10 Chapter 9: Forcible Entry

Welcome! Tansi!

Essentials of Firefighting

Chapter Objectives

- Describe the basic principles of forcible entry. [4.3.4, 4.3.11]

- Describe forcible entry tools. [4.3.4, 4.3.9]

- Explain considerations for forcible entry tool safety. [4.3.4]

- Explain how to carry forcible entry tools. [4.3.4]

- Describe how to clean and maintain forcible entry tools. [4.5.1]

- Describe methods of forcing entry through doors. [4.3.4, 4.3.9, 4.3.11]

- Describe methods for forcing entry through windows. [4.3.4, 4.3.9, 4.3.11]

- Describe methods for breaching walls. [4.3.4, 4.3.9]

- Skill Sheet 9-1: Clean, inspect, and maintain hand tools and equipment. [4.5.1]

- Skill Sheet 9-2: Force entry through an inward-swinging door. [4.3.4]

- Skill Sheet 9-3: Force entry through an outward-swinging door. [4.3.4]

- Skill Sheet 9-4: Force entry through a door lock. [4.3.4]

- Skill Sheet 9-5: Force entry through a padlock. [4.3.4]

- Skill Sheet 9-6: Force entry through a window. [4.3.4, 4.3.11]

- Skill Sheet 9-7: Force entry through a wood-framed wall (Type V construction). [4.3.4]

- Skill Sheet 9-8: Breach a masonry wall with hand tools. [4.3.4]

- Skill Sheet 9-9: Breach a metal wall with a rotary saw. [4.3.4]

Gaining access to a structure can require firefighters to force locks, doors, windows, or other barriers. The sooner that entry can be made, the faster firefighters can control the emergency. Forcible entry requires knowledge of building construction, fire behaviour, and property conservation. To gain entry, firefighters must use the correct location and the proper technique. Effective size-up and situational awareness are essential during forcible entry. The many tools used for structural forcible entry operations are identified in this chapter as well as their proper use, care, and maintenance. Also described are the characteristics of various types of barriers that firefighters may face to gain access to buildings during fires or other emergencies.

Now, what?

Let’s get learning!

Lesson 1

Outcomes:

- Describe the basic principles of forcible entry.

Basic Principles of Forcible Entry

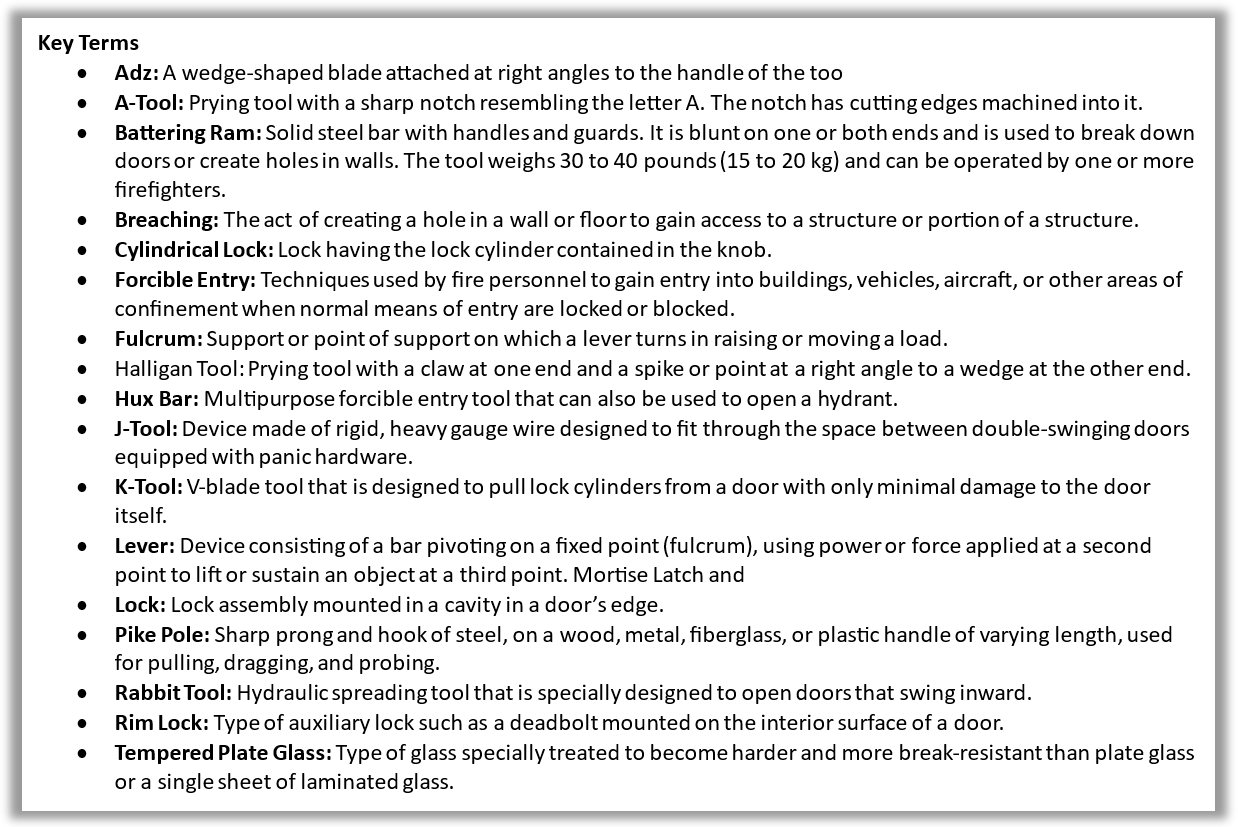

Forcible entry refers to the techniques used to gain access into a compartment, structure, facility, or site when the normal means of entry is locked or blocked. Forcible entry techniques do minimal damage to the structure or structural components and provide quick access to the emergency. Do not use forcible entry when normal means of access are available.

These techniques can also be applied to:

- Vehicles

- Aircraft

- Railway passenger cars

- Ships

The Incident Commander (IC) or your supervisor will determine where to force entry based upon the following factors:

- Tactics that must be fulfilled

- Stage of the fire

- Location of the fire or hazard

- Effect on ventilation

- Effort required to force entry

**NOTE: Wait to be ordered to force entry before doing so. **

It may be easier to force a basement window to apply water on a fire than to force entry through a door and advance a hoseline down an interior stairway. The location of an opening that adds fresh air to a ventilation-controlled fire can drastically affect fire behaviour. Any entry into a structure is a form of ventilation, allowing an exchange of fresh air and products of combustion. Control doors and windows to limit the amount of fresh air entering the structure which can intensify the fire.

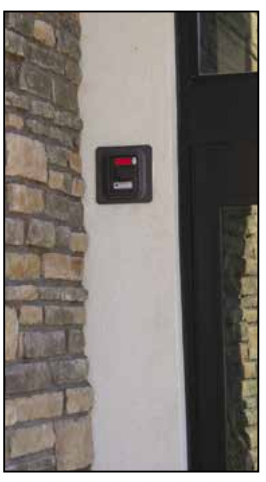

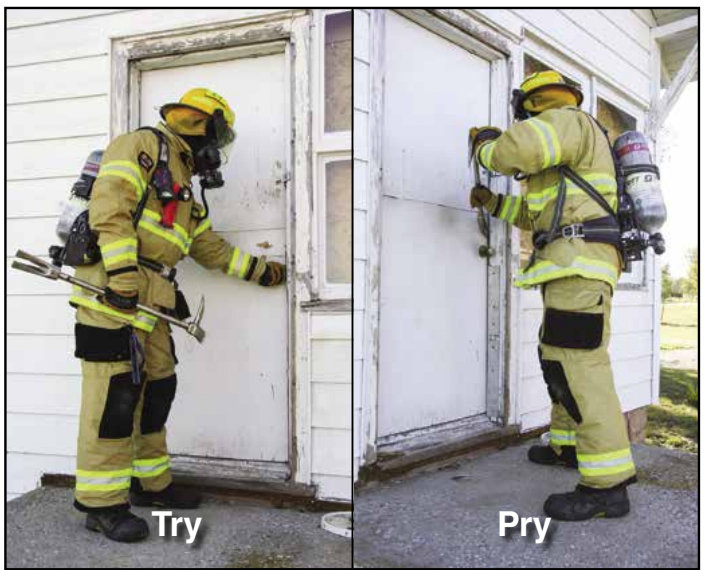

At every door or window, remember to first “try before you pry” (Figure 9.1).

- The door or window may be unlocked and can be opened in a normal manner.

- Look for a lock box near the main entrance – Especially in commercial and industrial occupancies. (Figure 9.2).

- Using a door key or numeric keypad combination from inside a lock box reduces property damage and may allow quicker entry.

- Lockbox information may be stored in building preincident plans and/or computer-aided dispatch (CAD) data to speed access during incident operations.

General considerations for forcible entry:

- Doors and locks

Construction, direction of opening (inward or outward), type of frame, type of lock, and mounting of the lock. - Proper tools

Knowing and using the correct tools needed to do a particular job; adjusting entry activity based upon available tools. - Security barriersCould include bars, grilles, Lexan® windows, and others; require specialized training, tools, and knowledge to force; block escape routes for both firefighters and occupants; may necessitate making multiple openings for entry (Figure 9.3).

**NOTE: The tools described in this chapter are not intended to be a comprehensive list of all tools that may be available. **

Lesson 2

Outcomes:

- Describe forcible entry tools.

- Explain considerations for forcible entry tool safety.

- Explain how to carry forcible entry tools.

- Describe how to clean and maintain forcible entry tools.

Forcible Entry Tools

Firefighters must know the capabilities and limitations of the forcible entry tools available to them. Selecting the proper tool can make all the difference in overcoming a barrier. This section describes the various forcible entry tools and provides information on their use, care, and maintenance. When using any forcible entry tools, always wear appropriate personal protective equipment (PPE), especially hand, eye, and hearing protection.

Forcible entry tools can be divided into four basic categories:

- Cutting tools

- Prying tools

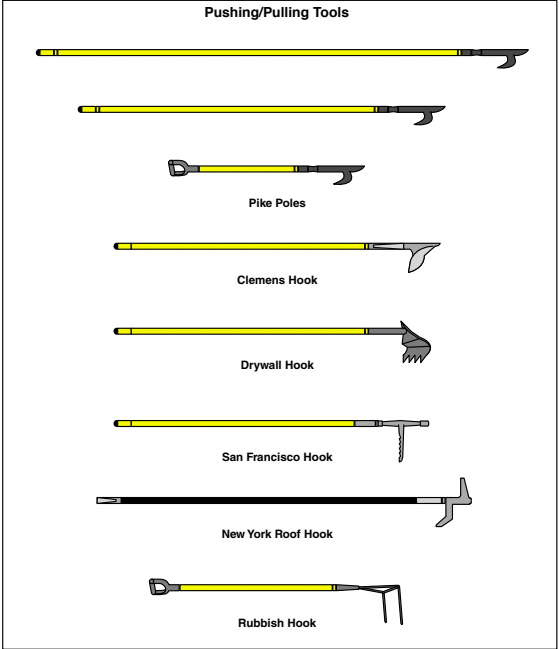

- Pushing/pulling tools

- Striking tools

- Cutting Tools

Cutting tools can be powered manually or with another power source. These tools are often specific to the types of materials they can cut and how fast they can cut them. No single cutting tool will safely and efficiently cut all materials. Using a cutting tool on materials for which it was not designed can damage the tool and endanger the operator.

