61 Two and Four Stroke Engines

Learning Objectives

Outcomes: Explain the difference and advantages of two and four stroke engines

Key Questions: How do small engines operate and what is the difference between two and four stroke engines?

Learning tasks: Read course material, answer practice questions, complete online quiz

Topics: Operation theory of two and four stroke engines, advantages and limitations of two and four stroke engines

Assessment: online quiz

Estimates time: 1.5 hours

Four Stroke Engines

A four stroke engine is a type of internal combustion engine. It operates through four distinct stages: intake, compression, combustion, and exhaust. These stages collectively form one complete cycle of the engine.

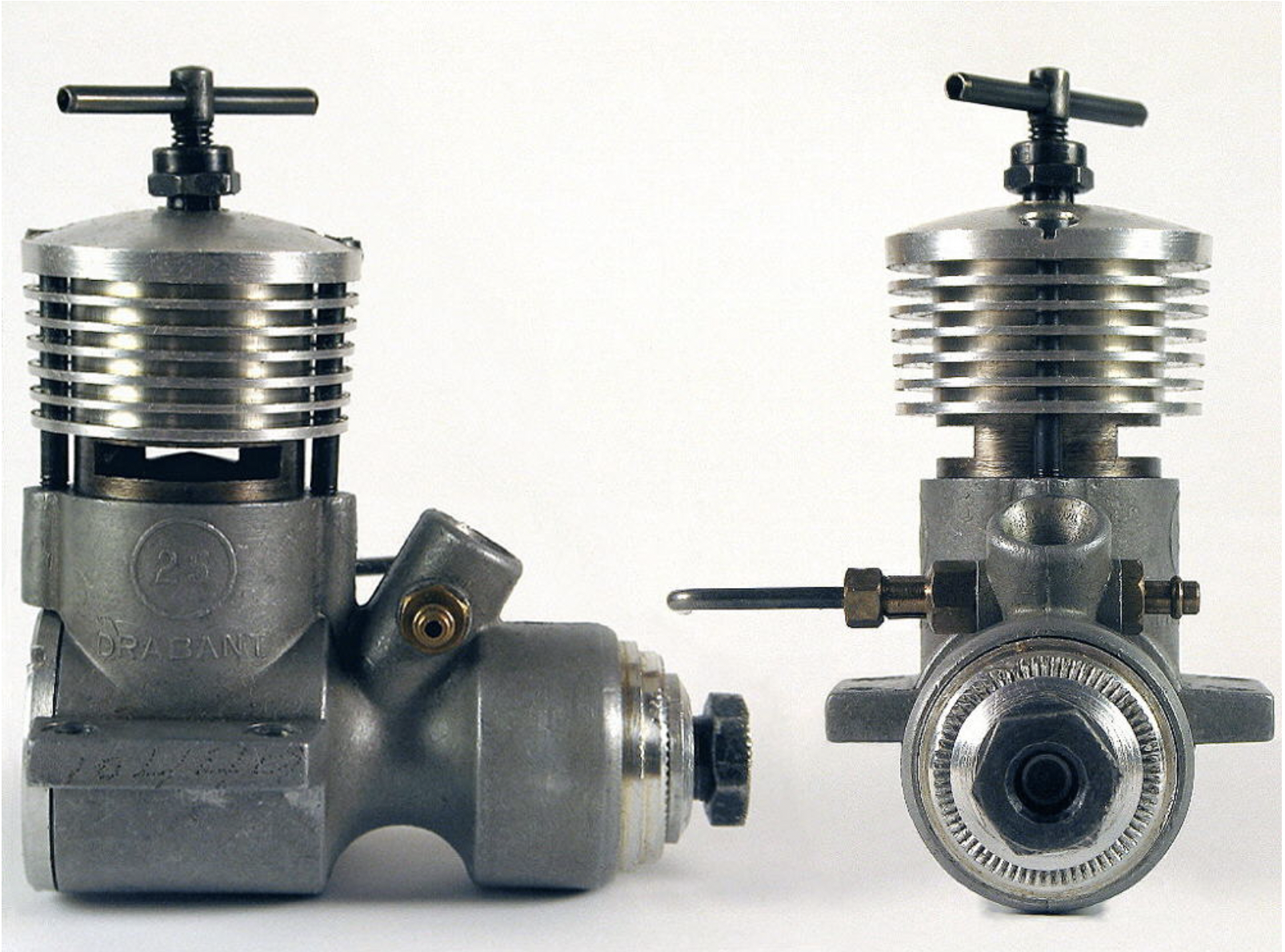

Four stroke engines are sometimes also referred to as four-cycle engines. They are similar in design to the standard automobile engines but differ in a few key ways. Four stroke engines are considerably smaller, they are cooled by air and not water, and generally only have one cylinder.

