iron-on patches, or transfer decals, when fighting a wildland fire. These materials melt when heated and can stick to your skin, causing serious burns. Refer to your department’s policies on what underclothing is approved at wildfire incidents.

![]()

In the absence of full, wildland firefighting gear, NFPA 1500 specifies the minimum PPE for firefighters to participate in ground cover firefighting. This standard requires firefighters to be equipped with the following:

- Helmet with eye protection and neck shroud

- Flame retardant shirt and pants (or one-piece jumpsuit)

- Protective footwear (sturdy boots without steel toes)

- Gloves

- Fire shelter (in crush-resistive case)

Figure 5.19 Firefighters should wear reflective safety vests when working on or near roadways.

Roadway Operations Clothing

Emergency operations along roadways are extremely dangerous for firefighters and emergency responders. No amount of PPE can prevent injuries when a person is struck by a rapidly moving vehicle. The best protection is to be visible to motorists and to work behind a barrier formed by your apparatus, as discussed in Chapter 2.

U.S. Department of Transportation (DOT) regulations require all personnel at roadway incidents to wear high-visibility vests. These vests should be at a minimum rated ANSI 107, Class 2 or 3 (ANSI 207 rated vests are also options). These vests must have reflective trim and five-point breakaway fasteners at the shoulders, side, and waist to meet NFPA safety standards in the U.S. and the CSA Z1006 series of regulations in Canada. Reflective trim on structural PPE does not provide enough visibility to meet these standards. You should wear vests over your PPE, if possible, but not while performing firefighting or hazardous materials activities at the scene. Wear the vest only after you have completed these activities or if you have been assigned duties other than firefighting or hazardous materials control (Figure 5.19).

Safety Considerations for PPE

PPE is designed to create a protective barrier between you and your work environment. However, this barrier can also isolate you, preventing you from being aware of important environmental changes and making you overconfident in your own safety (Figure 5.20).

Important safety considerations that relate to your personal protective equipment:

Understanding Your Gear

- Always consider the design and purpose of your protective clothing.

- Especially be aware of each garment’s limitations.

Moisture Risks

- Moisture in the shell and liner material can transfer heat rapidly, resulting in serious steam burns.

- Always ensure that the garment is dry before wearing it into a fire.

Heat Insulation and Awareness

- PPE acts as insulation from the intense heat of a fire, which can protect life but may also delay the sensation of rising temperatures.

- Regularly assess the thermal environment to maintain situational awareness.

Proper Fit for Maximum Protection

- Always wear PPE that fits correctly; improper fit can significantly reduce its protective efficacy.

- Tight clothing

- Does not close properly

- leaves gaps in the protective materials

- Loose clothing

- Can hinder mobility and dexterity by bunching up at shoulders, elbows, and knees

- Can snag on debris

- Can create a tripping hazard

- Can absorb contaminants

- Can reduce thermal protection

- Overlap

- Make sure that the overlap between coat and trousers is a minimum of 2 inches (50 mm) at the waist when you bend over at a 90° angle.

PPE Physical Effects

- Donning standard protective clothing will significantly impair your balance and gait (manner of walking).

- Thermal burns may occur at compression points where the garment layers are pressed together, such as under the SCBA shoulder harness, along sleeves in contact with hose lines, and on knees when kneeling on hot debris and embers.

Thermal Saturation Awareness

- The thermal environment will heat the exterior of the PPE resulting in thermal saturation that can cause contact burns.

- If you feel contact burns developing, withdraw from the area immediately.

- Thermal Saturation: Point at which a liquid or solid can no longer absorb heat without undergoing a physical change, whether vaporization in liquids or pyrolization in solids.

Sweating and Heat Stress Management

- Prolonged exposure to hot environments will cause your body to sweat to cool itself down.

- The protective clothing liner will retain the moisture produced by sweating, which may cause heat stress or burns.

- When you feel the symptoms of heat exhaustion, including weakness, dizziness, rapid pulse, or headache, move to a cool, safe area. Remove your PPE and follow established rehabilitation procedures.

PPE Limitations

-

Figure 5.21 PPE may need to be cut away from a downed firefighter if the PPE’s Velcro fasteners fuse together. PPE is designed to protect you, but it is not designed to protect against fire conditions such as backdraft, flash-over, or other rapid fire development.

- PPE absorbs heat which delays heat transfer to the wearer. This heat can build until the PPE is hotter than the ambient temperature.

- Heating of PPE’s Velcro® fasteners can fuse the Velcro® components together. In such cases, the PPE will need to be cut open to remove it from the firefighter (Figure 5.21).

- Eventually, the buildup of heat will penetrate through all layers of the PPE and can cause burns and raise the firefighter’s temperature.

- RIT and rescue personnel must exercise caution and wear their fire-fighting gloves when trying to remove fire-fighters from super-heated PPE. The heat of the PPE can burn rescuers’ hands.

![]()

Test Your Knowledge!

Lesson 2

Outcomes:

- Describe the inspection, cleaning, and maintenance of PPE.

Preparation of PPE for Reuse

Your PPE is your primary barrier protecting you from injury and illness. However, it can also cause injury or illness if it is not properly maintained. Hydrocarbon contamination will reduce the fire resistance of your PPE. Chemicals, oils, and petroleum products in or on the outer shell can ignite when exposed to fire. Some contaminants can reduce the effectiveness of retroreflective trim, and soot can obscure its visibility. Hydrocarbons, body fluids, and toxins that contaminate PPE can be inhaled, ingested, or absorbed, causing serious and sometimes fatal illness.

You are responsible for the inspection, cleaning, and condition of the PPE assigned to you. You can find procedures for the care of your PPE in your department’s SOPs, the manufacturer’s instructions, and NFPA 1851.

Inspecting PPE for Damage or Contamination

You should frequently inspect your PPE. Inspection periods should occur (Figure 5.22):

- At the start of your work shift

- After every use

- After washing, repair, or decontamination

- On a periodic basis, such as weekly or monthly

Conditions that you should look for during a routine inspection include:

- Soiling

- Contamination

- Missing or damaged hardware and closure systems

- Physical damage including rips, tears, fraying hems and cuffs, and damaged stitching on seams

- Wear due to friction under arms, in the crotch, and at knee and elbow joints

- Thermal damage, including charring, melting, discolouration, and burn holes

- Shrinkage

- Damaged or missing retroreflective trim or reinforcing trim

- Loss of reflectivity of shell on proximity equipment

- Cracks, melting, abrasions, or dents in helmet shell

- Missing or damaged face shield or hardware

- Missing or damaged earflaps or neck shroud

- Loss of watertight integrity in footwear

- Damage to or faulty installation of drag rescue device (DRD)

- Date of manufacture to determine time in service

If your protective clothing requires only routine cleaning that will not cause the item to be removed from service, you should perform the cleaning yourself. If you ever determine that your PPE requires advanced cleaning or decontamination, repairs, or replacement, report this to your supervisor immediately. A member of your department who is trained in advanced inspection requirements, such as the department’s Health and Safety Officer (HSO), should perform an annual inspection.

Cleaning PPE

The amount and type of contamination and whether the equipment must be removed from service determines the type of cleaning.

NFPA 1851 defines four types of cleaning for PPE:

- Routine cleaning

- Specialized cleaning

- Advanced cleaning

- Contract cleaning

Many fire departments provide spare sets of PPE to replace units removed from service for cleaning, decontamination, or repairs. NFPA standards recommend that each firefighter be issued two sets of structural firefighting PPE. Having two sets of gear ensures that one set of gear can be laundered immediately following an incident while the spare set can be donned in case there is an incident before the first set is cleared. Wearing uncontaminated PPE is a preventative measure against the risk of cancer later in life.

Routine Cleaning

- Routine cleaning does not require that the clothing be removed from service.

- At an incident scene, the process for routine cleaning includes:

- Brushing off loose debris with a broom or soft bristle brush

- Using a gentle spray of water to rinse off debris and soil

- To remove heavy soil, clean PPE manually in a utility sink in the designated cleaning area at the fire station (Figure 5.23)

- Whether you are at the scene or in the station, always follow the manufacturer’s recommendations and wear appropriate gloves and eye protection.

Advanced Cleaning

- Personnel trained in the care and cleaning of protective clothing should perform advanced cleaning.

- Those personnel should use a washing machine dedicated to cleaning protective clothing that is designed to handle heavy loads (Figure 5.24).

Specialized Cleaning

- Specialized cleaning is required when clothing is contaminated with hazardous materials or body fluids that cannot be removed by routine or advanced cleaning.

- A trained department member or an outside contractor may perform the cleaning.

Contract Cleaning

- Contract cleaning typically removes accumulated grime or contaminants.

- Contractors who perform specialized cleaning may include the manufacturer, the manufacturer’s representative, or a certified vendor.

