17 Electrical Generators

Electrical Generator Basics

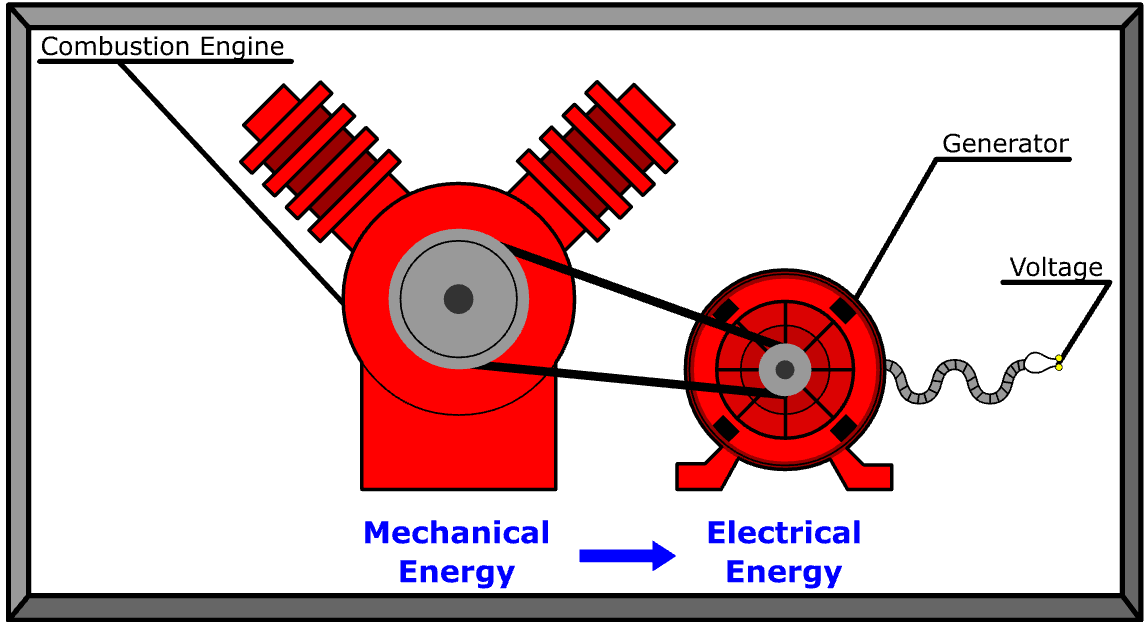

A generator is a machine that converts mechanical energy into electrical energy usin g the principle of magnetic induction.