The power within the engine is produced by the explosive combustion of gasoline vapors inside a cylinder. A carburetor mixes gasoline and air to supply these vapors and a spark plug sets off the combustion. High pressures generated from this combustion force a piston down the cylinder bore, then the piston transfers its power to the crankshaft by means of a connecting rod. The interaction of the connecting rod crankshaft changes the up and down motion of the piston into rotary motion- like how pedaling up and down on a bicycle causes the rotation of the wheels. In the four stroke engine, there is one power stroke for every four up or down strokes of the piston.

Four stroke engines also use poppet valves, which are held closed by springs until the camshaft pushes them open. When closed, the valves must form a tight seal to maintain compression in the engine.

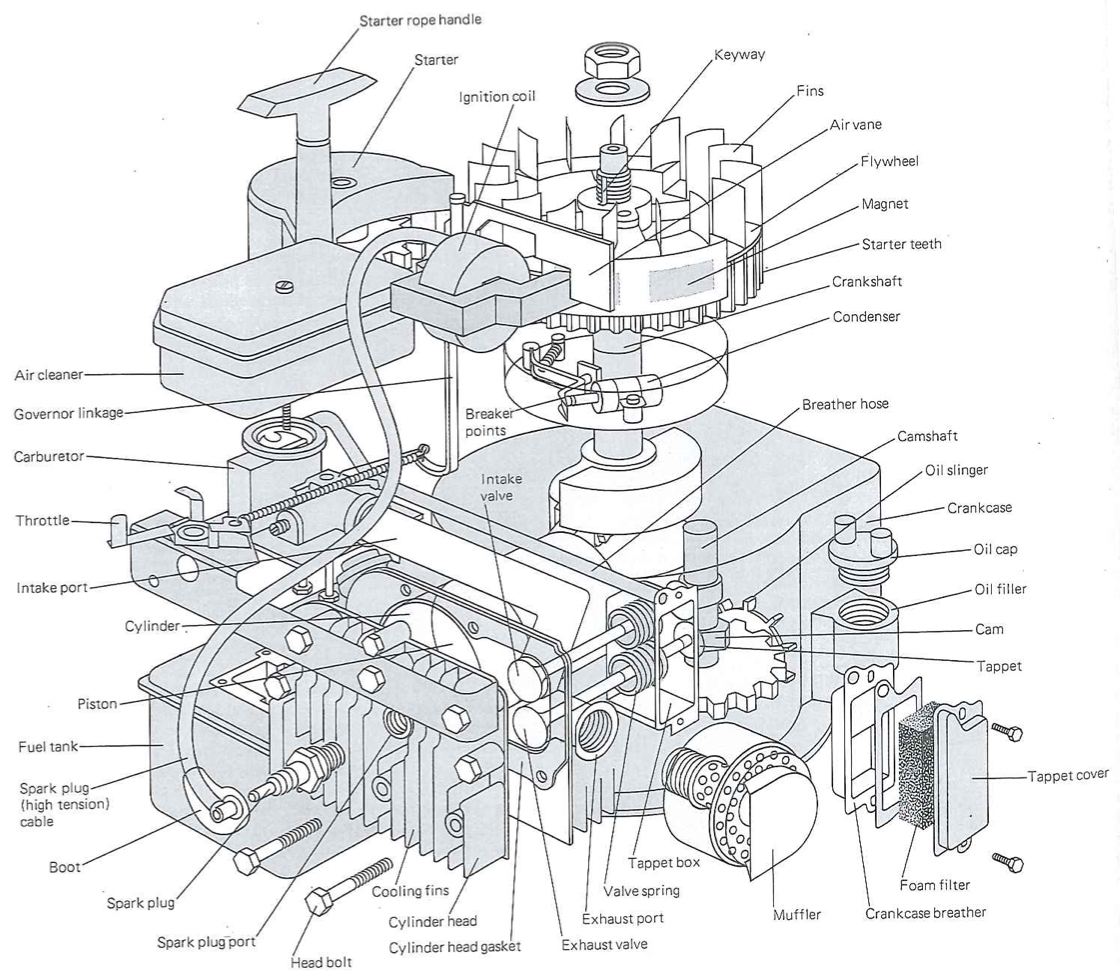

Components of a four-stroke engine include:

1. Cylinder: This is the central chamber where combustion takes place.

2. Piston: A cylindrical component that moves up and down inside the cylinder. It is connected to the crankshaft via a connecting rod.