- Some contractors provide replacement PPE while clothing is being cleaned.

Repairing PPE

The manufacturer, an approved repair facility, or a trained department member must remove damaged protective clothing immediately. Clothing damaged beyond repair must be removed from service and destroyed. Some damaged clothing may be marked “for training use only” and used in training that does not involve fire.

Test Your Knowledge!

Lesson 3

Outcomes:

- Describe conditions that require the use of respiratory protection equipment.

Self-Contained Breathing Apparatus (SCBA)

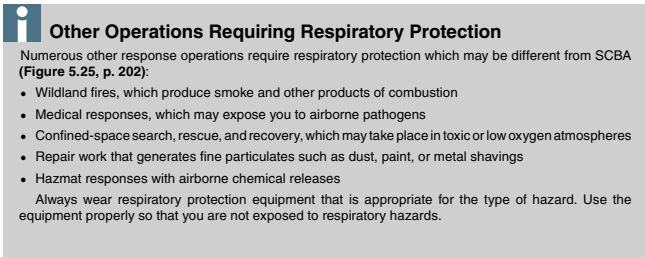

Inhalation of smoke and other products of combustion poses short-term, long-term, and even fatal health hazards. Wearing appropriate respiratory protection is the most effective way to protect your health.

The use of self-con-trained breathing apparatus (SCBA) is a required skill for firefighters according to NFPA 1001. Operations requiring SCBA protection include any activities that may take place in or near a potentially immediately dangerous to life and health (IDLH) environment as defined in the AHJ’s policies. Research also indicates that firefighters should wear SCBA during overhaul operations (Horn, et al. 2016). By-products of combustion present during overhaul can cause long-term health risks such as cancer or respiratory disease.

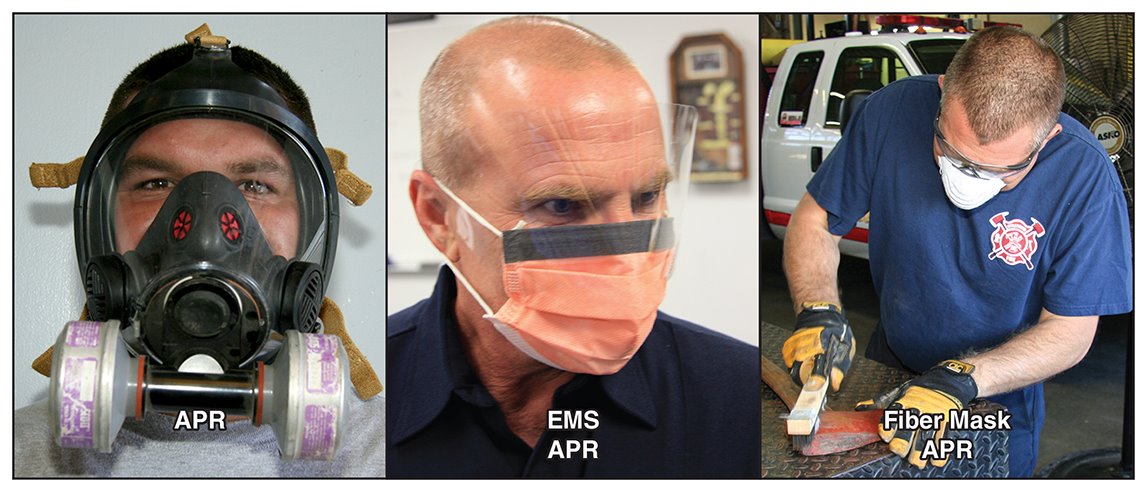

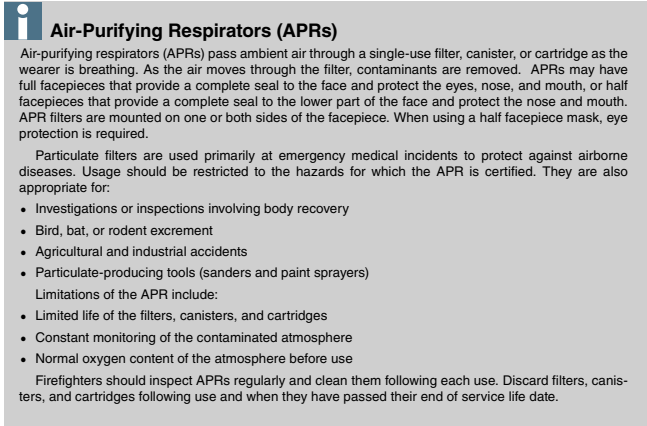

Types of Respiratory Protection Equipment

The two categories of respiratory protection equipment are atmosphere-supplying respirators (ASRs) and air-purifying respirators (APRs). ASRs provide breathable air when working in oxygen-deficient, toxic, or gas-filled atmospheres, while APRs only filter particulates out of the surrounding air. The primary type of respiratory protection that you will use in the fire service is the ASR.

Respiratory Hazards

Respiratory hazards are common in situations that produce immediate, irreversible, and debilitating effects on a person’s health and may result in death. NFPA 1500 and OSHA classify these situations as IDLH. Before entering a potential IDLH structure or area, you must don the correct level of PPE and respiratory protection.

Common respiratory hazards include:

- Oxygen deficiency

- Elevated temperatures

- Particulate contaminants

- Gases and vapours

- Airborne pathogens

Oxygen Deficiency

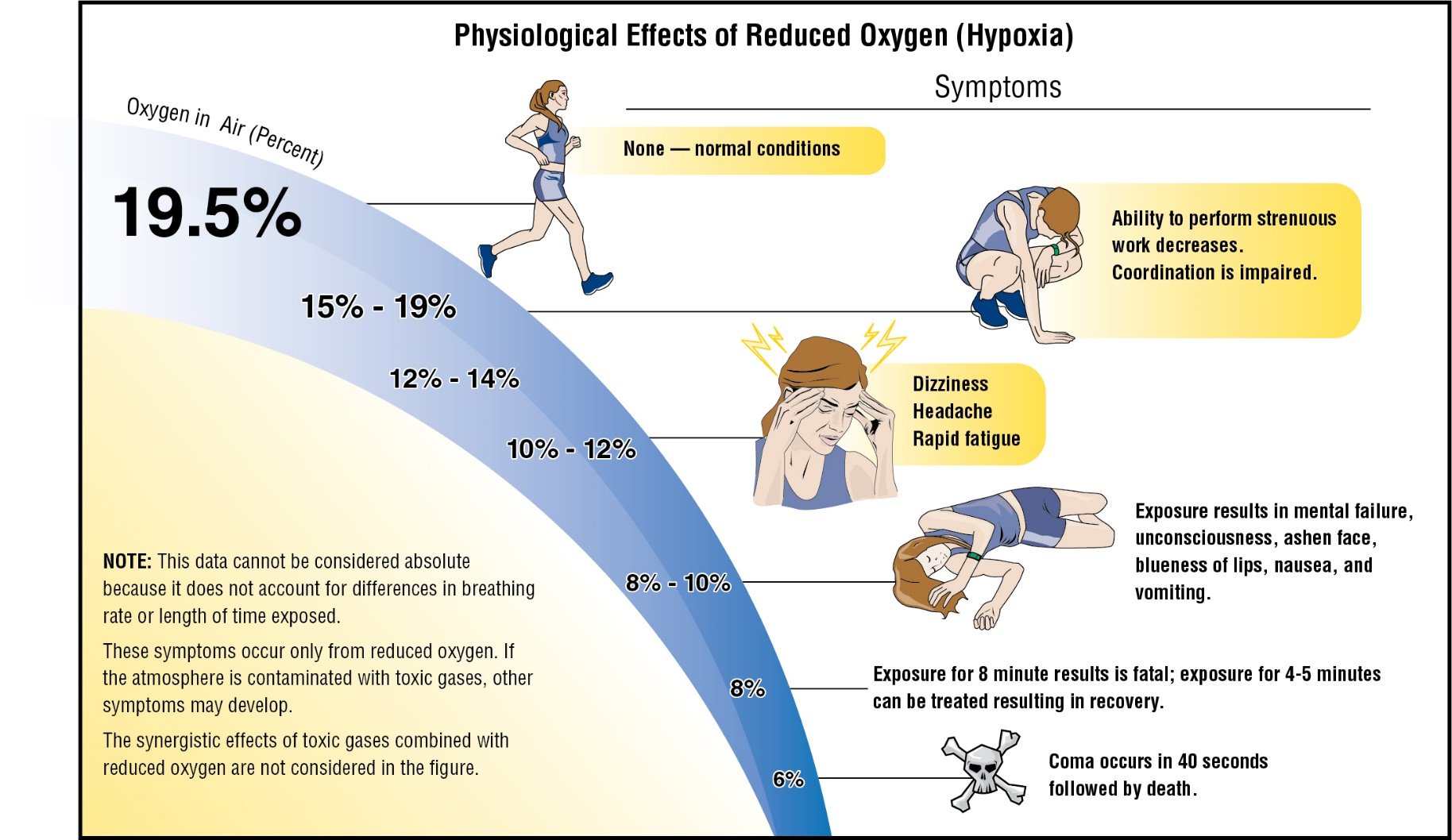

Both NFPA and OSHA define an oxygen-deficient atmosphere as one containing less than 19.5 percent oxygen. When oxygen concentrations fall below 18 percent, the human body increases its respiratory rate. As less oxygen reaches body tissues, hypoxia occurs. Figure 5.26 illustrates the physiological effects of hypoxia.