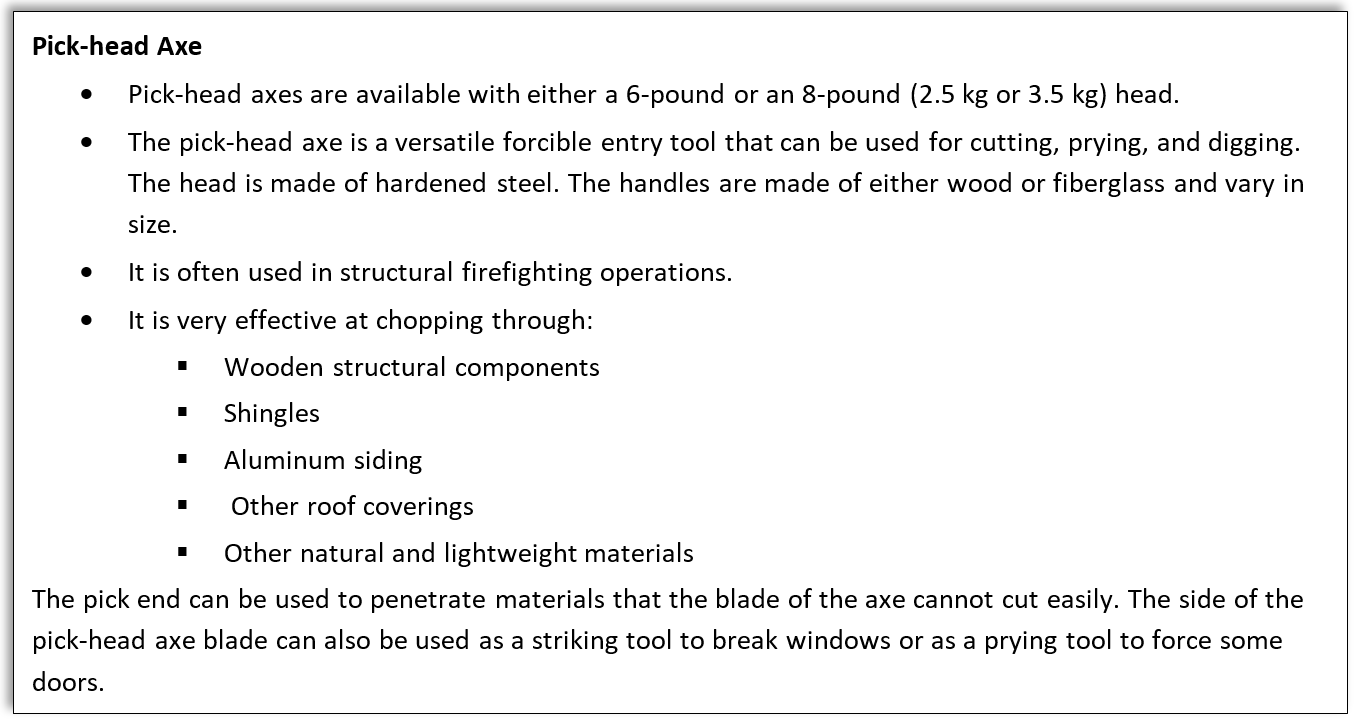

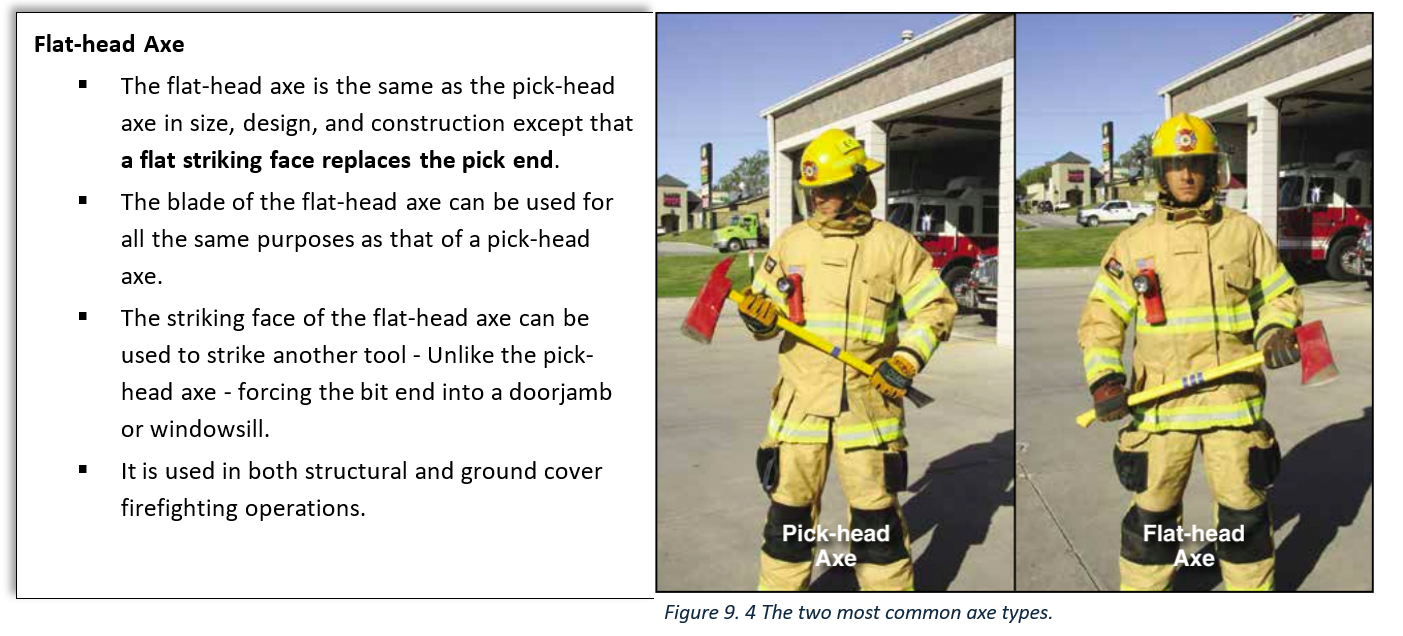

Axes

- Axes are the most common types of cutting tools used by firefighters.

- The two basic types of axes are the pick-head axe and the flat-head axe (Figure 9.4).

- Smaller axes and hatchets may be used in salvage and overhaul operations, but they are usually too lightweight and inefficient for effective use in forcible entry operations.

Metal Cutting Device

Metal cutting devices are used to cut through heavy-duty locks, metal-clad doors, window security bars and grilles, and similar items.

- The devices include:

- Bolt cutters

- Cutting torches

- Manual or powered rebar cutters

Bolt Cutters

Bolt cutters are used to cut (Figure 9.5):

- Iron bars

- Cables

- Chains

- Bolts

- Pins

- Hasps

- Some padlock shackles

Manual bolt cutters are less effective than they once were because they cannot cut modern high-security chains, hasps, and padlock shackles. These materials shatter the bolt cutter blades or cause the handles to fail under the tremendous pressure that the operator exerts. Some other locks are designed to prevent bolt cutters from being inserted into the shackle.

Do not use bolt cutters to cut case-hardened materials found in locks and other security devices. When using bolt cutters, always wear face shields and eye protection to prevent fragments of the cut material from striking your face. Do not use bolt cutters to cut any energized cables unless the cutters are insulated and designed for that task.

Cutting Torches

A cutting torch may be used to cut:

- Security bars

- Gates

- Grilles

- Hinges

- Rebar

Firefighters commonly use:

- Oxyacetylene cutting torches (Figure 9.6)

- Oxygasoline cutting torches

- Burning bars

- Plasma cutters

Figure 9. 7 A firefighter using a rebar cutter to cut security bars during a training exercise.

Training based on the manufacturer’s recommendations specific to each cutting and burning device is necessary for safe and efficient operation. A charged hoseline must be in place during the cutting operation to cool the metal and control any sparks that are generated.

Do not use cutting torches in or near a flammable or explosive environment. Sparks, the exposed flame of the torch, or hot fragments (slag) can ignite a fire or cause an explosion.

Rebar cutters

These hydraulic cutting tools are available in both powered and manual versions. The manual

version requires more energy to use but can be used in areas beyond the reach of the hydraulic supply hose on powered units. Firefighters can use rebar cutters to cut steel reinforced bars (rebar) in concrete walls or to cut door or window security bars (Figure 9.7).

![]()

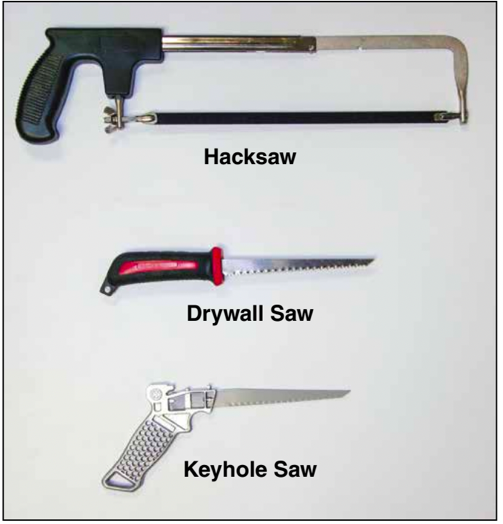

Handsaws

Handsaws may be useful when power saws are not available or the workspace around the location of the cut is limited. Hacksaws, drywall saws, and keyhole saws are the most common handsaws still in use (Figure 9.8). Firefighters should know which saw is best suited to their current job and should use good handsaw technique.

Power Saws

Power saws commonly used in the fire service include (Figure 9.9):

- Circular saw

- Rotary saw

- Reciprocating saw

- Chain saw

Power sources may be a self-contained battery pack, gasoline engine, or electricity from a generator or electrical outlet. You should be familiar with the saws that your department uses. When operating power saws, always follow both the manufacturer’s recommendations and departmental SOPs.

When operating any power saw, always use eye, hearing, and hand protection. Forcing the saw (or any tool) beyond its design limitations can result in property damage and/or injury to the operator. Never use a power saw in a flammable atmosphere. The saw’s motor or sparks from the cutting operation can ignite a fire or cause an explosion.

When operating any power saw, always use eye, hearing, and hand protection. Forcing the saw (or any tool) beyond its design limitations can result in property damage and/or injury to the operator. Never use a power saw in a flammable atmosphere. The saw’s motor or sparks from the cutting operation can ignite a fire or cause an explosion.