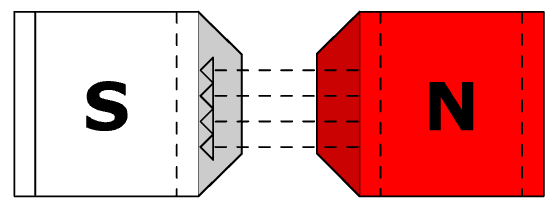

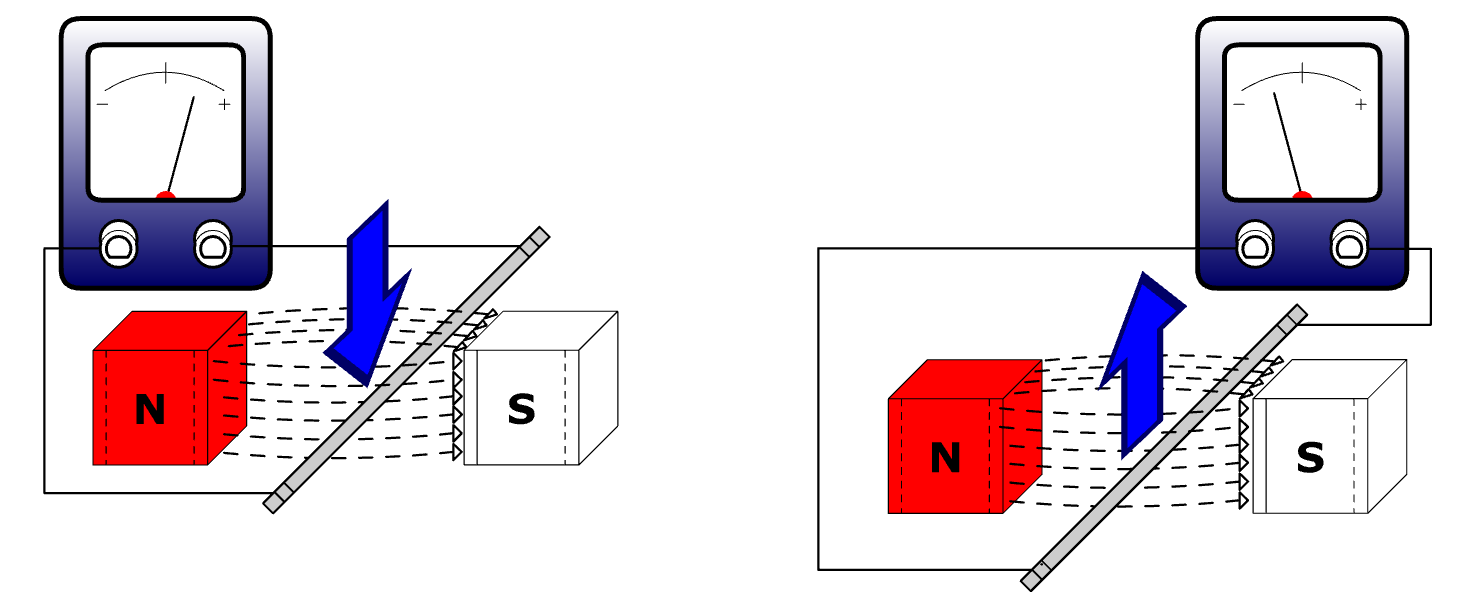

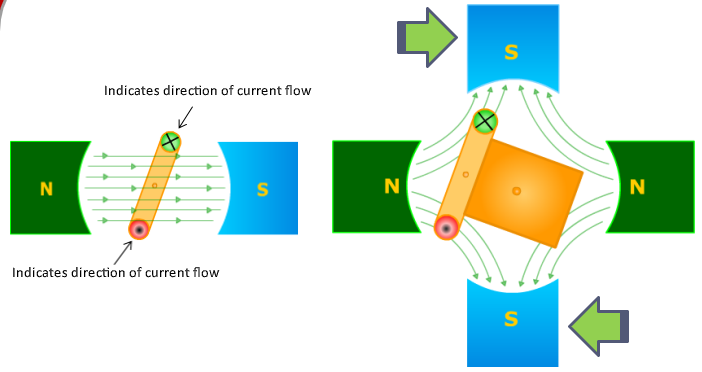

The principle is based on the fact that whenever a conductor cuts across the flux lines of a magnet, a voltage is generated in the conductor.

<insert electromagnetism video>

The amount of voltage generated depends on the following four factors:

- The strength of the magnetic field. A greater voltage is induced into a wire when it cuts through a stronger magnetic field.

- The angle at which the conductor cuts the flux lines. A greater voltage is induced into the wire when it cuts the flux at a right angle, than when it cuts them diagonally. If a wire goes in the same direction as the magnetic field, no voltage is induced at all.

- The speed at which the conductor cuts the flux lines. The voltage induced into the wire increases as it moves through the flux lines at a faster speed.

- The length of the conductor within the magnetic field. As the length of the wire that cuts through the magnetic field is increased, the voltage induced into it also increases. A wire loop that rotates through the flux lines has twice the length of a single straight wire that moves perpendicular through the lines. Therefore, the loop will produce twice the voltage as the single wire.

The polarity of the voltage depends on two factors:

- The direction of the magnetic flux lines, which travel from a north pole of one magnet to the south pole of another magnet.

- The direction at which the conductor cuts through the flux lines.

H5P questions

- An electrical generator converts _______ energy

- Mechanical energy into electrical

- Electrical energy into mechanical

- The _________ the flux lines determine the amount of voltage produced by an electrical generator.