Combustion is the most common cause of oxygen-deficient atmospheres. It consumes oxygen and produces toxic gases, which physically displace oxygen or dilute its concentration. Oxygen-deficient atmospheres also occur in confined spaces (sewers, chemical storage tanks, grain bins, underground caverns) or where carbon dioxide (CO2) total-flooding extinguishing systems have discharged.

Some fire departments have instruments to monitor atmospheres and measure oxygen levels or the presence of toxic gases. Where monitoring is not possible or monitor readings are questionable, firefighters should wear SCBA.

Elevated Temperatures

Breathing air that has been heated to flame temperatures normally found during a structure fire can seriously damage the respiratory tract. The damage can be much worse when the air is moist. Excessive heat inhaled quickly into the lungs can cause a serious decrease in blood pressure and failure of the circulatory system. Inhaling heated gases can cause pulmonary edema which can cause asphyxiation. Introducing fresh, cool air will not immediately reverse tissue damage. The condition requires prompt medical treatment.

Particulate Contaminants

Particulate contaminants are small particles that may be suspended in the air and are harmful to the respiratory system. Smaller particulates are especially dangerous because the nasal membranes filter particulates bigger than one micro-metre but cannot keep the smaller particulates from entering the lungs.

Sources of these particulates include:

- Vehicle exhaust emissions (Figure 5.27)

- Chemical reactions

- Heated metals or metal compounds

- Combustion

Exposure to particulate contaminants can cause the following:

- Asthma

- Lung cancer

- Cardiovascular disease

- COPD

- Premature death

Firefighters may encounter particulate contaminants in a variety of operations, including the following:

- Wildland fires

- Welding and metal-cutting operations

- Operation of fire apparatus and small engines

- Operations following an explosion or building collapse

- Structural fires, especially during the overhaul phase

Air-purifying respirators (APRs) and powered air-purifying respirators (PAPRs) are generally sufficient to protect you from particulate contaminants. Cartridge and canister-type APR/PAPRs have half or full–facepiece units with replaceable filter elements that capture the particulates (Figure 5.28).

APR/PAPRs are approved for wildland fire fighting but do not protect against toxic gases or heated or oxygen-deficient atmospheres. APR canisters or cartridges exposed to increased levels of oxygen (above 23 percent) may also yield unknown, adverse reactions that require you to evacuate.

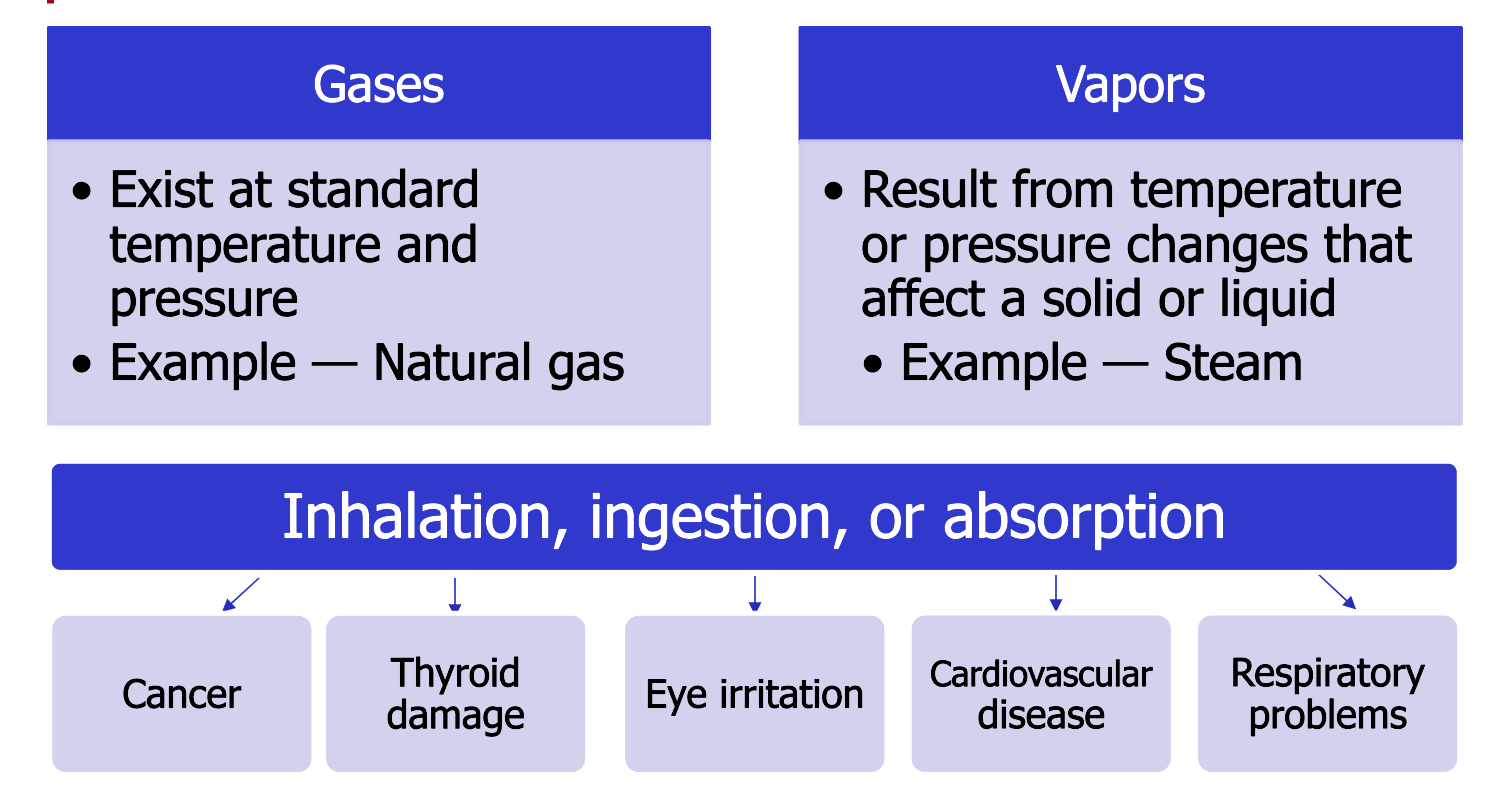

Gases and Vapours

Gases and vapours may be present at both fire and non-fire incidents. Gases exist at standard temperature and pressure, while vapours result from temperature or pressure changes that affect a solid or liquid. For example, natural gas is commonly found in a gaseous state, while steam is a vapour created when water is heated.

Gases and vapours can be inhaled, ingested, or absorbed into the body, resulting in illnesses and death. Exposure may cause:

- Cancer

- Thyroid damage

- Cardiovascular disease

- Respiratory problems

- Eye irritation

In Fire Gases and Vapours

Combustion creates harmful gases and vapours including:

- Carbon monoxide (CO)

- Carbon dioxide (CO2)

- Hydrogen cyanide (HCN)

- Hydrogen chloride

- Hydrogen sulfide

- Phosgene

- Nitrous gases

- Sulfur dioxide

- Ammonia

- Formaldehyde

**NOTE: For further information on CO, CO2, and HCN, refer to Chapter 4: Fire Dynamics.**

As the products of combustion are potentially deadly, firefighters must use SCBA when operating in or near toxic atmospheres. Although smoke volume and density considerably diminish during overhaul, the respiratory hazard remains. Hazardous concentrations above short-term exposure limits are likely to be present during overhaul. In many cases, the hazards from smoke increase as the size of the particulates decreases. You are less likely to see the particulates that can penetrate the deepest into your lungs. Hazardous concentrations may also be present in areas outside the structure.

Non-fire gases and vapours

Hazardous materials (hazmat) can produce potentially hazardous gases and vapours

in non-fire emergencies, such as the following:

- Incidents involving industrial, commercial, or warehouse occupancies

- Spills resulting from transportation accidents

- Leaks from storage containers or pipelines

At any hazmat incident, always remain at a safe distance (upwind, uphill, upstream) until the completion of a risk analysis. You should always consider the atmosphere at these incidents dangerous, so you must wear your SCBA until air monitoring demonstrates that the atmosphere is safe.