3. Crankshaft: Converts the up and down motion of the piston into rotational motion. This rotation is ultimately transferred to the wheels of the vehicle.

4. Camshaft: Responsible for operating the intake and exhaust valves at precise timings during the engine cycle.

5. Valves: Intake and exhaust valves control the flow of air-fuel mixture into the cylinder and the exhaust gasses out of the cylinder, respectively.

6. Spark plug: Provides the spark necessary to ignite the air-fuel mixture in the combustion chamber.

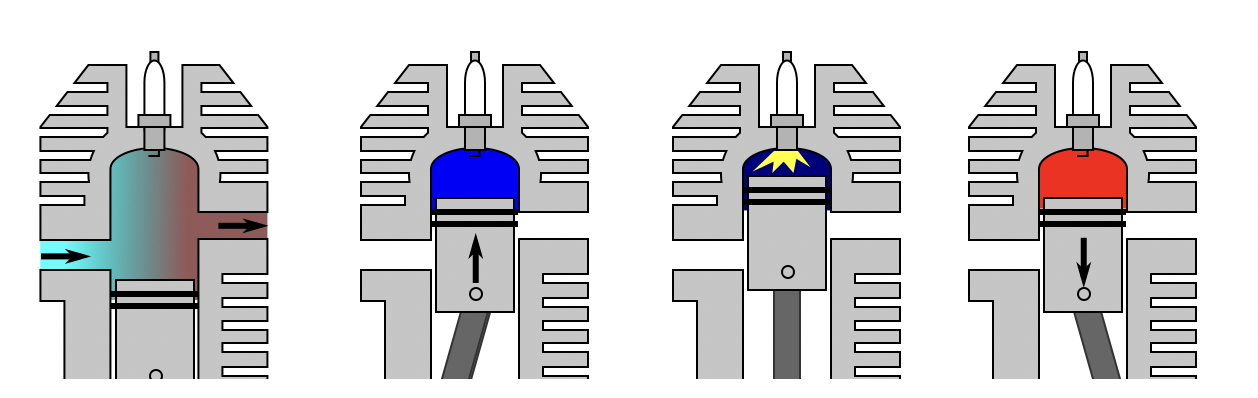

How Four-Stroke Engines Work

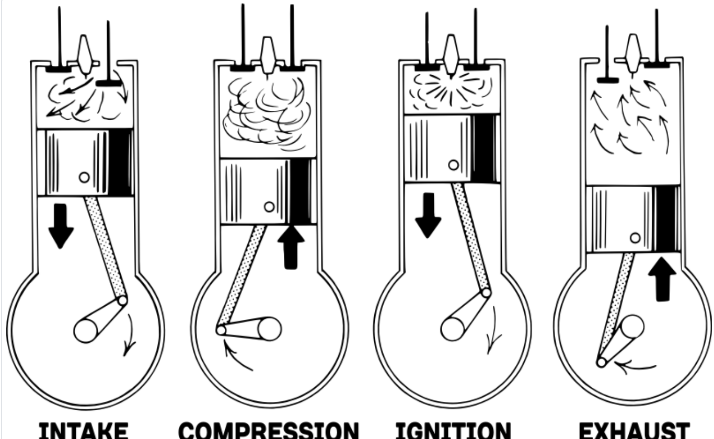

- Intake Stroke

egg-shaped cam on rotating camshaft forces the intake valve open. The piston moving down the cylinder draws in fuel-air mixture from the carburetor. - Compression Stroke

camshaft rotation allows the spring to close the valve. The piston moves back up the cylinder and compresses the fuel and air mixture near the top. - Power Stroke

The spark plug ignites the explosive mixture, and the expanding gasses force the piston rapidly down the cylinder, turning the crankshaft, flywheel, and camshaft. - Exhaust Stroke

Momentum carries the piston back up the cylinder, forcing the burned gasses out through the exhaust valve, which has been opened by the cam. - This process enables the engine to convert chemical energy stored in the fuel into mechanical energy, which is used to propel the vehicle.

Two Stroke Engines

A two-stroke engine is a type of internal combustion engine that completes a power cycle in just two strokes of the piston (one upstroke and one downstroke) during each combustion cycle. Two stroke engines are also known as two-cycle engines. This is because there is one power stroke for every second stroke of the piston. This occurs on each downward stroke.

