67 Troubleshooting Small Engines

Learning Objectives

Outcomes: Troubleshoot small engine problems

Key questions: An engine isn’t working, so what now?

Learning tasks: read online course material, perform troubleshooting on case studies

Topics: troubleshooting steps

Assessment: online quiz

Estimated time: 1.5 hours

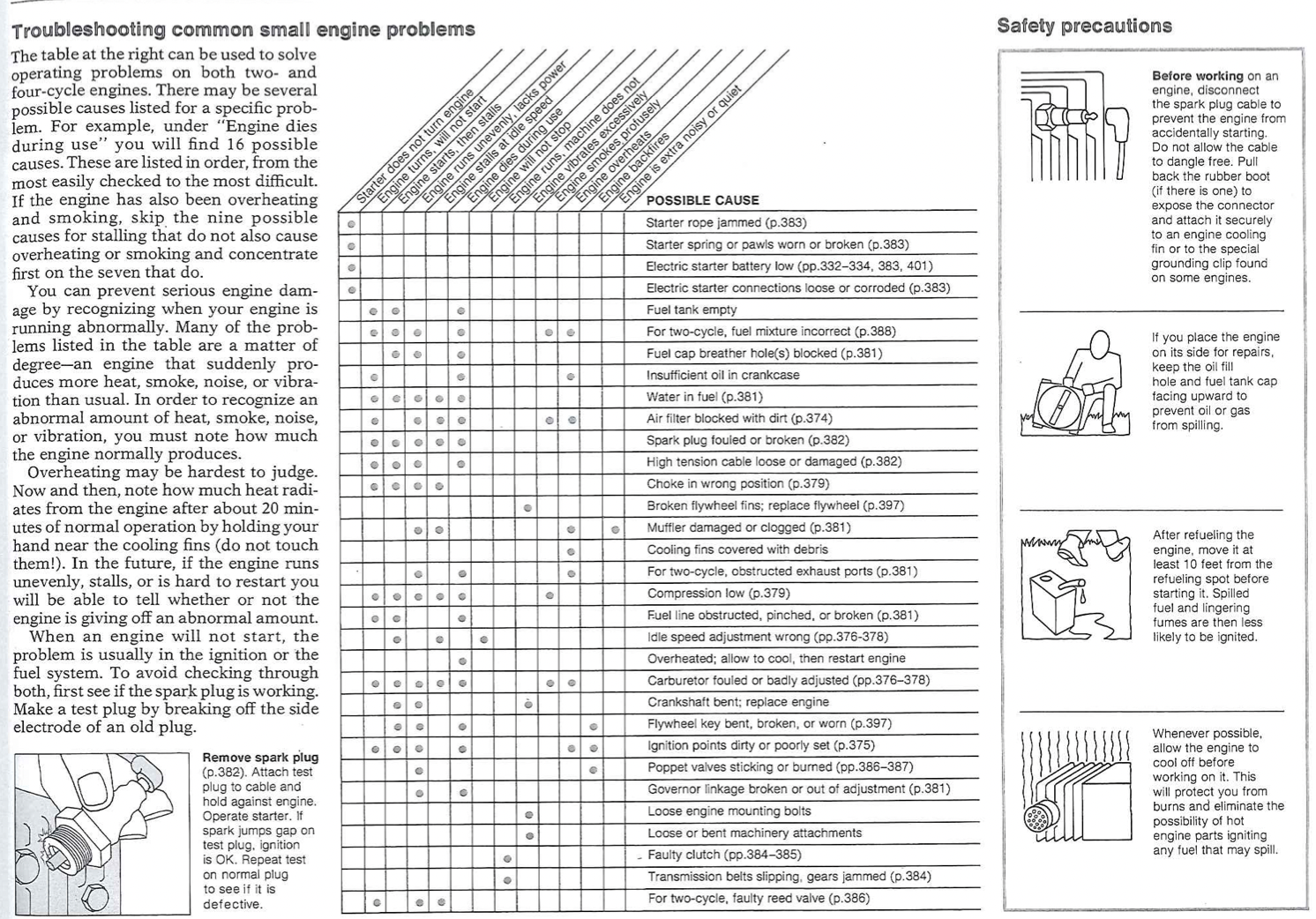

The following page includes a handy chart for diagnosing small engine issues. Along the top are common issues, and along the side are the probable causes. Once you isolate the cause of the engine’s issue, steps can be taken to repair it.