Hazardous nonfire gases and vapours are always a possibility at transportation incidents and in storage and manufacturing facilities.

Common nonfire gas and vapour types include:

- Carbon Dioxide: Produced by fire suppression systems

- Ammonia: Found in air conditioning and cooling systems, chilling systems for hockey rinks, and agricultural applications

- Sulphur Dioxide: Produced by air conditioning and cooling systems

- Chlorine: Found in water treatment facilities, water parks, and swimming pools

- Pesticides: Found in commercial outlets, farms, nurseries, and residences

Toxic gases may also be found in:

- Sewers

- Caves

- Storage tanks

- Bins

- Storm drains

- Trenches

- Tank cars

- Other confined spaces

The atmosphere in these areas may also be oxygen deficient and potentially deadly. Search, rescue, and recovery in these areas require the use of SCBAs.

Airborne Pathogens

Airborne pathogens are disease-causing microorganisms (viruses, bacteria, or fungi) suspended in the air. Airborne pathogens cause infection through inhalation or direct contact.

You may encounter airborne pathogens during:

- Medical responses

- Vehicle extrications

- Rescue and recovery operations

Terrorist attacks

Protection against airborne pathogens includes high-efficiency particulate air (HEPA) filters, APR/PAPRs, and SCBA (Figure 5.29). HEPA filter masks are single-use masks. Surgical masks are not approved for use against airborne pathogens but may be used on patients to prevent them from spreading diseases by exhaling, sneezing, or coughing.

Key Terms

Atmosphere-supplying respirators (ASRs): Provide breathable air when working in oxygen-deficient, toxic, or gas-filled atmospheres.

Air-purifying respirators (APRs):Filters particulates out of the surrounding air.

Airborne pathogens:Disease-causing microorganisms (viruses, bacteria, or fungi) suspended in the air.

Hypoxia:A condition in which there is an insufficient supply of oxygen in the tissues of the body.

Pulmonary edema:A condition characterized by excess fluid in the lungs’ air sacs, making it difficult to breathe.

High-efficiency particulate air (HEPA) filter:A type of air filter that can trap 99.97% of particles that are 0.3 microns in diameter or larger.

Test Your Knowledge!

Lesson 4

Outcomes:

- Identify SCBA components

SCBA Components

SCBA is a type of atmosphere-supplying respirator that provides air in a cylinder.

There are two main types of SCBA (Figure 5.30)

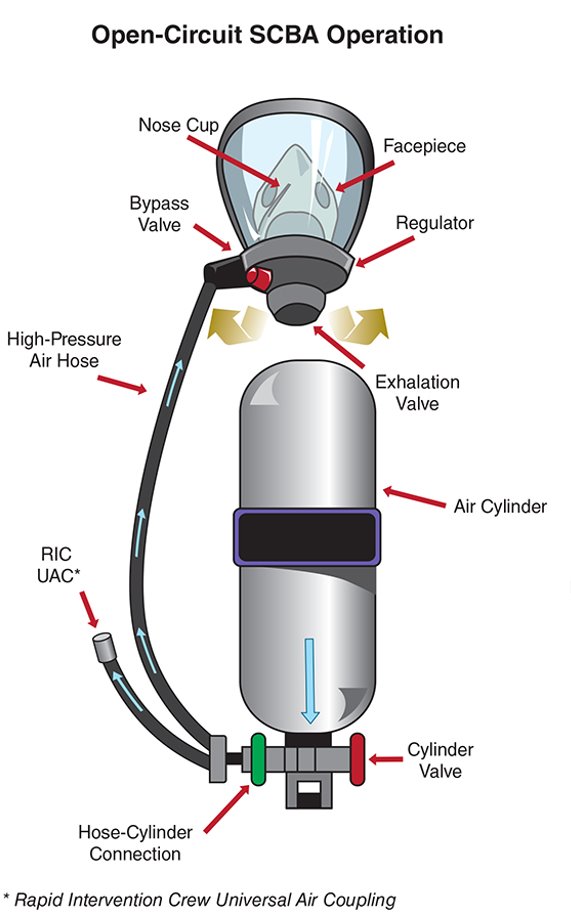

Open-circuit SCBAIt vents exhaled air to the outside environment using compressed air. Open-circuit SCBA consists of four basic components (Figure 5.31):

|

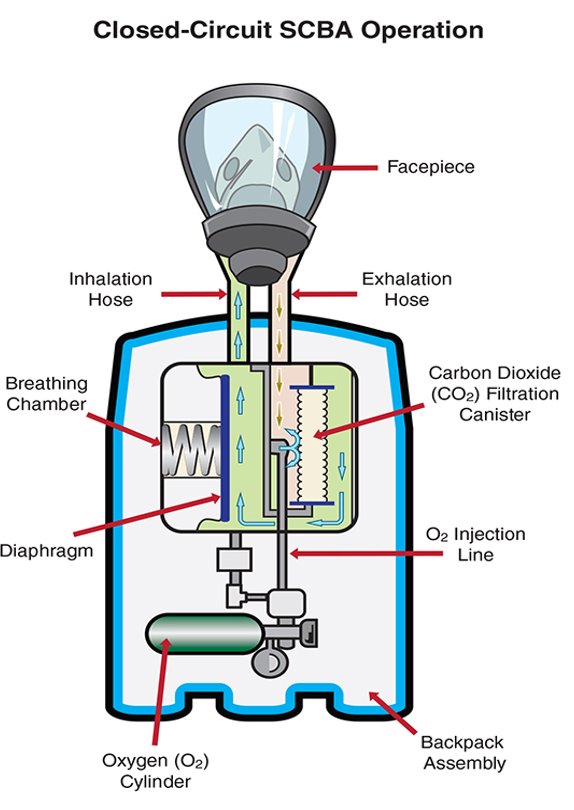

|

Closed-circuit SCBA (aka “rebreather” apparatus)Using compressed oxygen, it removes the CO2 from the exhaled air, injects fresh into that air, and recirculates the re-oxygenated air to the facepiece. Closed-circuit SCBA are much less common and are mainly used:

|

|

**NOTE:SCBA may also have several other components unique to that manufacturer’s design.**

Open-Circuit SCBA

Backplate and Harness Assembly

A rigid frame with adjustable straps holds the breathing air cylinder on the backplate, and onto the firefighter’s back. The straps stabilize the unit, carry part of its weight, and provide a secure and comfortable fit. An adjustable waist strap also distributes some of the apparatus’ weight to the hips.