Circular Saw

- This saw is especially useful in situations where electrical power is readily available, and heavier and bulkier power saws are too difficult to handle.

- Small battery-powered units are also available.

- They have many firefighting, rescue, and overhaul applications.

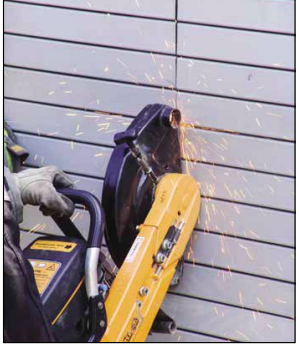

Rotary Saw

- Rotary saws used in the fire service are usually gasoline powered with changeable blades available for cutting wood, metal, and masonry.

- When using a rotary saw to cut metal, have a charged hoseline or portable fire extinguisher nearby due to the sparks produced from it.

- Depending upon the type of rotary saw, the blades may spin at more than 6,000 rpm.

- Blades range from large-toothed blades for quick rough cuts to those with fine teeth for a more precise cut.

- Some blades are made specifically for cutting metal or concrete.

- Saw blades with carbide-tipped teeth are superior to standard blades because they are less prone to dulling after heavy use.

Reciprocating Saw

- The reciprocating saw is very powerful, versatile, and easy to control.

- It has a short, straight blade that moves in and out with an action like that of a handsaw.

- It can use a variety of blades for cutting different materials.

- When equipped with a metal-cutting blade, this saw is ideal for cutting sheet metal body panels and structural components on vehicles as well as metal doors and wall panels in structures.

Chainsaw

- Chainsaws are commonly used for forcible entry, ventilation, rescue, and overhaul operations.

- They can be powered by gasoline engines, electricity, compressed air, or hydraulic power.

- Cutting chains come in a variety of types for use in cutting building materials such as:

- Wood

- Stone

- Concrete

- Brick

- They are useful for clearing downed trees and limbs from streets and access routes after natural disasters, such as tornadoes and ice storms.

- they are also used to cut structural collapse debris to free trapped victims.

- Chainsaws should be equipped with kickback protection and chain brakes for safety as well as carbide-tipped chains and depth gauges for better saw control.

Prying Tools

Prying tools are useful for:

- Opening doors

- Opening locks

- Opening windows

- Moving heavy objects

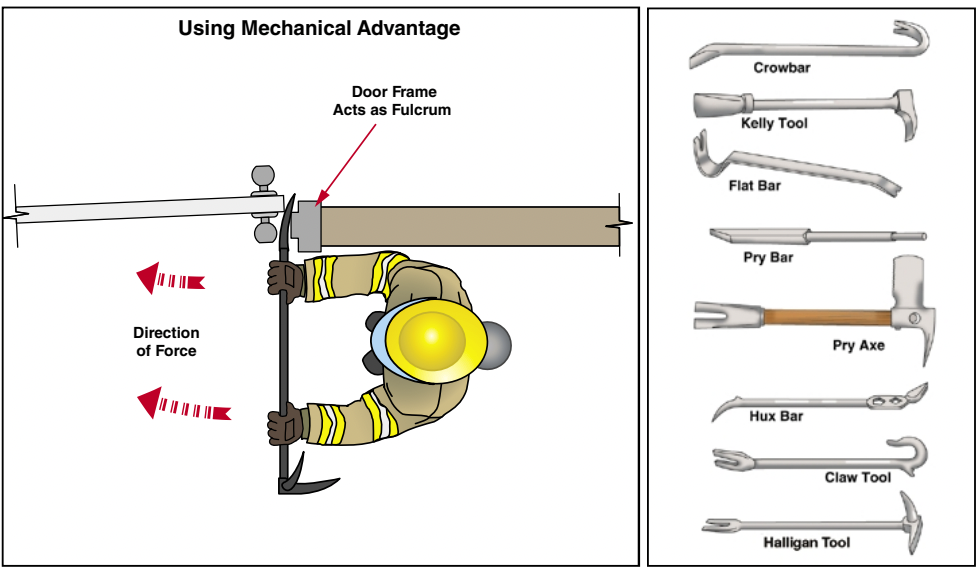

A prying tool uses the principles of a lever and a fulcrum to force entry through a door.

Pry bars and other manually operated prying tools use the principle of the lever and fulcrum to provide a mechanical advantage (Figure 9.10). Force applied to the tool’s handle is multiplied at the working end based on the distance between the fulcrum and the working end. The longer the handle is, the greater the force produced at the working end.

Manual Prying Tools

The most common manual prying tools used in the fire service are as follows (Figure 9.11):

- Crowbar

- Pry (pinch) bar

- Claw tool

- Pry axe

- Halligan tool

- Hux bar

- Kelly tool

- Flat bar (nail puller)

- Rambar

Most manual pry tools are constructed from single-piece high-carbon steel, approximately 30 to 36 inches (760 to 900 mm) in length. These tools usually have one end that is bevelled into a single wedge or fork. The opposite end of the tool may include a hook, pike tip, or adz. A rambar has a sliding weight on the shaft that is used to drive the wedge or fork into an opening. Miniature versions of manual pry tools are also available and have accompanying sheaths for carrying the tool.

Some prying tools can also be used effectively as striking tools, although most cannot. You need to be familiar with the capabilities and limitations of each manual prying tool, such as knowing which surfaces are used for prying and which surfaces may be used for striking.

Hydraulic Prying Tools

Hydraulic prying tools receive their power from hydraulic fluid pumped through special high-pressure hoses. The pumping mechanism can be either powered or manual. Although compressed air is sometimes used to power hydraulic pumps, electric motors or two- or four-cycle gasoline engines are much more common. Manual hydraulic tools require more labour to operate and operate more slowly than powered hydraulic tools; however, they are usually smaller, lighter, and easier to carry.

Hydraulic prying tools that one person can operate have proven to be very effective for forcible entry and extrication operations. These tools can be used in a variety of different operations involving prying, pushing, or pulling. The rescue tools and hydraulic door opener are examples of hydraulic prying tools.

Rescue Tools

- Hydraulic spreaders and hydraulic rams usually associated with vehicle extrication have some uses in forcible entry.

- Hydraulic spreaders can exert force either to spread something apart or to pull heavy objects (Figure 9.12)

Hydraulic Rams

- They also have spreading capabilities and can be used for pushing and pulling.

- In forcible entry, place hydraulic rams inside a doorframe and use the rams to spread the frame far enough apart for the door to swing open.

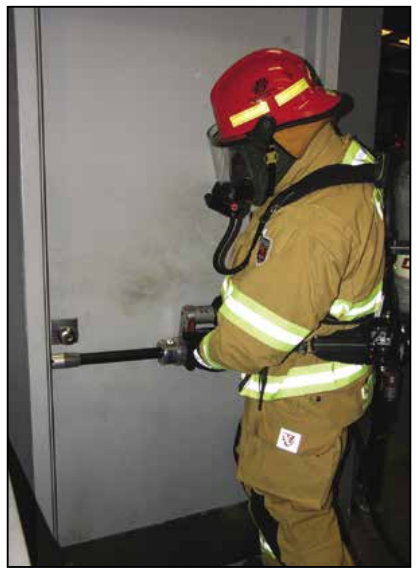

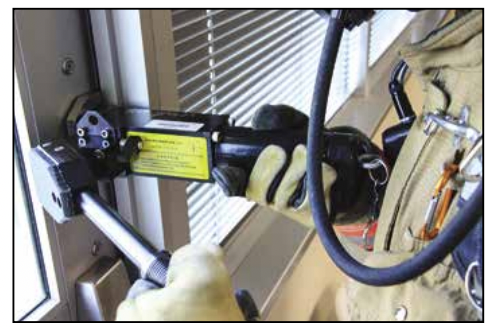

Hydraulic Door Opener

- This opener is manually operated, relatively lightweight and consists of a hand pump and spreader device.

- The spreader has intermeshed teeth that can be easily slipped into a narrow opening such as between a door and doorframe.

- A few pumps of the handle cause the jaws of the spreader device to open, exerting pressure on the object to be moved (Figure 9.13).

- The pressure usually causes the locking mechanism or door to fail.

- These are extremely valuable tools when more than one door must be forced, such as in apartments or hotels.

Pushing/Pulling Tools

Pushing and pulling tools have limited use in forcible entry, but in certain instances, such as breaking glass and opening walls or ceilings, they are the tools of choice.

This category of tools includes the following (Figure 9.14):

- Pike pole

- Plaster hook

- San Francisco hook

- Roofman’s hook

- Clemens hook

- Drywall hook

- Multipurpose hook

- Rubbish hook

- New York Roof Hook

Pike poles and Hooks

- Are available in various lengths, giving firefighters a reach advantage when performing certain tasks.

- The plaster hook has two knifelike wings that depress as the head is driven through a ceiling or other obstruction and reopens or spreads outward under the pressure of self-contained springs.

- Use pike poles and hooks (except for the all-metal, roof man’s hook) only for pushing or pulling, never prying. If a lever is needed, select the appropriate prying tool.

- Handles of pike poles and hooks are made of wood or fibreglass and may break if used as a lever.

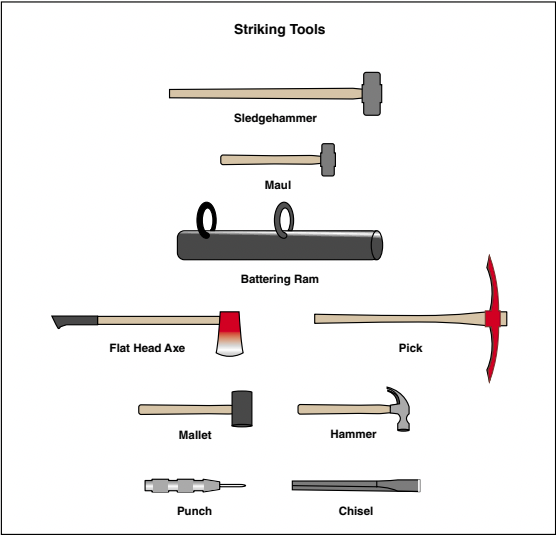

Striking Tools

A striking tool is a very basic hand tool consisting of a weighted head attached to a handle.

The following are examples of common striking tools (Figure 9.15):

- Sledgehammer (8, 10, and 16 pounds [3.5, 4.5, and 7.5 kg])

- Maul

- Battering ram

- Pick

- Flat-head axe

- Mallet

- Hammer

- Punch

- Chisel

In some cases, a striking tool is the only tool required. In other situations, the striking tool is used with another tool to gain entry. When striking tools are dropped or used improperly, they can crush fingers, toes, and other body parts. Poorly maintained striking surfaces may cause metal chips or splinters to fly into the air. Therefore, proper eye protection (safety glasses or goggles in addition to the helmet face shield) must be worn when using striking tools.