Troubleshooting Steps

Troubleshooting issues with both two-stroke and four-stroke engines involves a systematic approach to identify and resolve problems affecting their performance. Here are general troubleshooting steps:

Troubleshooting Steps:

1. Check for Fuel and Air: Ensure that the engine is receiving the proper fuel and air mixture. Check the fuel tank for sufficient fuel, and inspect the air filter for clogs or debris that may restrict airflow.

2. Inspect Spark Plug: Check the spark plug for signs of fouling, wear, or damage. Clean or replace the spark plug if necessary, and ensure that it is properly gapped according to the manufacturer’s specifications.

3. Examine Fuel System: Inspect the fuel lines, fuel filter, and carburetor for clogs, leaks, or other issues that may affect fuel delivery. Clean or replace components as needed, and ensure that the carburetor is properly adjusted.

4. Check Ignition System: Ensure that the ignition system is functioning properly. Test the ignition coil, ignition module, and other ignition components for continuity and proper operation.

5. Compression Test: Perform a compression test to check the engine’s compression levels. Low compression may indicate worn piston rings, cylinder scoring, or other internal engine problems.

6. Inspect Exhaust System: Check the exhaust system for blockages or restrictions that may affect engine performance. Clean or replace the exhaust muffler and remove carbon deposits from the exhaust ports as needed.

7. Verify Cooling System: Ensure that the engine is properly cooled to prevent overheating. Check the cooling fins, radiator (if applicable), and coolant level for signs of blockage or low coolant.

8. Evaluate Lubrication System: Verify that the engine is receiving proper lubrication to prevent excessive wear and friction. Check the oil level and inspect the oil pump and lines for leaks or blockages.

9. Perform Visual Inspection: Conduct a visual inspection of the engine and its components for signs of damage, leaks, or loose connections. Tighten loose bolts or nuts, and replace damaged parts as needed.

10. Examine Exhaust System: Inspect the exhaust system for blockages or restrictions that may impede engine performance. Clean or replace the exhaust muffler and remove carbon deposits from the exhaust ports as needed.

The following could be indications that there is an issue with an engine’s fuel delivery system:

- Difficulty starting

- Engine stalling or hesitation

- Rough running or misfiring

- Pack of power

- Fuel leaks

- Black smoke from the exhaust

- Engine overheating

- Poor fuel economy

- Engine dies under load

- Unusual engine sounds

Common issues with fuel systems in small engines can affect engine performance and reliability. Here are some common problems and how to diagnose them:

- Clogged Fuel Filter

A clogged fuel filter can restrict fuel flow to the engine, causing poor performance or stalling. To diagnose this issue, check the fuel filter for signs of clogging or debris buildup. If the filter is dirty or clogged, replace it with a new one. - Dirty Carburetor

Dirt, debris, or varnish buildup in the carburetor can obstruct fuel flow or disrupt the air-fuel mixture, leading to engine hesitation or rough running. To diagnose this issue, remove the carburetor and inspect it for signs of dirt or residue. Clean the carburetor thoroughly with carburetor cleaner and compressed air, and ensure that all passages and jets are clear. - Faulty Fuel Pump

A malfunctioning fuel pump can result in inadequate fuel delivery to the engine, causing starting problems or engine stalling. To diagnose this issue, check the fuel pump for proper operation and fuel flow. Test the fuel pump’s pressure using a fuel pressure gauge, and replace the pump if it is not delivering the correct pressure. - Fuel Contamination

Contaminated fuel, such as water or debris, can cause engine performance issues or damage fuel system components. To diagnose this issue, inspect the fuel tank and fuel lines for signs of contamination, such as water or sediment. Drain the fuel tank flush the fuel lines if contamination is present, and refill the tank with clean fuel. - Air Leaks

Air leaks in the fuel system, such as at the carburetor gasket or fuel lines, can disrupt the air-fuel mixture and cause engine running problems. To diagnose this issue, visually inspect the fuel system components for signs of leaks or damage. Use a carburetor cleaner or propane torch to detect air leaks by spraying or directing propane around the suspected areas while the engine is running. If the engine speed increases when propane is introduced, there may be an air leak. - Stale Fuel

Stale or old fuel can degrade over time, leading to starting difficulties or engine running issues. To diagnose this issue, check the condition of the fuel in the tank and inspect for signs of contamination or varnish buildup. If the fuel is stale, drain the fuel tank and refill it with fresh, high-quality fuel. - Fuel Line Blockage

Blockages in the fuel lines can restrict fuel flow to the engine, causing poor performance or stalling. To diagnose this issue, visually inspect the fuel lines for signs of kinks, bends, or obstructions. Use compressed air to blow out any debris or blockages in the fuel lines, and replace any damaged or kinked lines as needed.