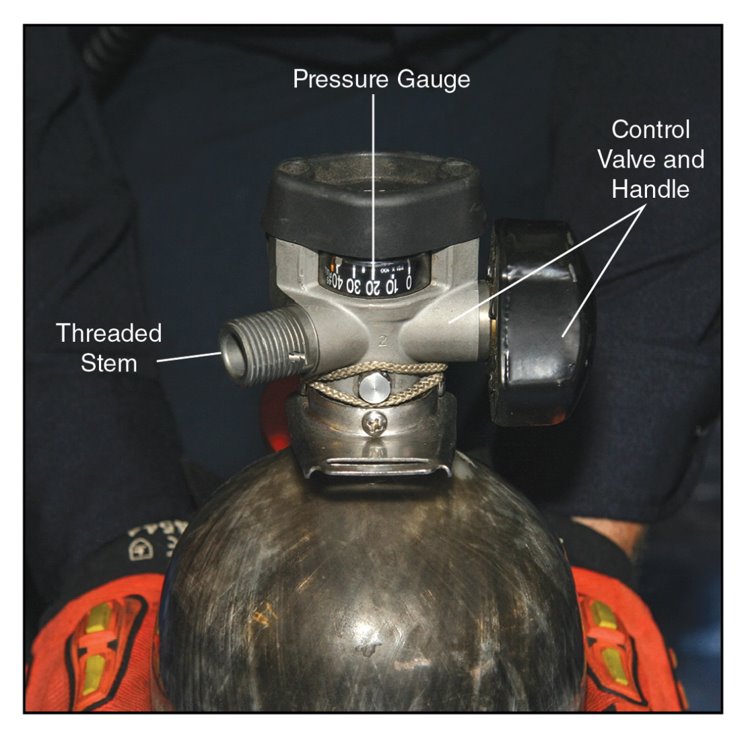

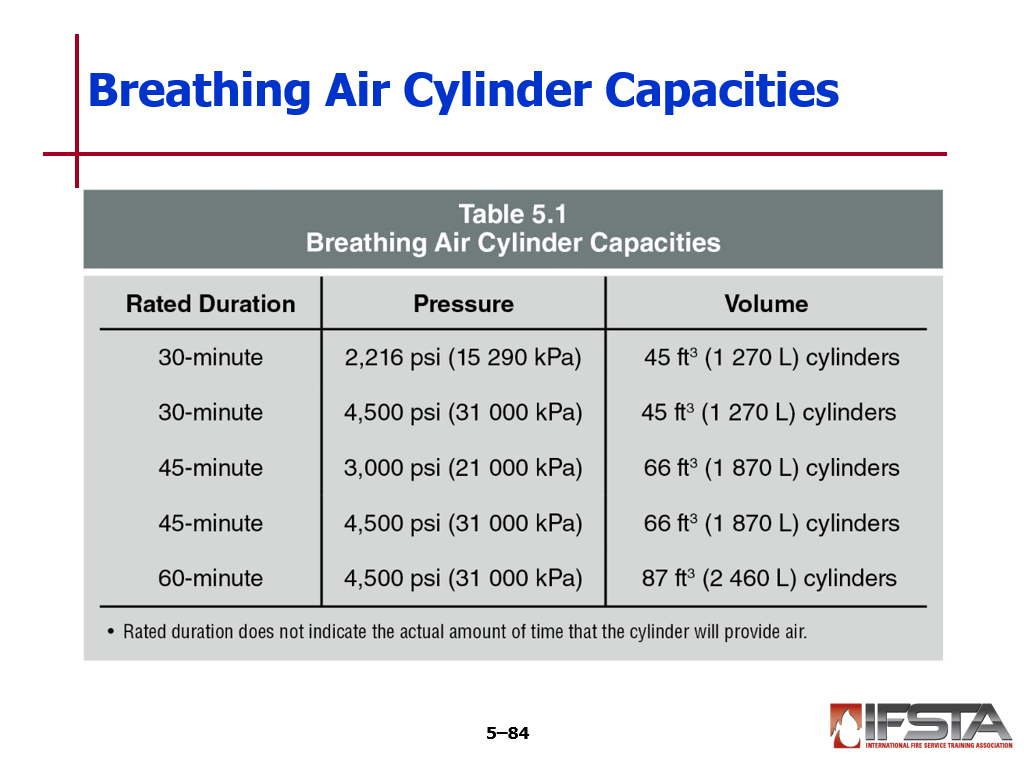

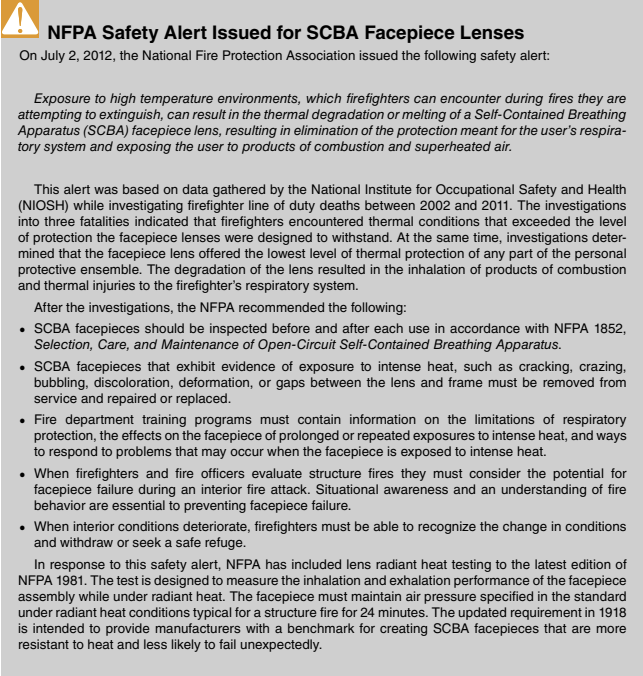

Air Cylinder Assembly

The air cylinder contains breathing air under pressure. It may be constructed of steel, aluminum, aluminum wrapped in fibreglass, or a Kevlar/carbon composite material. Table 5.1 shows common cylinder capacities.

Depending on the size and construction materials, cylinders weigh approximately 8 to 20 pounds (4 to 9.5 kg). This weight significantly increases physical stress during emergency operations.

The cylinder has a control valve, threaded stem and/or quick-connect fitting, and a pressure gauge attached to one end (Figure 5.32). When the cylinder is in operation, the wearer fully opens the control valve to permit air into the system. The high-pressure hose attaches to the stem and connects the cylinder to the regulator assembly. Air from the cylinder travels through the high-pressure hose to the regulator. The pressure gauge displays an estimate of the amount of air in the cylinder in pounds per square inch (psi) (kilopascal [kPa]).

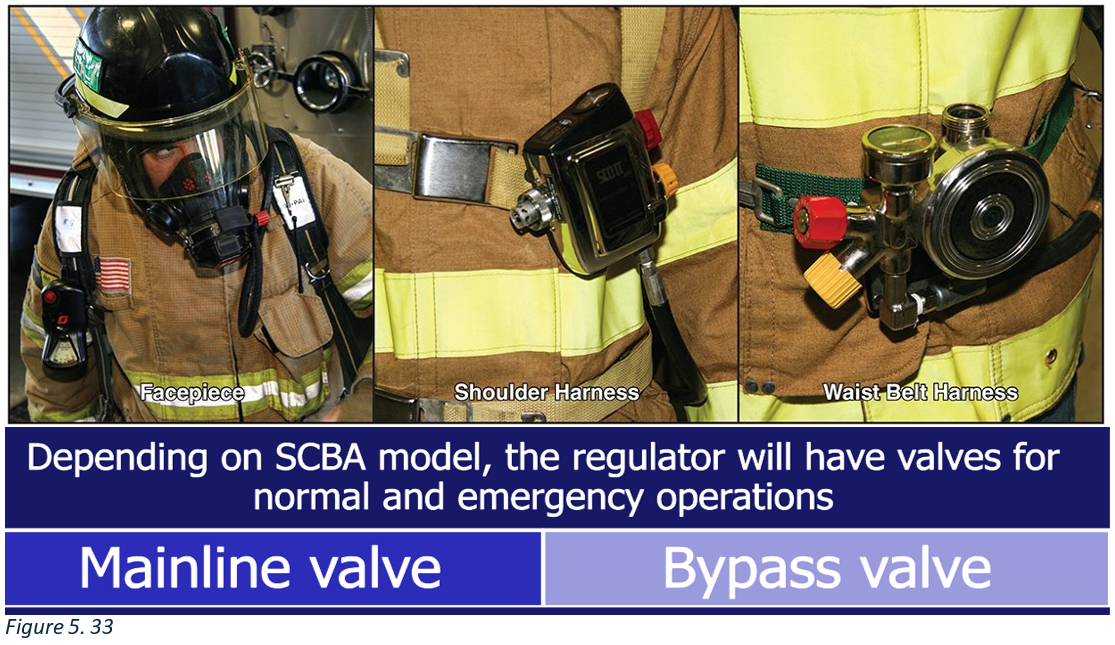

Regulator Assembly

The regulator reduces the high pressure of the cylinder air to slightly above atmospheric pressure and controls air flow to the wearer. When the wearer inhales, a pressure differential occurs in the regulator. The apparatus diaphragm moves inward, tilting the admission valve so that low-pressure air can flow into the facepiece. The regulator diaphragm is then held open, which creates the positive pressure. Exhalation moves the diaphragm back to the “closed” position. The regulator may be located on the facepiece, the shoulder harness, or the waist belt harness (Figure 5.33).

Depending on the SCBA model, the regulator will have control valves for normal and emergency operations. These are the mainline valve and the bypass valve. On models equipped with both valves, the mainline valve locks in the open position during normal operations and the bypass valve is closed. On some SCBA, the bypass valve controls a direct airline from the cylinder in the event that the regulator fails. Once the valves are set in their normal operating position, they should not be changed unless the wearer needs the emergency bypass function. The current generation of regulators includes only the bypass valve.

Depending on the SCBA model, the regulator will have control valves for normal and emergency operations. These are the mainline valve and the bypass valve. On models equipped with both valves, the mainline valve locks in the open position during normal operations and the bypass valve is closed. On some SCBA, the bypass valve controls a direct airline from the cylinder in the event that the regulator fails. Once the valves are set in their normal operating position, they should not be changed unless the wearer needs the emergency bypass function. The current generation of regulators includes only the bypass valve.