- Strength of

- Angle at which the conductor cuts

- Speed at which the conductor cuts

- Length of the conductor cutting

- All of the above

The Elementary AC Generator

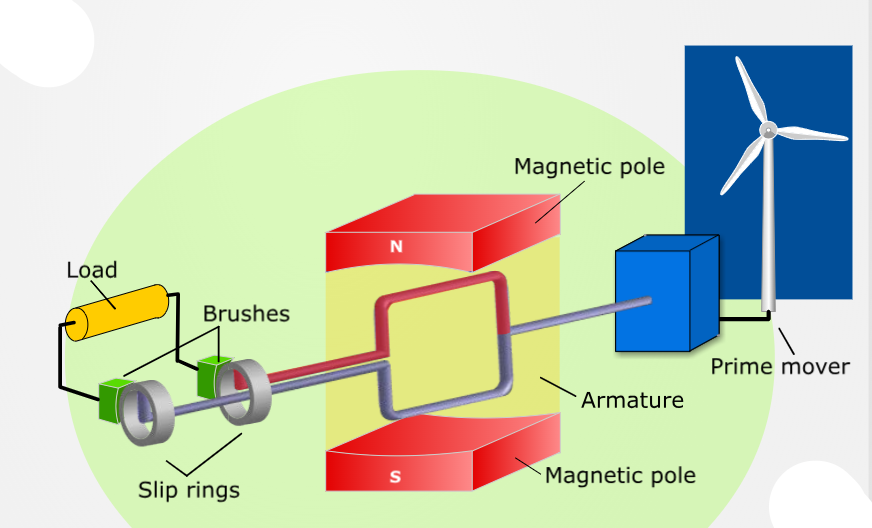

An electrical generator in its simplest form is a single loop of wire that rotates within a stationary magnetic field. The magnetic field is formed between two pole pieces, which are two magnets with opposite polarities.

The loop of wire that rotates through the field is called the armature. A device called a prime mover physically turns the armature. Different types of prime movers include:

- Combustion engines,

- Hydroelectric turbines,

- Wind turbines.

The ends of the armature loop are connected to rings called slip rings. They rotate with the armature.

As the armature rotates, carbon brushes ride against the slip rings. The generated voltage appears across these brushes and causes current to flow through a load. (A load is anything that consumes electricity.)

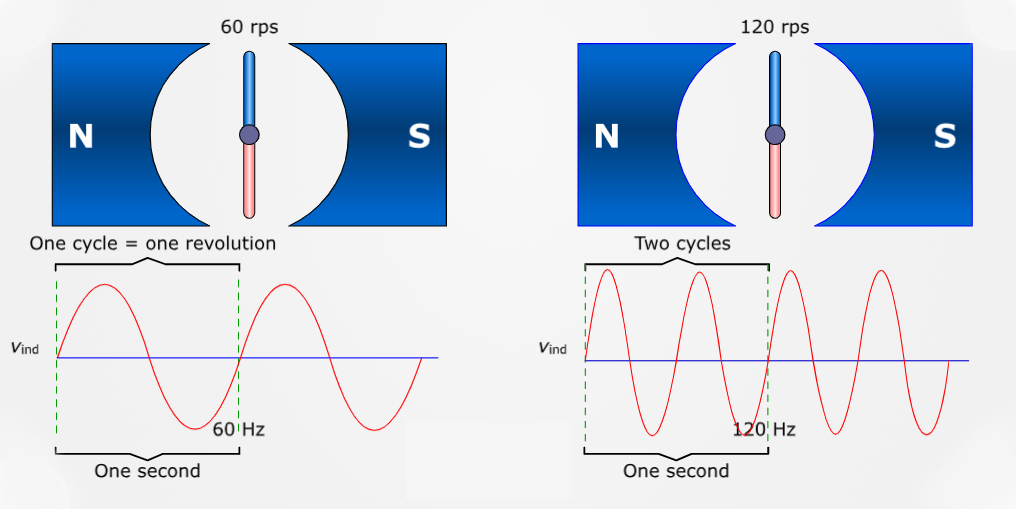

The frequency produced by the generator, which refers to the number of 360 degree rotations that occur each second, is determined by the speed at which the armature is turned by the prime mover. In North America, AC electrical frequency is 60 Hz, of 60 cycles per second.