The following are signs that there may be an issue with the engine’s ignition system:

- Difficulty starting

- Intermittent spark

- No spark

- Engine misfires

- Backfiring

- High fuel consumption due to incomplete combustion

- Engine stalling

- Engine overheating

- Visible damage to ignition components

- Check engine light

The following are some common issues with a small engine’s ignition system and how to diagnose them:

- Weak or No Spark

A weak or absent spark is a common issue that can prevent the engine from starting or cause it to run poorly. This could be due to a faulty spark plug, damaged ignition coil, or malfunctioning ignition module. To diagnose this issue, remove the spark plug and inspect it for signs of wear, fouling, or damage. Test the spark plug for spark by grounding the electrode against the engine block while cranking the engine. If there is no spark, check the ignition coil and ignition module for proper operation using a multimeter. - Improper Ignition Timing

Incorrect ignition timing can lead to poor engine performance, starting difficulties or engine knocking. To diagnose this issue, check the ignition timing using a timing light and compare it to the manufacturer’s specifications. Adjust the ignition timing if necessary by loosening the distributor clamp and rotating the distributor until the timing marks align correctly. - Faulty Ignition Switch

A faulty ignition switch can prevent power from reaching the ignition system, resulting in a no-start condition. To diagnose this issue, test the continuity of the ignition switch using a multimeter. If the switch fails to provide continuity in the ON position, it may need to be replaced. - Worn Ignition Wires

Worn or damaged ignition wires can cause electrical resistance and interfere with the flow of current to the spark plugs. To diagnose this issue, visually inspect the ignition wires for signs of cracking, burning, or damage. Test the resistance of the ignition wires using a multimeter, and replace any wires that exceed the manufacturer’s specifications. - Fouled or Dirty Spark Plugs

Fouled or dirty spark plugs can cause misfiring, poor engine performance, and difficulty starting. To diagnose this issue, remove the spark plugs and inspect them for signs of fouling, carbon buildup, or damage. Clean or replace the spark plugs as needed to restore proper ignition performance. - Faulty Ignition Coil

A faulty ignition coil can result in a weak or inconsistent spark, leading to engine misfires or starting difficulties. To diagnose this issue, test the ignition coil for proper resistance and output voltage using a multimeter. Replace the ignition coil if it fails to meet the manufacturer’s specifications. - Moisture or Corrosion

Moisture or corrosion in the ignition system can disrupt electrical connections and cause starting problems or engine stalling. To diagnose this issue, visually inspect the ignition components for signs of moisture or corrosion. Clean and dry the affected components, and apply dielectric grease to electrical connections to prevent future corrosion.

Video:

Diagnosing two stroke engines- https://www.youtube.com/watch?v=hHGSXrzYZZQ – 7 min

Diagnosing four stroke engines- https://www.youtube.com/watch?v=ZPFl7a-4kOM – 12 min

Safety Precautions

Before working on an engine, disconnect the spark plug cable to prevent the engine from accidentally starting. Do not allow the cable to dangle free. Pull back the rubber boot if there is one to expose the connector and attach it securely to an engine cooling fin or to the special grounding clip found on some engines.

If you place the engine on its side for repairs, keep the oil fill hole and fuel tank cap facing upward to prevent oil and gas from spilling

After refueling the engine, move it at least ten feet from the refueling spot before starting it. Spilled fuel and lingering fumes are less likely to be ignited.

Whenever possible, allow the engine to cool off before working on it. This will protect you from burns and eliminate the possibility of hot engine parts igniting any fuel that may spill.

References:

1. Paul Dempsey. “Small Engine Repair for Dummies.” John Wiley & Sons, 2004.

2. “Small Engine Repair Manual.” Haynes Manuals, 2019.

3. “Small Gas Engines.” Alfred C. Roth, James T. Lindemann, and Beverly L. Kirkpatrick. Goodheart-Willcox Publisher, 2011.