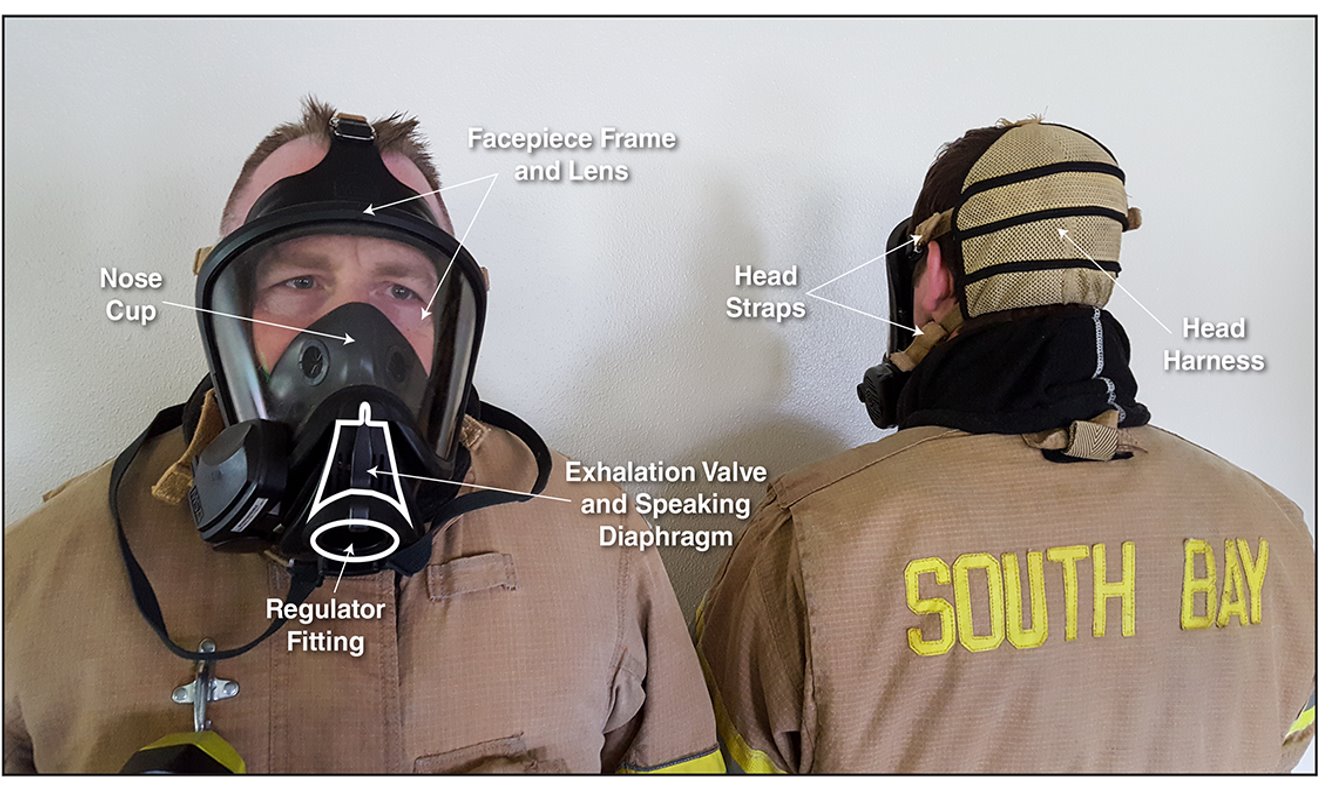

Facepiece Assembly

The facepiece assembly provides fresh breathing air while protecting the eyes and face from injury. To accomplish these functions, the facepiece must fit tightly to the face.

The facepiece assembly consists of (Figure 5.34):

- Facepiece frame and lens: Made of clear safety plastic and mounted in a flexible rubber facepiece frame. According to NFPA 1981, all new SCBA facepieces must be equipped with a heads-up display (HUD). This feature displays a series of lights on the inside of the facepiece lens indicating the approximate amount of air remaining in the cylinder.

- Head harness and straps: This harness, with adjustable straps, net, or some other arrangement, holds the facepiece snugly against the face.

- Exhalation valve: Simple, one-way valve that releases exhaled air without admitting any of the contaminated outside atmosphere.

- Nose cup: Deflects exhalations away from the lens, reducing fogging or condensation on the lens.

- Speaking diaphragm: This mechanical diaphragm grants the wearer limited communication. It may be replaced by an electronic speaking diaphragm connected to a portable radio.

- Regulator fitting or hose connection: Permits the regulator or hose to attach to the facepiece frame.

Facepiece Fit-Test

- Firefighters must undergo a fit test of their facepiece to determine the correct fit for a proper seal (Figure 5.35).

- The test must use the same make, model, style, and size of facepiece that will be worn during emergency operations.

- OSHA currently accepts two types of tests which both provide an adequate assessment of a facepiece’s ability to maintain a complete seal to the face.

- Qualitative fit-tests (QLFT): Respirator fit-test that measures the wearer’s response to a test agent, such as irritant smoke or odorous vapour. If the wearer detects the test agent, such as through smell or taste, the respirator fit is inadequate.

- Quantitative fit-tests (QNFT): Fit-test in which instruments measure the amount of a test agent that has leaked into the respirator from the ambient atmosphere. If the leakage measures above a pre-set amount, the respirator fit is inadequate.

- Fit tests should occur annually or on a regular schedule to ensure that the facepiece still creates an air-tight seal.

- NFPA 1500 prohibits beards or facial hair that prevents a complete seal.

- Wearing eyeglasses is prohibited if the side frames pass through the seal area.

- Eyeglass kits are provided with all full facepiece masks.

- Both NFPA 1500 and Code of Federal Regulations (CFR) 1910.134 allow firefighters to wear soft contact lenses while using full facepieces if the firefighter has demonstrated successful long-term (at least 6 months) use of them.

Additional SCBA Components

Manufacture of SCBA varies depending upon the features included in their designs. Many of the components in this section are becoming standard on newer model SCBA and are included in NFPA 1981 for testing and specifications. Older but still serviceable SCBA may not include these components.

Remote pressure gauge: Pressure gauge that is not mounted on the regulator but can be seen by the SCBA wearer; commonly found on SCBA that have facepiece-mounted regulators.

A remote pressure gauge must be mounted in a visible position to display the air pressure within the cylinder (Figure 5.36). Pressure readings are most accurate at or near the upper range of the gauge’s rated working pressures. Low pressure is measured less accurately, so the readings at this low end of the scale may not match the reading on the regulator gauge. When this occurs, assume that the lowest reading is correct. Check to make sure that the equipment is in working order before using it again.

End-of-service-time indicator (EOSTI)

NFPA and NIOSH require that two end-of-service-time indicators (EOSTI) or redundant low-pressure alarms be installed on all SCBAs. The EOSTI’s alarm warns the user that the system is reaching the end of its air supply, typically when it reaches 33 percent of the cylinder’s capacity (Figure 5.37). The EOSTI has both an audible alarm (like a bell, electronic beep, or high-pitched siren) and a flashing light or physical vibration. The alarm cannot be turned off until the air cylinder valve is closed, and the system is bled of all remaining pressure.

Rapid intervention crew universal air coupling (RIC UAC)

All new SCBAs are equipped with a rapid intervention crew universal air coupling (RIC UAC) located within 4 inches (100 mm) of the cylinder outlet. This allows any cylinder that is low on air to be trans-filled from another cylinder, regardless of its manufacturer (Figure 5.38). When the cylinders are connected, the air supply equalizes between them. Older SCBA can be retrofitted with the RIC UAC, but this is not required. The use of this feature requires thorough training.

Emergency Escape Breathing Support System (EEBSS)

- A firefighter with a malfunctioning SCBA can connect his or her regulator to the buddy breathing output on the working SCBA (Figure 5.39).

- As both firefighters use the same air, they should make their way out of the dangerous environment toward the nearest means of emergency egress or the nearest safe haven.

Integrated PASS control module

- PASS control module: Contains analog or digital displays to provide information about the operation of the SCBA and PASS device.

- The displays are required to show the remaining breathing air cylinder content.

- Manufacturers may also include other vital information such as:

- Cylinder pressure

- Alarms

- Remaining battery life

- Estimates for remaining operational time

Heads–up display (HUD)

- Heads-up displays show vital equipment information on the inside of the facepiece.

- May be integrated into the facepiece or mounted on the shoulder and projecting an image to the facepiece (Figure 5.40).

- NFPA 1581 regulations:

- HUD must display the breathing cylinder content at least in 100, 75, 50, and 33 percent increments.

- The display should flash at one percent increments to indicate to the wearer the rate at which air is being used.

- Manufacturers may also include other information as part of the display depending upon their designs.

Alert lighting systems

- The lights of this SCBA facepiece’s heads-up display provide a constant reminder of the available air pressure in an air cylinder. Courtesy of Arlington (TX) Fire Department. Photograph by Jason Arias.

All PASS devices are designed to emit an alarm when they activate. - Some manufacturers will also include a lighting system in the SCBA harness that flashes emergency signals when the device activates.

- The intention is for rescuers to receive both a visual and audio signal to follow when searching for a downed firefighter.

Voice communications systems

- Some manufacturers integrate voice communication systems into SCBA to supplement radio communications.