Another factor affecting the frequency of alternating current is the number of poles in the generator.

Two generators are shown below. One generator has a single north pole and a single south pole, while the other generator has two north poles and two south poles.

H5P questions

- The _________ rotate(s) within the magnetic field

- Slip rings

- Brushes

- Armature

- The brushes of a generator make physical contact with _______ .

- Slip rings

- The armature

- Pole pieces

- At the instant the armature of a generator cuts through the magnetic flux lines at a right angle, the voltage produced is at its _________ .

- Minimum

- Maximum

- During the 360-degree rotation of a generator’s armature, the polarity of the voltage it produces ________ .

- Remains the same

- Reverses

- The frequency of a generator is determined by

- The number of stator poles

- The speed at which the rotor turns

- Both a and b

- When the rotors of two different generators turn at the same speed, the generator with the ________ number of poles will produce the higher frequency.

- Fewer

- Greater

The Three Phase AC Generator

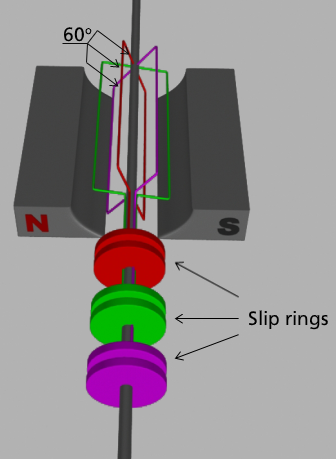

For applications that require more power, a three phase generator is most often used. The rotor of a three-phase generator, which consists of three loops of wire, is shown below. The loops are spaced 60 degrees apart and each end of the conductor is connected to its own slip ring.

H5P Questions

- Single phase generators typically produce _______ three phase generators

- Less power than

- More power than

- The same power as

- A three phase generator produces AC voltages that are ________ degrees apart.

- 60

- 120

- 180

Commercial Generators

Why Generators Are Important for Commercial Buildings?

No business wants to lose money due to unforeseen power outages. Unfortunately, losing money is exactly what happens when commercial buildings lose power and don’t have the backup plan needed to instantaneously restore services. Blackouts in commercial buildings can not only mean a loss in revenue, but it can also cause IT challenges, safety issues, security risks, and a reduction in customer trust for all types of businesses. These inconveniences and losses can be avoided with a properly installed and maintained generator that keeps the entire commercial building operating smoothly throughout the entire year.

Understanding the usefulness of a generator really comes down to understanding the power grid, and the events that can disable it.

How Power Grids Work

The power grid is the network that distributes electrical energy to all homes, business, and industries in Saskatchewan. It includes generator stations, transmission lines, towers, and individual consumer distribution lines.

Step 1: Energy is Generated The generator produces energy.

Step 2: Energy is Converted to High Voltage Convert energy into a high voltage for distribution.

Step 3: Distribution and Consumer Use Power lines deliver power to populated areas while transformers intersect the high voltage power and convert it back to a voltage that houses can use.

There are several ways we generate power. Coal, water, natural gas, nuclear, oil, and wind are all ways that we produce energy. In Saskatchewan most of our power generation comes from coal, and a portion comes from wind.

Coal is the world’s most abundant and cheapest fossil fuel, but it also releases the most pollution into our atmosphere. Coal is found in the south of the province, where most power generation occurs, so it is an economical and practical source of energy. Due to the quality of coal in the province, and new power generation technologies, the environmental impacts of coal power generation in Saskatchewan are minimized.

Wind power takes advantage of airflow to turn an electric generator. Although wind power is a variable power that depends on the weather, it is a stable source of energy over a long-term period. It is a reliable resource to meet power needs. One of the biggest downsides of wind energy is the noise and visual pollution. Wind turbines can be noisy when operating, expensive and wind is unpredictable.

Power Outages

There are several factors that can cause power outages in the province.