The Battering Ram

The battering ram is used to make openings in walls and force doors. The battering ram weighs 30 to 40 pounds (15 to 20 kg) and is made of steel with installed handles and hand guards. One end is forked for breaking ordinary brick and concrete blocks, and the other end is rounded and smooth for battering doors and other types of walls. One to four firefighters holding the attached handles can swing the ram back and forth into a wall or door to create a breach.

Tools Used in Combination

There is no single forcible entry tool that provides the firefighter with the needed force or leverage to handle all forcible entry situations. In some cases, firefighters must combine two or more tools to accomplish a task. Two common tools used in combination for forcible entry are the flat-head axe and the Halligan tool, a combination of tools known as “irons.” The types of tool combinations carried vary, depending on building construction, security concerns, tool availability, and other factors within a fire department and the area served.

The primary factor to consider is selecting the appropriate tools to do the job. Using tools in situations for which they are not designed can be extremely dangerous. Pre-incident surveys will help determine which tools will be required to force entry into a particular building or through a particular door, window, or wall in that building.

Tool Safety

Improper use of power and hand tools can result in:

- Strains

- Sprains

- Fractures

- Abrasions

- Lacerations

To prevent these injuries, you must:

- Wear appropriate PPE; additional PPE may be required depending on the incident.

- Use only undamaged tools.

- Select the right tool for the type of opening to be made.

- Use tools for their intended purpose only.

- Position yourself so that your weight is balanced on both feet.

- Ensure that you have room to operate the tool properly.

- Be aware that there will be a sudden release of energy when the door, window, or wall is opened.

- Ensure that other personnel are out of the immediate area.

- Be aware of the environment to prevent possible gas or vapour ignitions.

You must become familiar with all the tools you will use, which includes reading and following all the manufacturer’s guidelines as well as your department’s SOPs on tool safety. When tools are not in use, they should be kept in properly designated places on the apparatus. Check the location of tools carried on the apparatus and make sure they are secured in their brackets. Repair or replace damaged tools immediately.

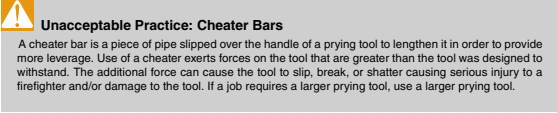

As with other tools, using prying tools incorrectly creates a safety hazard. If a job cannot be completed with a particular tool, do not strike the handle of the tool; use a larger tool. Also, do not use a prying tool as a striking tool unless it has been designed for that purpose.

To prevent injury, use extreme care with rotary saws, power saws, and chain saws as follows:

- Match the saw and saw blades to the task and material to be cut.

- Never force a saw beyond its design limitations.

- Always wear full PPE, including gloves, hearing protection, and eye protection (Figure 9.16).

- Fully inspect the saw before and after use.

- Do not use any power saw when working in a flammable atmosphere or near flammable liquids.

- Maintain situational awareness.

- Keep unprotected and nonessential people out of the work area.

- Follow the manufacturer’s guidelines for proper saw operation.

- Keep blades and chains sharpened. A dull saw is more likely to cause an accident than a sharp one.

- Be aware of hidden hazards such as electrical wires, gas lines, and water lines.

- Remember that the rotating blade on a rotary saw continues to spin after the throttle has been released.

- Use only blades that are manufacturer-approved for your saw; blades from different manufacturers may not be interchangeable.

- When making cuts, account for the twisting (gyroscopic or torsion effect) of a rotary saw blade to maintain control of the saw.

- Start all cuts at full revolutions per minute (rpm) to prevent the blades from binding into the material.

- Store blades in a clean, dry environment.

Store composite blades in compartments where gasoline fumes will not accumulate because hydrocarbons can attack the bonding material in these blades causing them to deteriorate and violently shatter during use.

Carrying Tools

You must carry forcible entry tools in the safest manner possible to protect yourself, other firefighters, and by-standers. When lifting heavy tools or other objects, always lift with your legs and not your back. Get help when transporting heavy tools. Avoid running with tools.

Some recommended safety practices for carrying specific tools are as follows (Figure 9.17):

- Axes: If not in a scabbard, carry the axe with the blade away from the body. With pick-head axes, grasp the pick with a hand to cover it. Never carry an axe on the shoulder.

- Prying tools: Carry these tools with any pointed or sharp edges away from the body. This can be difficult when carrying tools with multiple cutting or prying surfaces such as a bit on one end and an adz on the other.

- Combinations of tools: Strap tool combinations together. Halligan tools and flat-head axes can be nested together and strapped.

- Pike poles and hooks: Carry these tools with the tool head down, close to the ground, and ahead of the body when outside a structure. When entering a building, carefully reposition the tool and carry it with the head upright close to the body to facilitate prompt use. These tools are especially dangerous because they are somewhat unwieldy and can severely injure anyone accidentally jabbed with the working end of the tool.

- Striking tools: Keep the heads of these tools close to the ground. Maintain a firm grip. Mauls and sledge-hammers are heavy and may slip from your grasp.

- Power tools: Never carry a power tool that is operating more than 10 feet (3 m); running power tools are potentially lethal weapons. Transport the tool to the area where the work will be performed and start it there. Carry the saw with the blade forward and toward the ground. To prevent fuel from leaking, ensure that the gas cap is tight and the gasket is in place.

Care and Maintenance of Forcible Entry Tools

Forcible entry tools will function as designed if they are properly maintained and kept in the best condition. Tool failure at an emergency incident can result in potentially harmful delays as well as severe injury or death. Always read the manufacturer’s recommended maintenance guidelines for all tools, especially power tools. Follow your department’s procedures to report any tools or equipment that need repairs. Tools that are damaged or excessively worn should be removed from service, tagged, and sent to the proper authority for repair or replacement.

The sections that follow describe some basic maintenance procedures for various forcible entry tools. Refer to Skill Sheet 9-1 for procedures for cleaning, inspecting, and maintaining hand tools and equipment.

** NOTE: The procedures for cleaning, inspecting, and maintaining power tools are covered as a Fire Fighter II skill in Chapter 21, Maintenance and Testing Responsibilities to coincide with NFPA 1001. Personnel in departments that require the Fire Fighter I to maintain power equipment may refer to that chapter. **

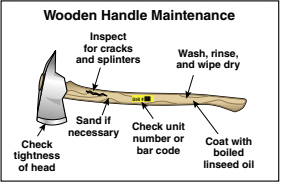

Wooden Handles

Care and maintenance of wooden handles includes:

- Inspecting the handle for cracks, blisters, or splinters (Figure 9.18).

- Sanding the handle if necessary to eliminate splinters.

- Washing the handle with mild detergent, rinsing, and wiping dry. Do not soak the handle in water because it will cause the wood to swell.

- Applying a coat of boiled linseed oil to the handle to preserve it and prevent roughness and warping. Do not paint or varnish the handle.

- Checking the tightness of the tool head.

- Limiting the amount of surface area used for tool marking. Unit designations can be applied on strips of tape or self-adhesive barcodes on the handle.

After applying linseed oil, use detergent and water to hand wash the oil-coated rags used to clean wooden handles. Lay the rinsed materials flat until they are dried completely. After drying, dispose of the cleaning materials.

Fiberglass Handles

Fibreglass handles are easier to maintain than wood handles. Care includes:

- Washing the handle with mild detergent, rinsing, and wiping dry

- Checking for damage or cracks

- Checking the tightness of the tool head

Cutting Edges

Cutting edges on axes requires the following care and maintenance:

- Inspecting the cutting edge for chips, cracks, or spurs (Figure 9.19).

- Replacing axe head when required.

- Filing the cutting edges by hand; grinding weakens the tool.

- Sharpening the blade as specified in departmental SOPs.

How well an axe head is maintained directly affects how well it will perform. If the blade is extremely sharp and ground too thin, pieces of the blade may break when cutting gravel roofs or striking nails and/or screws in doors, walls, roof decking, or flooring. If the blade is too thick, regardless of its sharpness, it is difficult to drive the axe head through ordinary objects.

**NOTE: Never apply paint to the cutting surface of an axe head; this may cause the cutting surface to stick and bind.**

Plated Surfaces

Protection of plated surfaces comes from chromium or an electro-plating process that applies another metal. Either wipe plated surfaces clean or wash them using mild detergent and water. Rinse and then wipe dry. Inspect these surfaces for damage.

Unprotected Metal Surfaces

Unprotected metal surfaces are the blades, wedges, pikes, handles, and other tool components that have not been electroplated to protect them from corrosion.

Instructions for care are as follows:

- Use an emery cloth or steel wool to remove dirt and rust (Figure 9.20).

- Use a metal file to remove burrs from the cutting edge and body.

- Do not make the blade edge too sharp; this may cause the blade to chip or break.

Do not use a mechanical grinder to sharpen the blade edge because it may cause a loss of temper through overheating. - Oil the metal surface lightly. Light machine oil works best. Avoid using any metal protectant that contains 1-1-1-trichloroethane. This chemical may damage and weaken the handle.

- Do not apply oil to the striking surface of tools.

- Do not paint metal surfaces — paint hides defects.

- Inspect the metal for chips, cracks, burrs, or sharp edges, and file them off when found.

Lesson 3

Outcomes:

- Describe methods of forcing entry through doors.

Forcing Entry Through Doors

Forcing entry through doors is the most conventional method used in the fire service. A firefighter can perform forcible entry, if necessary, once he or she has sized up a door. Determining the type of forcible entry to use depends on the firefighter’s knowledge of door construction (see Chapter 3, Building Construction) and locks (described in this chapter.)

Consider the amount of damage that will result from forcible entry. For example, destroying or removing the door during forcible entry eliminates the ability to open and close it to maintain door control. Consider the following ways to reduce the amount of damage that will result from forcible entry:

- Begin the decision-making process with the minimum amount of damage and proceed to the maximum amount.

- Determine the severity of the emergency and the speed with which entry must be gained.

- Try to open the door in the normal fashion. If that does not work, look for a lock box. A lock box may contain a key or means of opening the door.

- Look for a door window or side light panel that you can break to provide access to the lock on the interior.

- Determine if it is quicker to (Figure 9.21):

- Force the lock.

- Remove hinge pins.

- Force the door.

- Pry the door from the jamb.

Rapid-entry lockbox systems provide a means to open locked doors without forcing entry because the lock box holds all necessary keys or numeric keypad combinations to unlock the building, storage areas, gates, and elevators. The lock box is mounted at a high-visibility location on the building’s exterior (Figure 9.22). Unauthorized duplication of the master key is prevented because the special key blanks are not available to locksmiths and cannot be duplicated with conventional equipment. Only the fire department possesses a master key that opens all boxes in its jurisdiction.