- Firefighters can turn the systems on or off as needed, and NFPA 1581 allows the systems to have a volume control.

- Some systems are voice-activated, providing hands-free communications.

- The systems may also use a wired or wireless interface to connect to the firefighter’s radio rather than operate as a standalone replacement for a radio.

SCBA Protection Limitations

Although they protect you from a variety of hazards, all respiratory protection equipment has limitations. You must be aware of these limitations if you are going to operate safely and effectively in hazardous atmospheres. The wearer or the equipment itself may create limitations.

Wearer Limitations

The limitations that you have the greatest control over include:

- Lack of physical condition: If you are not in good physical condition or if you are overweight, you may deplete your air supply rapidly.

- Lack of agility:If you are not sufficiently agile, the weight and restriction of the equipment will make you less so, thus making it difficult to accomplish your assigned tasks.

- Impaired balance:Donning SCBA will significantly impair your balance and gait (manner of walk).

- Inadequate pulmonary capacity: You must have sufficient lung capacity to inhale and exhale sufficient air while wearing respiratory protection equipment.

- Weakened cardiovascular ability:You must have a strong enough heart to prevent heart attacks, strokes, or other related problems while performing strenuous activity.

- Psychological limitations:You must be able to overcome stress, fear, and feelings of claustrophobia while wearing respiratory protection equipment.

- Unique facial features:The shape and contour of the face can affect the ability to get a complete face-to-face seal. Weight loss or gain can alter the facepiece seal.

**NOTE:You can offset these limitations through constant training with each type of respiratory protection equipment you use, periodic medical evaluations, and proper fit testing of respiratory protection facepieces. Training will make you more confident and more effective while wearing respiratory protection equipment. **

Equipment Limitations

SCBA units have limitations, including:

- Limited visibility: The full facepiece can reduce peripheral vision, while facepiece fogging can reduce overall vision.

- Decreased ability to communicate: The facepiece can seriously hinder voice communication unless it has built-in voice amplification or a microphone connection.

- Decreased endurance: The weight of SCBA units, averaging between 25 and 35 pounds (12.5 and 17.5 kg), makes you tire more quickly.

- Decreased mobility: The increase in weight and the restrictions that the harness straps cause can reduce your mobility.

- Poor condition of apparatus: Minor leaks and poor valve and regulator adjustments can result in excess air loss.

- Low air cylinder pressure: If the cylinder is not filled to capacity, the amount of working time is reduced proportionately. You have some control over these limitations through frequent and proper inspections, care, and maintenance. Training with the units that you will use can also help you overcome the weight and mobility factors.

Lesson 5

Outcomes:

- Describe the procedures for donning and doffing SCBA.

Donning and Doffing Breathing Apparatus

Firefighters can use several methods to don an SCBA, depending on how it is stored. The most common include (Figure 5.41):

- Over-the-head method

- Coat method

- Donning from a seat

- Donning from a side/rear external mount or backup mount

Different brands and models also require different steps for securing the SCBA to the wearer. Because it is impossible to list these procedures for each manufacturer’s model, this section provides only a general description of the four different donning techniques. Make sure to follow the manufacturer’s instructions and local SOPs for the particular SCBA assigned to you.

General Donning Considerations

Firefighters with daily shift changes should perform daily inspections at the start of their shifts then return the SCBA to the apparatus-mounted storage rack or the storage case.

Departments that are unable to make daily inspections should perform the following checks immediately before donning the SCBA:

- Check the air cylinder gauge to make sure the cylinder is full. NFPA 1852, Standard on Selection, Care, and Maintenance of Open-Circuit Self-Contained Breathing Apparatus (SCBA), recommends no less than 90 percent of cylinder capacity (Figure 5.42).

- Check the remote gauge and cylinder gauge to ensure that they read within the manufacturer’s recommended limits.

- Check the harness assembly and facepiece to ensure that all straps are fully extended.

- Operate all valves to ensure that they function properly and are left in the correct position.

- Test the low-pressure alarm.

- Test the PASS device to ensure that it is working.

- Check all battery-powered functions.

Always refer to manufacturer’s instructions regarding any variations in SCBA use. For example, on some SCBA, the audible alarm does not sound when the cylinder valve is opened and not all facepieces are designed for a seal check without the regulator being attached and activated.

Donning an Unmounted SCBA

SCBA stored in cases can be donned using the over-the-head method and the coat method. In both methods, the SCBA must be positioned on the ground in front of the firefighter (either in or out of the case) with all straps extended, ready to don. The steps for donning structural PPE are described in Skill Sheet 5-1. The steps for donning SCBA using the over-the-head and coat methods are described in Skill Sheet 5-2.

Donning from a Seat Mount

Seat-mounted SCBA permits firefighters to don the unit while seated in the apparatus (Figure 5.43). You should only use this method only if you can do so without removing the apparatus seat belt. Even with a seat mount, jurisdictions may still have policies dictating when SCBA can be donned — before departure, in transit, or after arrival. The steps for donning SCBA from a seat mount are described in Skill Sheet 5-3.

NFPA 1901, Standard for Automotive Fire Apparatus, requires that the SCBA beheld in place by a mechanical latching device (Figure 5.44). There are a wide variety of mounting brackets available that meet this requirement. The facepiece should be stored in a drawstring or other quick-opening bag, or in a pouch on your protective coat. This will keep it clean and protect it from dust and scratches.

**NOTE: Do not keep the facepiece connected to the regulator during storage. These parts must be kept separate, in order to check for proper facepiece seal. **

The air cylinder’s position in the seat back should match the proper wearing position for the firefighter. A seat-mounted SCBA allows personnel to check the equipment more frequently and makes conducting safety checks more convenient.

Exit the apparatus carefully while maintaining three Anchor Points Cylinder points of contact because the extra weight of the SCBA on your back can make slips and falls more likely. Be sure to adjust all straps for a snug and comfortable fit.

Donning from a Side or Rear External Mount

Side-or rear-mounted SCBAare mounted on the exterior of the apparatus. Although this type of mount does not permit donning en route and requires more time for donning than seat-mounted SCBA, it reduces the chances of slips and falls. It is also faster than donning an SCBA stored in a carrying case because you do not have to remove the case from the apparatus, place it on the ground, open the case, and pick up the unit. Disadvantages of exterior mounting include exposing the SCBA to weather and other physical hazards, though waterproof covers will minimize the risk of damage.

If SCBA are mounted at the correct height, firefighters can don them with little effort. Having the mount near the running boards or tailboard allows the firefighter to don the equipment while sitting on the running board or tailboard. The donning steps are similar to those for seat-mounted SCBA.

Donning from a Backup Mount

Backup mounts located inside a compartment are protected from the weather and provide the same advantages as side- or rear-mounted equipment. The backup mount provides quick access to SCBA. However, some compartment doors may interfere with donning SCBA. Other compartments may be located too high on the apparatus, making donning more difficult.

One type of compartment mount has a telescoping frame that extends the equipment outward. Some of these also telescope upward or downward so that a standing firefighter can don the SCBA more quickly (Figure 5.45). The procedure for donning SCBA using the backup method is similar to the method used for seat-mounted SCBA. Some high-mounted SCBA must be removed from the vehicle and donned using the over-the-head or coat method.

Donning the Facepiece

Most SCBA facepieces are donned using similar steps. One important difference is that some facepieces use a rubber harness, while others use a mesh skullcap. Both have adjustable straps, although some models have more straps than others.

Another difference is the location of the regulator. It may be attached to the facepiece or mounted on the waist belt or shoulder harness. The shape and size of facepiece lenses may also differ. Despite these differences, donning procedures for facepieces are essentially the same.

The following are general considerations for donning all SCBA facepieces:

- Fully extend all straps.

- Ensure that no hair is between the skin and the facepiece sealing surface.

-

Figure 5.47 A firefighter pulling the protective hood into place around the SCBA facepiece. Center the chin in the chin cup and the harness at the rear of the head.

- Tighten the facepiece straps by pulling opposing straps evenly and simultaneously to the rear. (Figure 5.46).

- Pulling the straps outward, to the sides, may damage them and prevent proper engagement with the adjusting buckles. Tighten the lower straps first, then the temple straps, and finally the top strap, if there is one.

- Always check that the facepiece is completely sealed to the face, the exhalation valve is functioning, and all connections are secure. If there is a donning mode switch, check that it is in the proper position.

- Ensure that the protective hood is over the facepiece harness or straps. Also ensure that the hood is covering all exposed skin, that your vision is not obscured, and that no portion of the hood is between the facepiece and your face (Figure 5.47).

- Wear the helmet with the chin straps secured (Figure 5.48). Adjust helmets equipped with a ratchet adjustment so that the helmet fits properly.