High Winds: Storms, tornadoes, and blizzards all have to possibility to damage property. High winds can pick up debris and fling it at buildings, homes, and power lines. It is easy for high winds to cause power loss to surrounding homes and businesses.

Heatwaves and Hot Weather: It is easy to imagine how much demand there is to fuel the army of A/C units in heatwaves. For the power plant, heat is a bigger issue. Hot weather makes energy generation less efficient. When there is a high demand, it plays a big role in what causes power outages in summertime.

Winter Storms: Severe winter storms can cause all kinds of danger. Low visibility, frostbite, hypothermia, loss of electricity, and risk of elderly and young children’s health contribute to the dangers of winter. Without power, pipes can freeze and heat quickly becomes a concern.

Ice: Power lines in winter may accumulate ice. When they do, ice forms in an upside down teardrop shape. The shape acts as a sail and makes the power lines sway in the wind. When the power lines sway, there is a possibility for them to make contact with each other and cause a fault or subsequent outage. In strong winds, the movement can also cause power line arms to break and the lines to fall to the ground.

Generator Configuration

Now that we know why generators are useful, how do they operate, and how are they built into the building systems?

The very basic operation of a generator is exactly what we learned in the first part of this chapter. In reality, industrial generators are large units located outside of the building because they are driven by some combustible fuel which needs good ventilation. Not to mention, generators can be very noisy!

Components of an Industrial Generator

To help you gain a better understanding of how an industrial generator works, we’ll take a closer look at the essential generator components and examine the role each plays in its operation:

Engine: The engine serves as the generator’s energy source — the larger the engine, the more power it is capable of supplying. Depending on the design, generators can operate on a variety of fuel sources such as diesel, natural gas, gasoline or propane.

Alternator: The alternator, often referred to as the genhead, is where the conversion from mechanical to electrical energy occurs. The alternator consists of stationary and moving parts that combine to produce the movement of the electrons.

Fuel system: The fuel system includes a tank that typically stores a six- to eight-hour supply of fuel, as well as a fuel pump, a pipe that runs from the tank to the engine and a return pipe.

Voltage regulator: This device controls the voltage of the electricity produced during generation and facilitates the conversion from AC to DC when necessary.

Cooling and exhaust systems: The cooling system prevents the generator from overheating during operation, while the exhaust system removes and disposes of the toxic fumes.

Lubricating system: This system contains and delivers the engine oil that ensures a smooth operation and prevents premature wear of the generator engine’s numerous moving parts.

Battery charger: Although an industrial generator operates via a fuel source, it requires battery power to start it up. The charger ensures the battery receives the necessary float voltage to maintain a sufficient charge.

Control panel: The control serves as the generator’s nerve center by managing every aspect of its operation. Depending on the generator model, the control panel may include features such as engine and generator gauges, phase selector switches and engine control switches.

Main assembly/frame: The frame provides the structure for the generator and houses and protects its vital components.

Switchgear

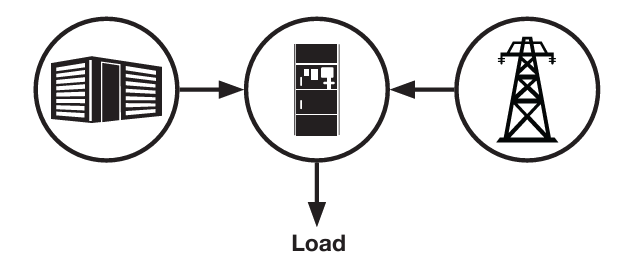

A permanent generator is typically wired into a commercial building’s electrical system via a generator transfer switch. During a power outage, the switches will isolate the “emergency” electrical wiring. Next, the generator will send power to select equipment until grid power is restored. Once the power has been restored, the switches will automatically turn off the generator.

A transfer switch is a device used for transferring power from one source to the other. The two sources can be defined as being similar sources of power (two utilities or two generators) or different sources of power (one utility and one emergency generator), but the basic function of the switch is to ensure that the loads are connected to an available source or the more reliable source. In the image below, a generator and the power grid connect to the transfer switch. The transfer switch connects to the load (building power).