During forcible entry, it is critical to maintain control of the door. The structure’s ventilation profile will change if you open a door, and it may have an adverse effect on fire behaviour. If the door is damaged to the point that it cannot be closed, take steps to deal with subsequent changes in fire behaviour. Station a firefighter at the door to maintain control of the door to block the flow path from the exterior and control airflow into the structure during interior firefighting operations. This firefighter can help drag the hose into the structure as needed. He or she can also prevent the entry door from closing on a hoseline. Propping a door open is an option, but only if the door’s closing would block a means of egress.

Gaining Access to the Property

Firefighters may need to force their way through a fence or gate in order to reach the door to be opened. Property owners often install security fences and gates to prevent unauthorized access. Preincident surveys can provide information on the type of security used and the location of lock boxes.

Fences can be made of:

- Wood

- Masonry

- Chain-link

- Plastic

- Barbed wire

- Wire fabric

- Ornamental metal

Some fences are topped with barbed wire or razor ribbon. Fences may also be used to contain livestock, pets, or guard dogs for security. Adequate size-up and using the most efficient tools and techniques are crucial when forcing entry through fences and gates.

Firefighters may sometimes encounter electrified fences. Take care when cutting these fences to prevent electrical shocks. If possible, de-energize the fence before cutting; if not, take insulation precautions to avoid electric shock or find other means of entry.

![]()

Fencing material that is stretched tight can recoil when it is cut, inflicting injuries to firefighters. Stand beside the fence post and cut the wire where it joins the post. When it is cut, it will recoil in the direction of the next post. Cut wire fences near posts to facilitate repair after the incident, provide adequate space for fire apparatus access, and reduce the danger of injury from the recoil of wires when they are cut. Alternatively, cut the wire bands holding the fence material to the posts and lay the material on the ground.

Various fences can be forced in several ways:

- Cut barbed wire fences with bolt cutters.

- Cut chain-link fences with a rotary saw; bolt cutters may be used as well but are slower.

![]()

In the case of masonry and ornamental metal fences, it may be easier and faster to go over the fence than through it. A-frame ladders can be used to bridge these fences. Security fences will have access points with locked or controlled gates.

Security gates are commonly used for:

- Residential housing complexes

- Industrial sites

- Construction sites

- Agricultural sites

Where continuous access is needed, such as industrial sites, gates may be staffed during operation hours. In other situations, the gates may be locked with chains and padlocks or other locking devices.

In residential complexes, electronic locks activated by a remote opener (similar to a garage door opener), barcode reader, or a keypad usually control gates. There may also be a lock box near the gate that contains an opener or keypad code (Figure 9.23).

If necessary, and if allowed by department SOPs, firefighters may force entry by prying the gate open or by using the apparatus bumper to force the gate. Fence gates are often secured with padlocks or chains and can be accessed using the techniques described previously. Gates used to secure patios, swimming pools, or backyards will usually have internal key-operated deadbolt locks. These gates are best accessed using through-the-lock and rim-lock techniques. Prying or cutting the gate should be the last method chosen because of the amount of damage that will be done to the gate and fence.

** NOTE: Some gates on commercial sites may be provided with special padlocks and/or electronic key switches that are operated with the same key used to access lock boxes. **

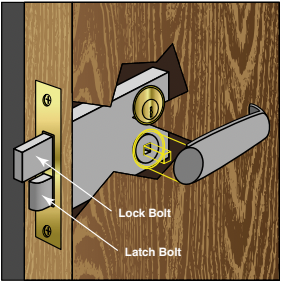

Door Locks/Latches

Locks and latches are part of the hardware normally found on all exterior doors and many interior doors. Door latches keep the door closed and consist of a handle on both sides of the door and a spring-loaded bar that extends into a receiver in the doorframe. It may or may not have a lock as part of the assembly.

Locks can be divided into four basic types:

- Mortise lock

- Cylindrical lock

- Rim lock

- High security locks

Mortise Latch and Lock

The mortise latch and lock assembly is mounted in a cavity in the door edge. Older mortise assemblies have only the latch to hold the door closed, while newer units consist of both a latch and a key-operated deadbolt (Figure 9.24). When the mechanism is in the locked position, the bolt protrudes from the lock into a receiver that is in the jamb. The latch may be operated with a doorknob or lever.

Mortise locks are used on exterior wood and metal doors and can be found on:

- Private residences

- Commercial buildings

- Industrial buildings

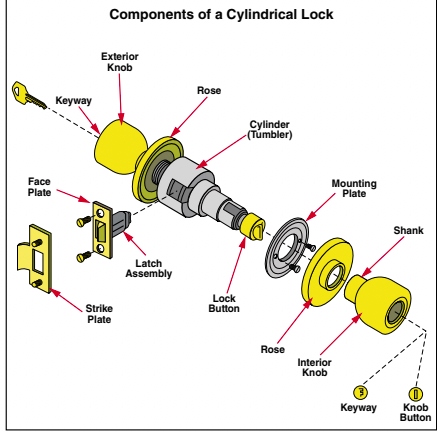

Cylindrical Lock

Cylindrical locks are the most common type of lockset found in residential applications. Their installation involves boring two holes at right angles to one another: one through the face of the door to accommodate the main locking mechanism and the other in the edge of the door to receive the latch or bolt mechanism. The two types of cylindrical locks are the key-in-knob lock and the tubular deadbolt lock.

The key-in-knob lock has a keyway in the outside doorknob; the inside knob may contain either a keyway or a button (Figure 9.25). The button may be a push button or a push-and-turn button. Key-in-knob locks are equipped with a latch mechanism that locks and unlocks using both the key and, if present, the knob button. In the unlocked position, a turn of either knob retracts the spring-loaded bevelled latch bolt, which is usually no longer than 3⁄4-inch (19 mm). Because of the relatively short length of the latch, key-in-knob locks are some of the easiest to pry open. If the door and frame are pried far enough apart, the latch clears the strike and allows the door to swing open.

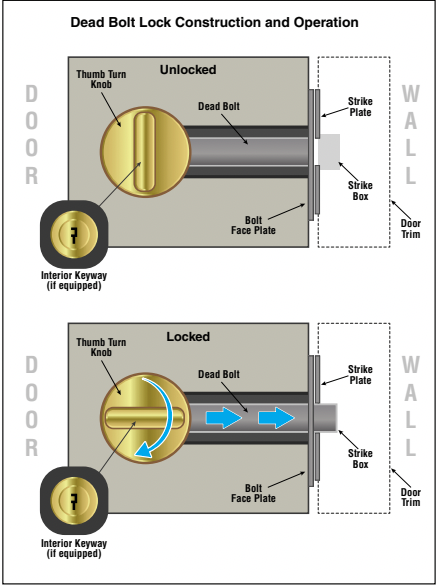

The tubular deadbolt lock is mounted above the doorknob and may have a single-cylinder or double-action cylinder. The single-cylinder deadbolt has a keyway on the outside of the door and a thumb-turn knob on the inside (Figure 9.26). The double-cylinder lock has a keyway on both sides of the door.

** NOTE: The easiest way to breach modern deadbolts in a wood residential door is to force the door itself. **

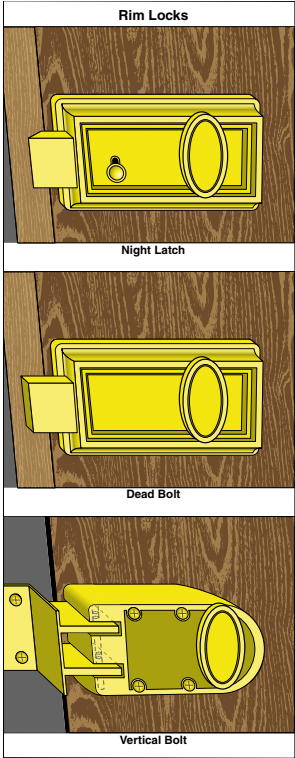

Rim Lock

A rim lock is mounted on the interior door surface and is used as a supplemental lock for doors that may or may not have other types of locks. Turning a thumb-turn knob on the inside of the door operates rim locks.

This lock is found in all types of occupancies, including:

- Houses

- Apartments

- Some commercial buildings

Although some rim locks have a keyway in a cylinder on the exterior of the door, not all do, making it difficult to recognize their presence.

A variety of rim locks are currently available including the following (Figure 9.27):

- Night latch: This rim lock has a spring-loaded bolt with a bevelled edge facing the doorframe. This feature allows the door to lock when it is closed.

- Deadbolt: This rim lock has a rectangular bolt that you must manually retract before the door can be closed and the bolt engaged with the receiver. If the bolt is extended, the door cannot be closed.

- Vertical deadbolt: This rim lock has a bolt that slides vertically into the receiver and does not cross the door opening and makes it impossible to open by spreading the door from the doorjamb.

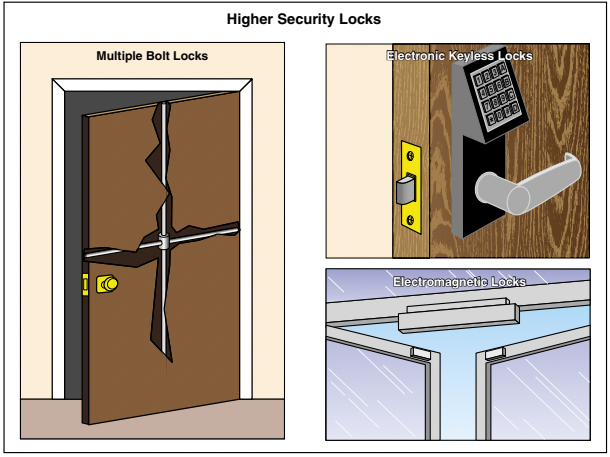

High-Security Locks

High-security locks include (Figure 9.28):

- Multiple bolt locks

The multiple bolt or multilock is a deadbolt lock that, when engaged, projects bolts 1 inch (25 mm) into two or more points on one edge of the door. Some versions extend hardened steel bolts into all four edges of the doorframe. The lock may have a thumb-turn knob or keyway on the inside of the door as well as a keyway on the exterior. A surface-mounted version may also be encountered.

Figure 9. 28 - Electronic keyless locks

Found on both exterior and interior doors. The locks are generally battery-powered. Some keypads may also have a keyway. They are used for areas that require continuous security and controlled access. Keyless or digital locks may have a:- Keypad

- Card reader

- Fingerprint-activated screen

- The locks are generally battery-powered. Some keypads may also have a keyway. They are used for areas that require continuous security and controlled access.

- Electromagnetic locks

The electromagnetic or magnetic lock consists of an electromagnet attached to the doorframe and an armature plate mounted on the door. An electric current passing through the electromagnet and the armature plate holds the door shut. Shutting off the power will release the door.

Locking Devices

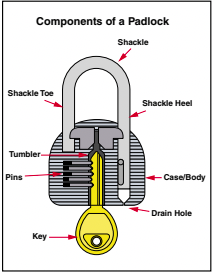

Locking devices may be supplemental to the door lock or used in place of it. The best example of locking devices are padlocks. Other devices, such as door chains or drop bars, impede entry but are not locks in the traditional sense.