Doffing Protective Breathing Apparatus

Doffing (removal) techniques differ for the different types of SCBA.However, the following actions apply when doffing any brand or model:

- Make sure you are out of the contaminated area and that the SCBA is no longer required.

- Discontinue the flow of air from the regulator to the facepiece.

- Disconnect the regulator from the facepiece and secure it.

- Remove the protective hood or pull it down around your neck.

- Remove the facepiece by loosening the straps and lifting it from your chin.

- Remove the backpack assembly while protecting the regulator.

- Close the cylinder valve.

- Relieve pressure from the regulator according to the manufacturer’s instructions.

- Turn off the PASS device and/or control module.

- Extend all facepiece and harness straps.

- Check air pressure to determine if the air cylinder needs to be refilled or replaced.

- Clean and disinfect the facepiece.

- Clean the SCBA backplate and harness if necessary.

- Secure the complete unit in its case, seat bracket, or storage bracket.

Skill Sheet 5-4 describes the steps for doffing personal protective equipment and SCBA and preparing them for reuse.

Inspection and Maintenance ofSCBA

NFPA 1852 establishes the frequency of SCBA inspections. Firefighters inspect their SCBA on a schedule that their department determines and one that is based on NFPA, OSHA, and manufacturer requirements. Inspections are typically performed daily, weekly, or whenever firefighters report for duty. The period between inspections must not exceed one week. Qualified SCBA repair technicians must inspect the units annually and after any repairs have been completed.

SCBA Inspection and Care

Your SCBA requires ongoing inspection and maintenance to protect you properly.

You must clean and inspect it:

- After each use

- At the start of every duty shift

- Every week

If repairs are necessary, report this immediately. Extensive repairs and cleaning may require that the unit be taken out of service and replaced by a reserve unit. Skill Sheet 5-5 describes the steps for inspecting an SCBA.

SCBA Inspections Each fire department should establish a daily/weekly SCBA inspection policy and program.

A daily/weekly inspection should include the following SCBA components:

- Facepiece (Figure 5.49)

- Breathing air cylinder assembly

- Low-pressure alarm

- Pressure indicator gauges

- Backplate and harness assembly

- Hoses (Figure 5.50)

- Regulator

- Integrated PASS

These inspections can help identify wear and tear, damage, and potential problems before they result in failure during an emergency. SCBA inspections should be documented to record the findings, report problems, and show trends.

**NOTE: During the inspection, the inspector should check the hydrostatic test date label on the air cylinder to see if the cylinder is due for hydrostatic testing to check for flaws and leaks (Figure 5.51).**

SCBA Care

You should clean and sanitize the SCBA facepiece after each use toprevent debris from collecting in the exhalation valve and regulator fitting. Dirt or other foreign materials can cause the exhalation valve to malfunction and allow cylinder air to escape, depleting the air supply. Debris can also prevent the regulator from fitting securely to the facepiece. Soot and scratches on the facepiece lens can reduce visibility.

Wash the facepiece thoroughly with warm water containing a mild commercial disinfectant and then rinse with clear, warm water. After cleaning, take special care to ensure proper operation of the exhalation valve. If it does not operate correctly, either repeat cleaning to identify the problem or report the facepiece as damagedand out-of-service. Dry the facepiece with a lint-free cloth or air dry it (Figure 5.52). Do not use paper towels to dry the facepiece because they will scratch the facepiece lens. There is also specialized respiratory drying equipment that can be used if available.

Although facepieces are impact-resistant, they scratch easily. You must not submerge regulators and low-pressure hoses in water for cleaning. Sanitize the facepiece seal and interior of the facepiece to prevent you from inhaling or coming in contact with contaminants, especially if you share the facepiece with other personnel. Refer to the manufacturer’s instructions on proper facepiece care and maintenance.

Facepiece lenses can also fog up internally due to the difference between the inside and outside temperatures or a defective or missing nose cup. To prevent fogging, some SCBA facepieces are permanently treated with an antifogging chemical. Special antifogging chemicals that the manufacturer recommends can also be applied to the facepiece lens following cleaning.

Many departments issue each firefighter an individual facepiece that is not shared with other firefighters. This

eliminates the risk of spreading germs from one wearer to the next and ensures that the mask is the correct size, providing a complete seal. Even if you are assigned your own facepiece, clean it after each use. After the facepiece is clean and dry, store it in a case, a bag, or coat pocket. Leave the facepiece straps fully extended to facilitate donning. Skill Sheet 5-6 shows the procedures for cleaning and sanitizing an SCBA.

Lesson 6

Outcomes:

- Explain the process of inspecting and cleaning SCBA.

Annual SCBA Inspection and Maintenance

In accordance with the manufacturer’s recommendations, specially trained, factory-qualified technicians must perform annual inspections and maintenance. These technicians may be trained fire department personnel or certified maintenance contractor employees.

Refilling SCBA Cylinders

Firefighters may use three breathing air sources to refill depleted SCBA air cylinders:

- Stationary fill systems— Systems installed at stations

- Mobile fill systems— Systems mounted on apparatus or trailers

- Firefighter Breathing Air Replenishment Systems (FBARS) — Systems installed inhigh-rise buildings; might also be referred to as a Firefighter Air Replenishment Systems (FFARs).

Each source must provide Type 1 Grade D quality air, as specified by OSHA and Canadian government requirements. Skill Sheet 5-7 provides procedures for filling an SCBA cylinder from a cascade system and for filling an SCBA cylinder from a compressor/purifier. The following safety precautions apply when refilling an SCBA cylinder:

- Check the hydrostatic test date of the cylinder.

- Perform the required inspection of cylinders before filling.

- Check the working pressure.

- Wear the required hearing and eye protection during fill operations

- Place the cylinder in a shielded fill station.

- Fill the cylinder slowly to prevent it from overheating.

- Ensure that the cylinder is completely full but not over-pressurized (overfilled).

- Only allow trained personnel to operate the fill equipment.

Filling unshielded cylinders while a firefighter is wearing the SCBA is prohibited. However, a rapid intervention crew (RIC) rescuing a trapped or incapacitated firefighter may be granted an exception to this rule.

The following criteria must be met before filling a worn SCBA:

- NIOSH-approved RIC Universal Air Connection (UAC) fill options are used.

- A risk assessment has been conducted to limit safety hazards and ensure that necessary equipment is fully operational.

- There is an imminent threat to the safety of the downed firefighter, and immediate action is required to prevent loss of life or serious injury.

Stationary Fill Stations

SCBA breathing air cylinders are filled from a cascade system or directly from a compressor air purification system (Figure 5.53). Both systems connect to a fill station that holds the SCBA cylinders in rupture-proof sleeves during the filling process. If your department fills its own SCBA cylinders, you will receive training on how to safely use the system. Some departments do not fill their own cylinders and contract the process out to a qualified breathing air supplier. Filling procedures should be posted on the fill station and must follow the fill station manufacturer’s recommendations to avoid excessive overheating in the cylinder.

A third-party testing facility must regularly test breathing air, and the department must document the testing results. The department’s health and safety officer is usually responsible for monitoring the testing and maintaining the documentation.

Auto-Cascade System

A type of stationary fill station that is completely automated. When firefighters properly place cylinders in the system, the system opens and closes valves automatically to complete the fill process. Auto-cascade systems fill cylinders to a programmable desired pressure. These systems may be retrofitted to existing, manual cascade systems as add-on modules.

Mobile Fill Systems

Mobile breathing air fill systems are designed to refill air cylinders at emergency incidents. They typically consist of a fill station equipped with a breathing-air compressor or cascade fill station and are mounted on a trailer or the apparatus chassis (Figure 5.54).

System operations are similar to the stationary systems previously mentioned. The system may also be designed to support a supplied air respirator (SAR) system or a firefighter breathing air replenishment system (FBARS) installed in a high-rise structure

Firefighter Breathing Air Replenishment Systems (FBARS)

To fight high-rise fires more effectively and avoid the need to carry many full SCBA cylinders to upper floors, fire departments needed a better way to refill SCBA cylinders on upper floors. To solve this problem, many municipalities now require that all newly constructed buildings taller than 75 feet (25 m) install FBARS (Figure 5.55). FBARS provides an endless source of breathing air to any floor within the structure from a ground-level connection.

These systems typically consist of:

- A fire department air connection panel, containing connection fittings, control valves, and gauges, located on the exterior of the structure

- An Emergency Air Storage (EAS) system that provides breathing air if a mobile system is not available to supply the external connection

- Remote air fill panels, containing a certified rupture-proof containment fill station, connection and control valves, and gauges, located in protected stairwells on specific floors

- Interconnected piping certified to carry breathing air under pressure throughout the system

- Low air pressure monitoring switches and alarms, used to maintain minimum air pressure and warn of pressure loss or system failure