Two Stroke Engine Animation (youtube.com)

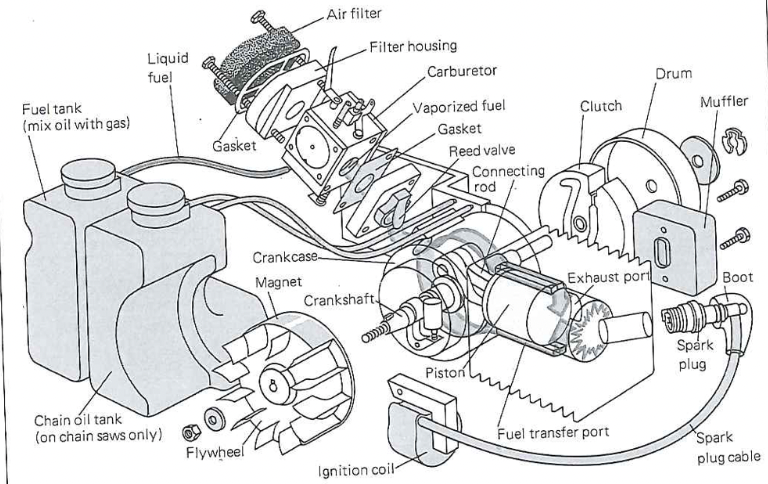

Because there is no exhaust stroke, the exhaust gasses must be released from the cylinder when the piston completes its power stroke. This is accomplished when the piston uncovers ports (or holes) in the walls of the cylinder during its downward movement.

The ports of a two-cycle engine serve the same purposes as the valves in a four-cycle engine. Some designs use a reed valve- a flexible strip of metal or plastic that serves as a one-way gate between the carburetor and the airtight crankcase. The reed valve controls the flow of the fuel-air mixture into a two-stroke engine.

The underside of the piston acts as a pump on the two-cycle engine, drawing the fuel-air mixture into the crankcase, and then forcing it up into the cylinder. The spark plug is fired by a magnetic ignition. Magnets in the flywheel generate an electrical current in a coil of a wire every time they pass it. When the breaker points are opened, this current jumps as high as 20, 000 volts and is transferred to the spark plug.

Components of a two-stroke engine include:

1. Cylinder: Similar to a four-stroke engine, the cylinder is where the combustion process occurs.

2. Piston: The piston moves up and down inside the cylinder, compressing the air-fuel mixture and transferring the generated power to the crankshaft.

3. Crankshaft: Converts the reciprocating motion of the piston into rotational motion.

4. Intake port: This allows the air-fuel mixture to enter the cylinder.

5. Exhaust port: Allows the burned gasses to exit the cylinder.

6. Spark plug: Ignites the air-fuel mixture to initiate combustion.

7. Transfer ports: Connect the crankcase to the cylinder and allow the fresh air-fuel mixture to enter the combustion chamber while simultaneously expelling the exhaust gasses.

How Two-Stroke Engines Work

On an upward stroke, the fuel mixture already in the cylinder is compressed. A vacuum is formed in the airtight crankcase by the rising piston. This draws more mixture from the carburetor and past the reed valve.

At the top of the stroke, pressure stabilizes in the crankcase and the reed valve springs shut. The spark plug fires and starts the power (downward) stroke.

On the downward stroke, power is transmitted to the crankshaft and the fuel-air mixture in the crankshaft is compressed by the descending piston.

Near the bottom of the stroke, the piston uncovers the ports and the pressurized fuel-air mixture rushes into the cylinder, forcing the burned gasses out of the exhaust port.

The Differences Between Four-Stroke and Two-Stroke Engines

The two stroke engine is lighter and more powerful than a four stroke engine of the same size because it has fewer parts, and gives twice as many power strokes per engine revolution.

But because it uses more fuel than a four-cycle engine, the two cycle engine is generally used only on machines that need an especially small or lightweight power plant, such as chainsaws. To determine if an engine is a two-cycle or a four cycle model, look for oil fill or drain plugs on the crankcase. Oil is mixed with the gasoline on two-cycle engines, so they have no oil plugs. Two stroke engines run at a higher temperature than four stroke engines, so there is less thermal efficiency and a risk of fire. Two stroke engines also consume more oil and fuel than four stroke engines.

What’s the difference between two and four stroke engines? https://www.youtube.com/watch?v=0rza6B5mDQ4 (4 min)

Additional Video

How two and four stroke engines work https://www.youtube.com/watch?v=8dAbcbAJRw8 (12 min)

References:

– Heywood, John B. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 1988.

– Hillier, V. A., & Pittuck, P. (2006). Fundamentals of Motor Vehicle Technology. Nelson Thornes.

– Stone, Richard. Introduction to Internal Combustion Engines. Macmillan International Higher Education, 1999.

– Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson, 2003.