Padlocks are portable or detachable locking devices (Figure 9.29). There are two basic types of padlocks: standard and heavy-duty. Standard padlocks have shackles of 1⁄4 inch (6 mm) or less in diameter and are not case-hardened steel. Heavy-duty padlocks have case-hardened steel shackles more than 1⁄4 inch (6 mm) in diameter. Many heavy-duty padlocks have what is called “toe and heel locking” where both ends of the shackle are locked when depressed into the lock mechanism. These shackles will not pivot if one side of the shackle is cut. To remove the lock, cut both sides of the shackle. Padlocks may be key or combination operated.

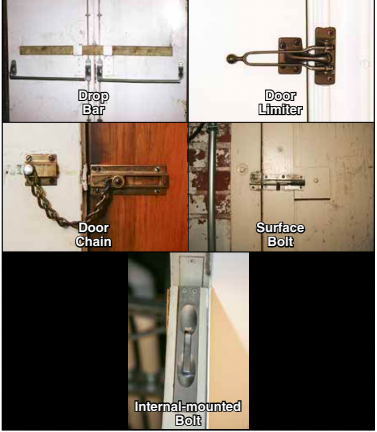

Other locking devices include the following (Figure 9.30):

- Drop bar: Brackets are bolted or welded to the door and a wood or metal bar rests in the brackets and extends across the doorframe.

-

Figure 9. 30 Door chain: The door chain is a supplemental locking device for residential doors. A chain permits the door to be opened enough for a person within a residence to see and speak to a visitor but still restrict access.

- Door limiter: Restricts the opening of the door and is similar to the supplemental security locks found in hotel rooms. The door limiter consists of a frame-mounted plate with a shaft and knob and a hinged U-shaped shackle that mounts on the door.

- Surface bolt: Manually operated supplemental locking devices that can be mounted on most doors and some windows.

- Internal-mounted bolt: Flush bolts are installed in the edge of one side of a set of double doors. This permits one side to remain locked while the other door is used for entry and exit. When desired, the bolts can be retracted and both doors opened.

Coordinating Forcible Entry and Door Control

Forcible entry creates a ventilation opening in a structure and changes the flow path of hot fire gases. Forcing entry also introduces a new source of oxygen to the fire in the structure. As a result, forcible entry must be coordinated with whatever interior activities require entry. Before forcing entry, personnel should be prepared to enter a structure to conduct search and rescue or interior fire attack. The longer the time between forcing an opening or breaking glass and the beginning of an interior fire attack or search and rescue, the more time the fire has to entrain new oxygen and grow.

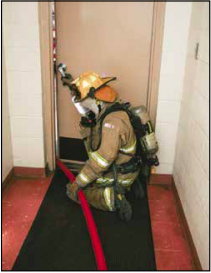

A door may not close properly once it is forced. You or another firefighter

should be assigned to monitor the door to control the flow path and to keep the door closed unless coordinated tactics require it to be open (Figure 9.31).

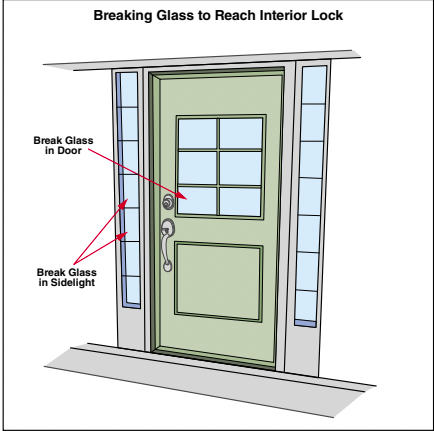

Breaking Door Glass

One of the fastest and least destructive techniques for forcing locked doors is to break the glass in the door or the sidelight next to it (Figure 9.32). Once the glass is broken, the firefighter can reach inside and unlock the door. In some situations, breaking the glass (or what appears to be glass) may be more difficult and costly. Tempered glass is very expensive, and PlexiglasTM and Lexan® may resist being broken with conventional hand tools.

Ordinary window glass will shatter into sharp fragments when broken. Firefighters should wear full protective equipment, especially hand and eye protection, to prevent injuries from shattered glass. If firefighters are break-ing the glass to gain access into a burning building, they should wear SCBA and have a charged hoseline in place, ready to attack the fire. The techniques used for breaking both door glass and window glass are similar.

Consider that glass doors or glass in doors are part of the barrier to ventilation. Breaking the glass will have the same effect on the flow path as opening the door; however, the glass cannot be “unbroken.” Once the glass is broken, that doorway is a ventilated opening to the fire for the remainder of the operation.

Forcing Swinging Doors

The most common type of door is one that swings at least 90 degrees to open and close. Most swinging doors have hinges mounted on one side that permit them to swing in one or both directions; others swing on pivot pins at the top and bottom of the door. Swinging doors can be either inward-or outward-swinging or both. Double-acting swinging doors are capable of swinging 180 degrees. An easy way to recognize which way a door swings is to look for the hinges. If you can see the hinges of the door, it swings toward you. If you cannot see the hinges, the door swings away from you. Forcing entry through swinging doors involves basic skills and requires practice to master.

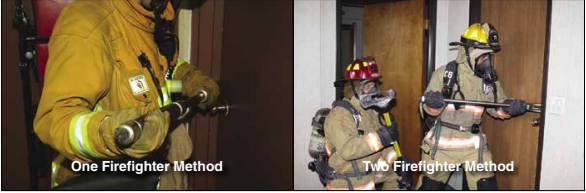

Inward-Swinging Doors

Forcible entry of single inward-swinging doors requires one or two skilled firefighters, depending upon the tool or tools used. For example, a single firefighter using a rambar can open most standard swinging doors; however, if a Halligan tool and flat-head axe are used, two firefighters are required (Figure 9.33).

Skill Sheet 9-2 describes two techniques for forcing entry through a single, inward-swinging door.

If the swinging door is metal or metal-clad in a metal frame set in a concrete or masonry wall, you may need

other forcible entry techniques. In some cases, you can use a hydraulic door opener (often called a rabbit tool) to force the door open. In other cases, doors resist being pried open, so it is necessary to cut around the lock in either of two ways. First, you can use a rotary saw with a metal cutting blade to make two intersecting cuts that isolate the locking mechanism and allow the door to swing. A second method using three intersecting cuts can also produce the same result.

Outward-Swinging Doors

Because the hinges on outward-swinging doors are mounted on the outside, it is often possible to use a nail set and hammer to drive the pins out of the hinges and simply remove the door. If the hinge bottoms are solid and the pins cannot be driven out, it may be possible to break off the hinges with a rambar or Halligan. It may be possible to cut off the hinges with a rotary saw or a cutting torch (Figure 9.34). You can also insert the blade of a rambar or Halligan into the space between the door and the doorjamb and pry that space open wide enough to allow the lock bolt to slip from its keeper.

Skill Sheet 9-3 illustrates two methods of forcing entry through an outward-swinging door.

Double-Swinging Doors

Double-swinging doors can present a problem depending on how they are secured. If only a mortise lock secures the doors, you can insert the blade of a rambar or wedge of a Halligan between the doors to pry them far enough apart for the bolt to slip past the receiver. You can insert a metal-cutting blade of a rotary saw into the space between the doors to cut the deadbolt (Figure 9.35). Some double doors have a security moulding or weather strip over the space between the doors. Remove this moulding or cut away a section to allow the blade of the forcible entry tool to be inserted.

Doors with Drop Bars

If a single or double-swinging door is locked with a drop bar, try one of the following methods to force entry:

- Use a rambar or Halligan tool to spread the space between the double doors. Insert a handsaw blade or other narrow tool through the opening and lift the bar up and out of the stirrups.

- Use a rotary saw to cut the exposed bolt heads that are holding the stirrups on the outside of the door. This will allow the drop bar to fall away and the door to be opened.

- Insert a rotary saw blade through the space between the double doors and cut the security bar.

Tempered Plate Glass Doors

In commercial, light industrial, and institutional occupancies, firefighters may be faced with metal-frame doors with tempered plate glass panels. These doors are heavy and very expensive. Tempered glass mounted in a metal doorframe can be very difficult to break. Unlike regular plate glass, tempered glass resists heat; when broken, it shatters into thousands of tiny cubelike pieces.

Only as a last resort should you break tempered plate glass doors. If a tempered plate glass door must be broken, use the following guidelines:

- Use the pick end of a pick-head axe and strike the glass at the bottom corner.

- Wear complete PPE including a helmet-mounted face shield or goggles to protect against eye injury.

- Place a salvage cover against the glass and strike through the cover to shatter the glass (Figure 9.36).

- Scrape any remaining glass from the frame.

** NOTE: If you want to avoid breaking the glass, you can also use the through-the-lock method to open tempered plate glass doors. **

Forcing Sliding Doors

Sliding doors consist of two glass panels mounted in wood, aluminum, or vinyl-clad material. One panel is stationary while the other slides in a track on small guide wheels or rollers. Sliding doors, sometimes called patio doors, are often found in single-family residential structures and apartment buildings. Locking devices include latches on the inside of the door and security bars placed in the track. Forcible entry techniques include breaking the glass with an axe or lifting the sliding panel up and out of its track. Attempting to spread the door from the frame will result in the door shattering uncontrollably.

A second type of sliding door is the interior pocket door. It may consist of one- or two-door panels that slide into the adjacent wall. You can force pocket doors using the same techniques used to force a swinging door.

Forcing Security Doors and Gates

Firefighters will encounter security doors and gates in a number of forms including:

- Rollup doors, both manual and power operated

- Doors with open steel bars

- Doors that consist of multiple slats that can be closed to form a solid panel

Security doors or gates will delay entry and will require planning to determine the most efficient form of entry. Some doors may have padlocks on the outside while others may have locks on the inside. If the lock is inside, there is usually a second means of entry into the structure. Forcible entry techniques include cutting off the padlock, using a rotary saw to make an opening near the lock, or cutting out a section of the door (Figure 9.37). You should know the specific types of security doors and gates in your response area and practice the correct procedure for each.

Through-the-Lock Forcible Entry

The through-the-lock method is preferred for many:

- Commercial doors

- Padlocks

- Residential security locks

- High-security doors

Through-the-lock forcible entry requires a good size-up of both the door and the lock mechanism. Firefighters can use the through-the-lock entry method if the door does not open with conventional forcible entry methods. his technique is very effective and does minimal damage to the door when performed correctly.

Skill Sheet 9-4 describes three methods of forcing entry through a door lock.

On some door locks, the lock cylinder can be unscrewed from the door. Storefront doors often have locks that can be unscrewed because it makes it easier for locksmiths to rekey the locks when occupancy changes.

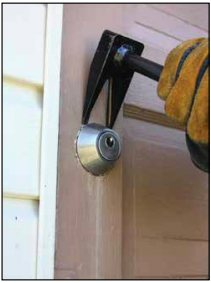

Removing the lock cylinder is only half the job. A key tool must then be inserted to open the lock in the same fashion as inserting a key (Figure 9.38). The key tool is usually flat steel with a bend on the cam end and a flat screwdriver-shaped blade on the other.