Since it is the transfer switch that serves as a link to either power source, it can be considered one of the most critical links of a backup power system, as it is not just monitoring the sources, but is also making the critical decision of when to switch and which source it is to be connected to. The transfer switch controller determines if the primary source is good by checking the voltage and frequency of that source. When the control senses either the loss of the primary source and/or a change in voltage and/or frequency beyond a certain limit, it then immediately checks on the secondary source to make sure it is safe to transfer the loads on to the secondary source. In the case of the secondary source being a generator, it is the transfer switch that instructs the backup generator to start by sending a start signal to the generator control. The next step for the switch is to determine the correct time to transfer the load to ensure smooth and safe transition. All of this happens in a short period of time.

Types of Transfer Switches

There are different types of transfer switches offered by manufacturers to meet the different application and code needs. These types of transfer switches include:

Manual Transfer Switch: A manual transfer switch is one that requires a human interface to transition from one source to the other. These types of switches are ideal for non-critical loads and usually have a mechanical lever or an electrical mean for the person to operate this switch in the event of a power loss.

Automatic Transfer Switch: An automatic transfer switch (ATS), is a switch that makes use of electronics to continuously monitor the available sources and determine which source is ideal for providing power to the loads. Since these types of switches are equipped with their own control, it also automatically transitions load from one source to the other hence eliminating the need of a person to be present to perform a transfer.

Service Entrance Rated Transfer Switch: In the event of an emergency, it may be necessary for a first responder to quickly cut power to a building. This type of switch facilitates this situation.

Bypass Isolation Transfer Switch: In applications where even a momentary loss of power becomes critical for life and/or safety, such as hospitals or data centers or any emergency loads, the selection of bypass isolation switches may be necessary. A bypass isolation transfer switch has a secondary redundant circuit so power can flow when maintenance is being performed, or in event of failure, of the primary switch.

Generator Maintenance

Generators, typically powered by diesel engines, protect SIGA by restoring normal power when the regular power grid is disrupted due to bad weather or other disaster. In this vein, it is important to note that generators must be properly maintained throughout the year.

Maintaining a commercial building’s generator should occur not in the hours before a winter storm, but rather at regularly scheduled intervals. Maintenance not only reduces the risks of power failure, but it will also keep your generator operating safely and efficiently. In addition to conducting proper maintenance on your generator, a licensed and certified technician should run system tests to ensure that every aspect of the generator is working properly.

Generators, according to code, must be periodically run for an amount of time to test operation. Additionally, the cut over circuitry (switching the building from grid power to emergency power) needs to be tested to ensure emergency power can be safely delivered to the building in the event of a power outage.

When considering “the generator cannot ever go down” project parameter, the answer isn’t always to add more fuel. Fuel must be cleaned and maintained — commonly referred to as polishing — and the system must also have the varnish periodically removed. Factors such as representative service in the area, distance from the nearest fuel supplier or availability of fuel in the area need to be considered.

Essential and necessary maintenance generally consists of the following:

General inspection

Lubrication service

Cooling system service

Fuel system service (as mentioned above)

Battery testing

Engine exercise (as mentioned above)

Your basic maintenance includes checking the lubrication system, cooling system and fuel system. More advanced preventative maintenance includes taking oil and coolant samples to get them tested to see if there is any metal or debris in the sample. The readings can forecast failures and that can prevent extensive generator repairs. Batteries get old, belts and hoses deteriorate over time and critters can make a home inside a generator enclosure.

References

Information in this section has been quoted from the following websites:

https://www.wpowerproducts.com/blog/backup-power/generators-for-commercial-buildings/

https://nmccat.com/blog/rental/how-an-industrial-generator-works/

https://www.csemag.com/articles/considerations-for-emergency-generator-systems/

Understanding Power Outages, White Paper, Generac Industrial Power

The Basics of Selecting Transfer Switches, White Paper, Generac Industrial Power

A Quick Guide to Generator Maintenance, White Paper, Generac Industrial Power

11 Tings to Know When Owning & Operating a Standby Generator, Generac Industrial Power