Along with standard forcible entry striking and prying tools, special tools may also be needed for this forcible entry technique.

Some examples of these special tools include:

- K-tool

- A-tool

- J-tool

- Shove knife

K-Tool

A K-tool gripping a lock cylinder (left). Two firefighters setting a K-tool onto a door’s lock cylinder.

The K-tool is a V-blade tool useful in pulling lock cylinders. The K-tool is forced behind the cylinder’s ring and face until the wedging blades bite into the cylinder. A metal loop on the front of the K-tool provides a slot in which to insert one end of a prying tool. A firefighter then strikes the top of the prying tool with a flat-head axe or other striking tool to set the K-tool (Figure 9.39). Once set, the firefighter uses the prying tool to pull the K-tool and the lock cylinder from the door.

When a lock cylinder is located close to the threshold or jamb, the narrow blade side of the K-tool will usually still fit behind the ring. Some sliding glass doors have limited clearance, but only a 1⁄2-inch (13 mm) clearance is needed. Once the cylinder is removed, insert a key tool into the hole to move the locking bolt to the open position.

A-Tool

The A-tool is a prying tool with a sharp notch with cutting edges machined into it. The notch resembles the letter A. The A-tool can often accomplish the same job as the K-tool, but it can cause slightly more damage to the door. The A-tool was developed to force entry on locks manufactured with collars or protective cone-shaped covers over them to prevent the lock cylinder from being unscrewed. The A-tool is designed to cut behind the protective collar of a lock

cylinder and maintain a hold so that the lock cylinder can be pried out. The curved head and long handle are then used to provide the leverage for pulling the cylinder (Figure 9.40). The chisel head on the other end of the tool is used when necessary to gouge out the wood around the cylinder for a better bite of the working head. Use the A-tool when pulling protected deadbolt lock cylinders and collared or tubular locks.

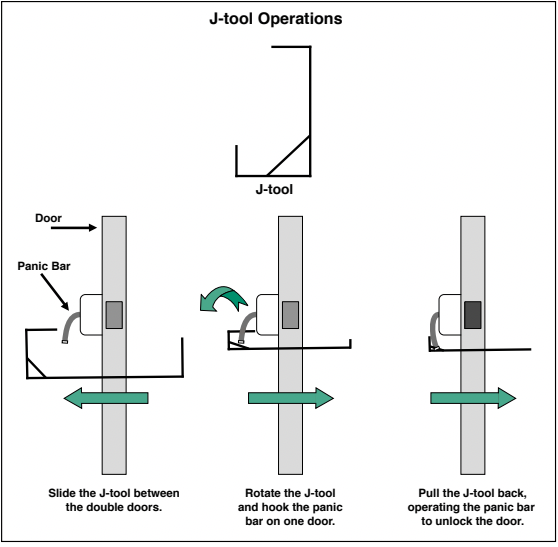

J-Tool

The J-tool is a device made of rigid, heavy gauge wire designed to fit through the space between double-swinging doors equipped with panic hardware (Figure 9.41). The J-tool is inserted between the doors far enough to allow the tool to be rotated 90 degrees in either direction. A firefighter can then pull the tool until it makes contact with the panic hardware. The firefighter then makes another sharp pull, and the tool should operate the panic hardware and allow the door to open.

Shove Knife

This flat steel tool, resembling a wide-bladed putty knife with a notch cut in one edge of the blade, can provide firefighters rapid access to outward swinging latch-type doors. When used properly, the blade of the tool depresses the latch, which allows the door to open (Figure 9.42).

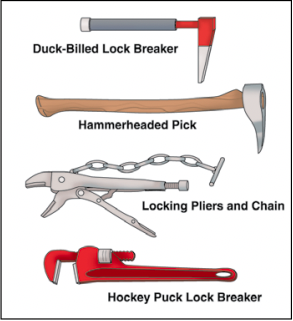

Forcing Padlocks

Firefighters must be capable of forcing either the padlock itself or the device to which it is fastened. Firefighters can use conventional forcible entry tools to break a padlock or detach the hasp to gain access (Figure 9.43).

The following tools are available to make forcible entry through padlocks easier (Figure 9.44):

- Duck-billed lock breaker: Wedge-shaped tool that will widen and break the shackles of padlocks, much like using the hook of a Halligan-type tool. Insert this tool into the lock shackle and strike the tool with a maul or flat-head axe until the padlock shackles break.

- Hammerhead pick: Has a pick on one end of the tool head and a hammerhead or striking surface on the other. Insert the pick into the padlock shackle and strike the tool with a maul or flat-head axe until the padlock shackles break.

- Locking pliers and chain: Lock the locking pliers firmly onto the body of the padlock. To keep the padlock stable, hold onto the chain. To cut both shackles, another firefighter uses a power saw or torch.

- Hockey puck lock breaker (pipe wrench): Adjust the pipe wrench to grip the hockey puck lock firmly. Apply downward pressure to the end of the wrench’s handle to twist the lock and break its interior mechanism.

Skill Sheet 9-5 describes several methods of forcing entry through a padlock.

If these techniques fail to break the padlock, break the hasp or detach it from the doorframe. If the shackle of the padlock exceeds 1⁄4 inch (6 mm) and the lock, including the body, is case-hardened, the firefighter faces a more difficult forcible entry task.

Using a rotary saw with a metal-cutting blade or a cutting torch may be the quickest method for removing some padlocks. High-security padlocks are designed with heel and toe shackles. These shackles will not pivot if only one side of the shackle is cut. Cutting padlocks with a power saw or torch can be somewhat dangerous.

Use the following techniques for removing this type of padlock:

- Stabilize the lock with a set of locking pliers.

- Attach a chain to the lock and pull it straight away from the hasp.

- Request a second firefighter to cut both sides of the padlock shackle with the saw or torch.

Forcing Overhead Doors

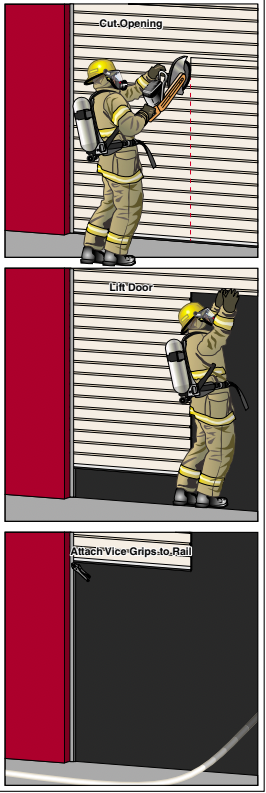

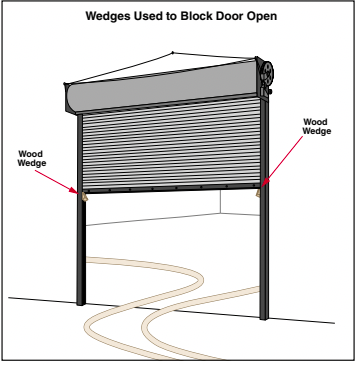

When forcing overhead doors, use a rotary saw to cut a square or rectangular opening about 6 feet (2 m) high and nearly the full width of the door. Once you have access to the interior, use the lift mechanism to open the door fully. Use cribbing or shoring blocks to prevent overhead doors from closing unintentionally. Attach a pair of vice grips (locking pliers) to the overhead door rail above head height to keep the door from closing (Figure 9.45).

Forcing Fire Doors

Fire doors are movable assemblies designed to cover doorway openings in rated separation walls to prevent the spread of fire from one part of a building to another. Types of standard fire doors include sliding, swinging, and overhead rolling varieties. Fire doors are normally found on the inside of structures, separating one area from another, enclosing a hazardous process or storage area, or protecting a means of egress (exit path such as a protected stairway).

Exterior fire doors are usually found where a structure must be protected from an adjacent exposure. Because the door is on the outside of the structure, it will probably be locked. Forcible entry should be similar to any other overhead or sliding door.

Interior fire doors will be activated manually or automatically when the fire is detected. Because these doors only operate when there is a fire, they will not lock in place when closed. When passing through an opening that a fire door protects, block the door open to prevent it from closing and blocking a means of egress or cutting off the hoseline water supplies (Figure 9.46).

Fire doors are a part of the protection system in the structure; however, there may be times when you may need to force fire doors. They are positioned to create separations with higher-than-normal fire-resistance ratings. Leaving fire doors in place is preferable — much like not interfering with sprinkler systems. Use caution when propping these doors open or forcing them because it also changes the flow path.

Lesson 4

Outcomes:

- Describe methods for forcing entry through windows

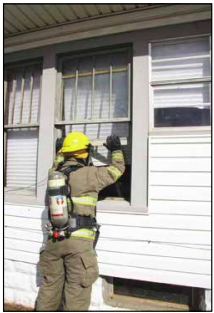

Forcing Entry Through Windows

Windows are sometimes easier to force than doors even though they are not the best entry point into a burning building (Figure 9.47). Entry can be made through a window to open a locked door from the inside. As with doors, the size-up of windows is critical to a successful forced entry. Forcing open the wrong window may also disrupt ventilation efforts, intensify fire growth, and draw fire to uninvolved sections of the building.

Breaking Window Glass

The most common technique used is breaking the glass, but it creates the following hazards and obstacles:

- Slows entry into the structure while firefighters clear the glass shards from the frame.

- Creates flying glass shards that may travel great distances from windows on upper floors.

- Covers floors in glass shards which can make footing treacherous for firefighters advancing charged hoselines.

- Could shower glass on victims inside the structure causing additional injury.

- Changes the flow path.

- Cannot be undone once the glass is broken.

** NOTE: When using a pike pole to break a window, position yourself upwind and higher than the window so that falling glass will not slide down the handle toward you. **

Wire glass is more difficult to break and remove than ordinary window glass because the wire prevents the glass from shattering and falling out of the frame (Figure 9.48). Use a sharp tool, such as the pick of an axe, to chop wire glass out of its frame.

Safety film is a product often applied to windows in high-rises, schools, or larger structures. The film acts as an adhesive that prevents particles or shards of glass from falling when the glass breaks. Safety film can impede breaking windows during operations. Where the safety film is present, cutting tools rather than striking tools may be required to break the windows.

Because windows containing two and three layers of glass are expensive, firefighters must decide if the benefits of breaking the window outweigh the expense of replacing the windows. Multipaned windows are also time-consuming to remove because the glass is held in place by a rubber cement which makes shard removal difficult.

Skill Sheet 9-6 describes the general techniques for forcing entry through a glass pane window.

** NOTE: Chapter 3, Building Construction, provides information on the various window types, functions, and materials that firefighters may encounter. **

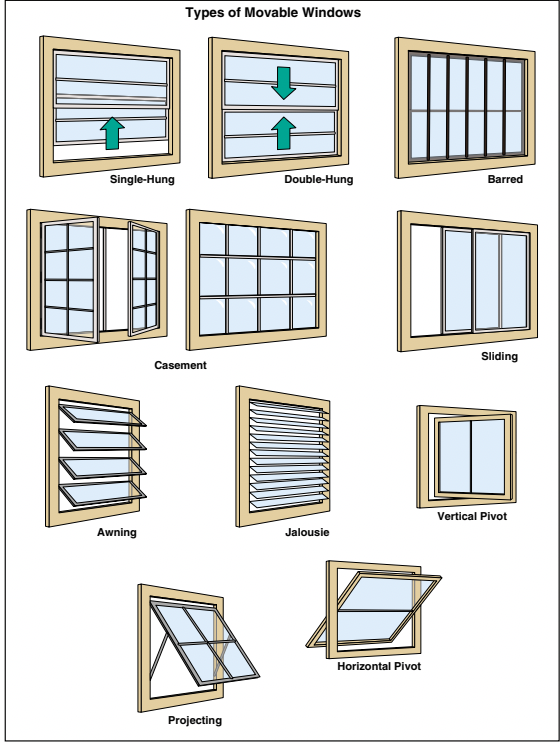

Forcing Windows

Forcible entry through windows can be made using a variety of approaches depending upon the window’s construction (Figure 9.49).

Forcible entry approaches to various window constructions include:

- Fixed Windows: Force fixed windows or block window walls only as a last resort. These walls are 2 to 4 inches (50 to 100 mm) thick and may be individual blocks held together with mortar or vinyl strips or manufactured panels of blocks up to 47 inches (1 190 mm) square. To break these windows, you may need a sledgehammer or battering ram.

- Double-Hung Windows: Forcible entry techniques for double-hung windows depend on how the window is locked and the material of which the sash frames are made. Metal-frame windows are more difficult to pry. The lock mechanism will not pull out of the sash and may jam, creating additional problems. Use the same technique given for a wood-frame window, but if the lock does not yield with a minimal amount of pressure, it may be quicker to break the glass and open the lock manually. In addition to describing glass-pane entry techniques, Skill Sheet 9-6 illustrates the method of forcing entry through a double-hung window.

- Single-Hung Windows: Single-hung windows are identical to double-hung windows with the exception that only the bottom panel moves. Locks and locking devices are the same as those found on the double-hung windows. Forcible entry procedures are also the same as those used on the double-hung window.

- Casement Windows: To force open a single-casement window, break the lowest pane of glass and clear shards from the frame. Cut open the window screen behind in the same area. Reach in and unlock the locking mechanism, operate the crank to open the window frame, and then remove the screen completely. If the window has one full pane of glass, break it, clear the shards from the frame, and remove the screen. It will be unnecessary to crank it open once the glass is removed.

- Horizontal Sliding Windows: The technique for forcing entry through a horizontal sliding window is the same as that used with the sliding door.

- Awning Windows: Forcible entry through awning windows requires that you either break the glass or pry the window up from the frame.

- Jalousie Windows: You must remove several panes to enter through these windows. Because most awning and jalousie windows are relatively small, they offer very restricted access even when all of the glass is removed. As an alternative, if you must enter through a jalousie window, it may be faster and more efficient to cut through the wall around the entire window assembly and remove it.

- Projecting Windows: Forcing entry through projecting windows may be limited to breaking the glass or cutting the window panel out of the frame.

- Pivoting Windows: Forcing entry through these windows follows the same procedure as the projecting window.

- Barred Windows: If there are sufficient resources available, remove all security bars from the building to allow for emergency egress when crews are operating inside the building. Security grilles or screens may be permanently fixed, hinged at the top or side, or fitted into brackets and locked securely. Security grilles or screens that are hinged can be opened easily if the lock is accessible and can be cut from the frame. If not, you can cut the screen fabric with a rotary saw. Once you remove the screen, the window must be forced as previously described.

Lesson 5

Outcomes:

- Describe methods for breaching walls.

Breaching Walls

In situations where doors and windows are inaccessible or heavily secured, it may be faster and more efficient to gain access through the structure’s wall. Creating a hole in a wall is known as breaching. Breaching requires a thorough knowledge of building construction, accurate size-up of the situation, and determination that breaching a particular wall is safe and will accomplish the purpose. Exterior walls will be more difficult to breach than interior walls as described in the following sections.

Exterior Walls

Firefighters must consider possible collapse and safety hazards before breaching exterior walls. Breaching load-bearing exterior walls in fire-weakened structures could cause a partial or total collapse.

Exterior and interior walls also conceal:

- Electrical wires

- Gas pipes

- Water pipes

- Components of the building utilities

Firefighters outside the structure will be unable to determine if these concealed components exist in an exterior wall.

Exterior walls may be:

- Wood frame

- Poured concrete

- Brick or concrete block

- Metal construction

Wood Frame Walls

Exterior wood frame walls consist of vertical 2 x 4 or 2 x 6 inch (50 by 100 mm or 50 by 150 mm) studs covered on the inside with gypsum sheets or lath-and-plaster while the outside is covered with wood, composite boards, or other materials.

Studs are placed 16, 20, and sometimes 24 inches(400, 500, and 600 mm) apart. The spaces may be void or contain some form of insulation material. Wood siding may be hardwood boards, shake shingles, or panels made of plywood or composite materials.

Firefighters can cut wood frame walls with an axe or shatter them with sledgehammers before prying the wall open using a crowbar or Halligan (Figure 9.50). When using hand tools, it is safest to strike and make cuts toward the centre of the opening you want to create first. Attempting to cut at the corners of the intended opening may be more difficult and unsafe for the firefighter breaching the wall. After the exterior wall is opened, the interior wall is then penetrated.

Skill Sheet 9-7 illustrates suggested methods for forcing entry through a wood-framed wall with hand tools, a rotary saw, or a chain saw.

Brick or Concrete Block Walls

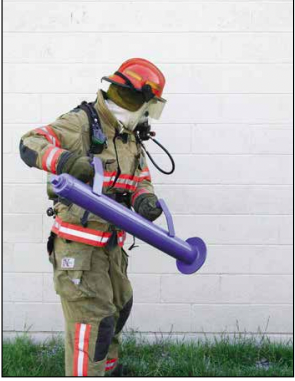

The traditional approach to breaching a masonry wall has been to use a battering ram. Breaching with a battering ram can be slow and labour-intensive. Therefore, it is best suited for opening a small hole in a wall through which water can be applied to a fire on the other side of the wall (Figure 9.51). While it is possible to use a battering ram to create an opening large enough for firefighters to pass through, it is impractical.

Power tools such as rotary saws with masonry

blades or pneumatic or electric jackhammers are best for breaching brick and concrete block walls. They are faster and usually require only one person to operate. If these tools are not available and a wall needs to be breached to allow water to be applied to a fire on the other side of the wall, you can drive a penetrating (drive-in) nozzle through the wall or make an opening large enough to accept a conventional nozzle (Figure 9.52). When breaching with hand tools, striking the middle of the wall is more efficient than starting near the top or bottom.

Skill Sheet 9-8 describes the method for breaching a masonry wall using hand tools.

Concrete Walls

Breaching poured concrete walls is even slower and more labour-intensive than breaching brick or concrete block walls. In addition to the density of the material, the wall is often reinforced with steel rebar. Therefore, only breach concrete walls when necessary and no other alternative is available. Several power tools can be used to breach concrete walls. One of the fastest and most efficient tools to breach concrete walls is a chainsaw equipped with a diamond-tipped chain. If a chainsaw is not available, a pneumatic jackhammer can be used.

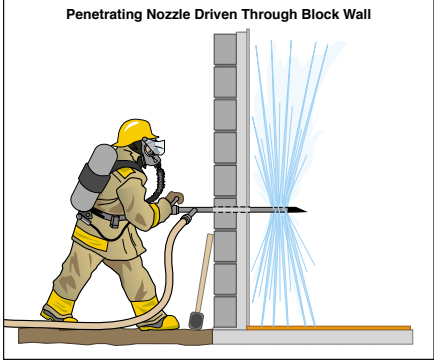

Metal Walls

Metal walls are common in commercial and industrial occupancies in both rural and urban settings. These walls are usually constructed of overlapping light-gauge sheet metal panels fastened to metal or wooden studs. Nails, rivets, bolts, screws, or other fasteners may be used to attach the panels. Conventional forcible entry tools, such as an axe, rotary saw, or air chisel, cut these thin metal panels with relative ease.

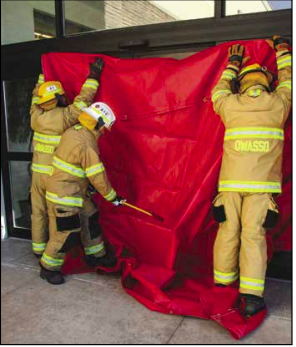

Ensure that building utilities are not located in the area selected for cutting. A charged hoseline or an appropriate fire extinguisher should be available when cutting metal with a rotary saw because of the sparks produced. Cut a square or rectangular opening that is large enough for firefighters to pass through easily. The opening should be at least 6 feet (2 m) tall and as wide as needed (Figure 9.53). If the wall must be breached to allow water to be applied to a fire on the other side of the wall, a penetrating nozzle can be driven through the metal siding.

Skill Sheet 9-9 describes the method for breaching a metal wall with a rotary saw.

Interior Walls Depending on the type of structure and its design, interior walls may be load-bearing or non-load-bearing. Construction materials may be:

- Masonry

- Glass block

- Poured concrete

- Lath-and-plaster

- Sheetrock®

The walls may contain electrical wires, water or gas pipes, or heating and cooling ducts. Your supervisor must determine what effect breaching the wall will have on the structural integrity before making the opening. The methods for breaching masonry, concrete, and glass block walls were described previously.

Plaster or Gypsum Partition Walls

Both load-bearing and non-load-bearing interior walls are designed to limit fire spread. Covering the wall with a variety of materials, including gypsum wallboard or lath-and-plaster over wooden or metal studs and framing, provides fire resistance. Both lath-and-plaster and gypsum wallboard are often relatively easy to penetrate with forcible entry striking hand tools or rotary and chain saws (Figure 9.54).

Reinforced Gypsum Walls

In some newer buildings, the interior walls in public access areas such as hallways, lobbies, and restrooms are covered with gypsum wallboard that is reinforced with Lexan®. Like other wallboard, reinforced wallboard is attached to the wall frame using drywall nails or screws. Reinforced wallboard looks identical to other wallboard because the Lexan® reinforcement is installed on the back of the wallboard. This wallboard is designed to resist breaching using conventional forcible entry hand tools. If firefighters are to breach this material in a timely fashion, they must know that they are not dealing with ordinary wallboard and must bring power saws with them when they enter the building. The only way they will know that the wallboard is reinforced is if the preincident planning survey identifies the wallboard material.

Chapter Review